Concepts NREC Announces New CEO

White River Junction, VT, USA – Jan 4, 2023 — Concepts NREC announced today that Dr. David Japikse, Founder, longtime Chief Executive Officer, and Chairman of the Board of Directors has retired from...

The latest in turbomachinery news from Concepts NREC

By Kate Guerrina, Marketing Manager

Nov 22, 2021

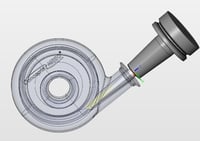

White River Junction, VT, USA – November 18, 2021 — Concepts NREC has expanded their portfolio of advanced manufacturing solutions for the turbomachinery industry to include 5-axis tube and port machining for volutes, housings, exhaust control systems, deep pockets, and manifolds.

Concepts NREC is pushing the edge of what is manufacturable by leveraging custom in-house tooling and highly efficient toolpaths to machine turbomachinery components that were previously thought to only be manufacturable as castings. Meeting the most demanding tolerances in aerospace alloys on tubular openings that change in shape and curvature from one end to the other while avoiding tool collisions is challenging, but to do so on high-performance or hot section turbomachinery applications upon which lives or payloads depend requires another level of precision machining.

“Clients in the aircraft and space exploration sectors are increasingly looking to Concepts NREC as a full-service solutions provider to build entire rigs including complex housings and volutes,” reports Mathew Cardente, Manufacturing Applications Specialist. “This new capability compliments our core competency in manufacturing advanced turbomachinery flowpath components such as impellers and rotors quite well as it allows us to manage the entire fit-up and assembly process with a high degree of quality, precision, and control.”

“This new capability provides a significant benefit to those customers looking for Concepts NREC to manufacture complete rig assemblies for research or production applications,” comments David Pincince, Business Development & Marketing Manager. “Our ability to control the entire process from initial design to final manufacturing and assembly provides unique synergies that few in the industry can offer. Our clients benefit from having a trusted partner who can see the big picture and provide them with valuable insights saving time and money.”

Concepts NREC has state-of-the-art 5-axis milling centers producing prototype and production hardware such axial and radial impellers, integrally shrouded impellers, turbines, individual airfoils, turbochargers, aero-engine blisks, and more up to 40” (1000mm) under our AS9100D certification and with lights out capabilities.

About Concepts NREC

For 65 years Concepts NREC has been a strategic partner to many of the world’s leading turbomachinery companies. We are the only company in the world offering a complete in-house turbomachinery solution from initial concept through design, manufacturing, and test, as well as integrated CAE and CAM software packages for industry. To learn more visit www.conceptsnrec.com

Tags: Manufacturing

By Kate Guerrina, Marketing Manager

Jan 4, 2023

White River Junction, VT, USA – Jan 4, 2023 — Concepts NREC announced today that Dr. David Japikse, Founder, longtime Chief Executive Officer, and Chairman of the Board of Directors has retired from...