The universe of turbomachinery consists of many different design concepts that are radically different from one another. Each class of machine has a particular flow and power range that is best suited for that design class. In general, a machine type that is not well suited to an application, cannot be refined sufficiently to perform well outside its normal range.

One classification of turbomachinery is the reaction. A turbomachinery stage can transfer energy through either a net change in the flow momentum or a net change in pressure. In most cases, some combination of the two is used. Machines that use pressure as the primary mechanism are called reaction types. Conversely, machines operating through a net change in momentum are called impulse types.

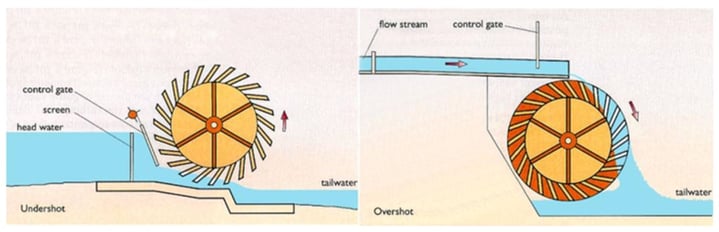

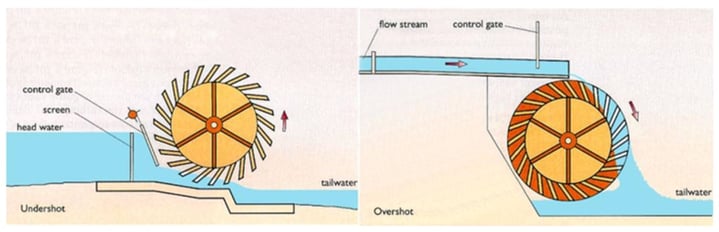

One of simplest and oldest styles of turbomachinery is the water wheel. The figure below on the left shows an impulse type design. The flow in either side of the wheel has, more or less, the same pressure, and the flow undergoes a net change in momentum. Of course, locally, there is a difference in pressure on the two sides of the paddles, but the net pressure change of the flow is zero. On the right, is the opposite reaction style of water wheel. The fluid reacts on the surfaces through a pressure difference, which is induced by gravity in this case.

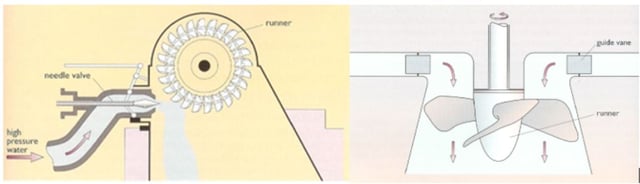

The impulse style of machine requires higher velocities to operate than a reaction type. Higher velocities have two important ramifications. One is the power density or amount of work extracted per flow rate of fluid can be quite high in a reaction machine. The second related effect is that high velocity inevitably, results in high losses and degraded efficiencies.

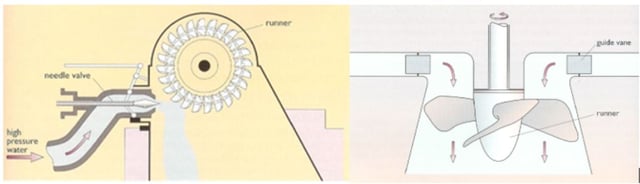

A less primitive application of these principles can be seen in the figures below. On the left is a Pelton wheel, used in high pressure and low-flow situations. It is a classic impulse style machine with large swings in the momentum of the jet but no net change in fluid pressure over the rotating component. In contrast, a propeller style turbine, on the right, has quite low velocities and operates primarily through a change of pressure.

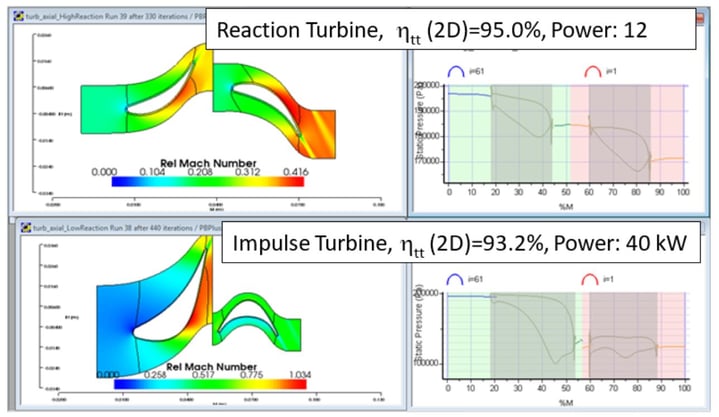

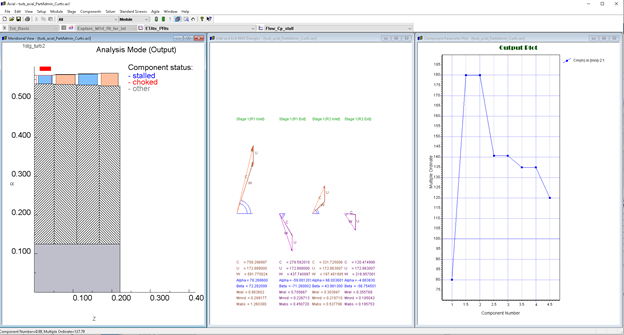

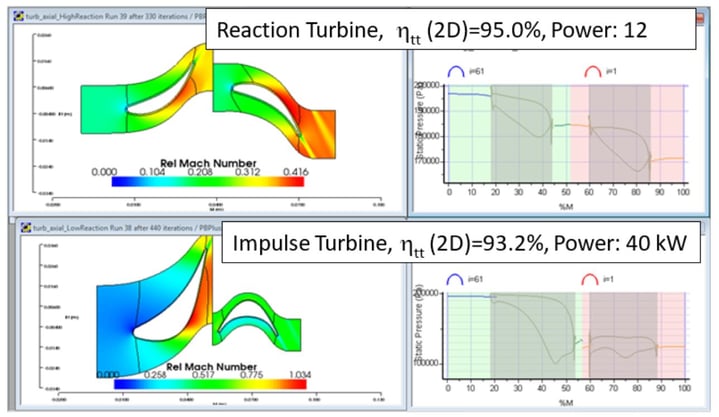

A modern demonstration of impulse versus reaction is an axial turbine design, seen below, which is shown in AxCent® 3D blade geometry software. Though the flow is high Mach number and compressible, the same principle applies. Note the reaction type machine at the top and the corresponding plot of pressure on the first stationary blade and second rotating blade. There is an overall pressure drop between the two blades, which is more or less evenly split. In contrast, the impulse type turbine on the bottom sees little pressure difference on either side of the second rotating blade element.

This modern example clearly shows the difference between the two design classes and the trade-off between performance and power density. In this case, one could simply layout three similar stages of a reaction design and extract the same amount of power as the impulse design, but this would come at significantly added cost and complexity.

In practice, the selection of reaction versus impulse is really a spectrum of application rather than a binary choice between the two. In fact, most designs have elements of the two. Ultimately, design choices such as these are determined by economic factors as much as technical ones.