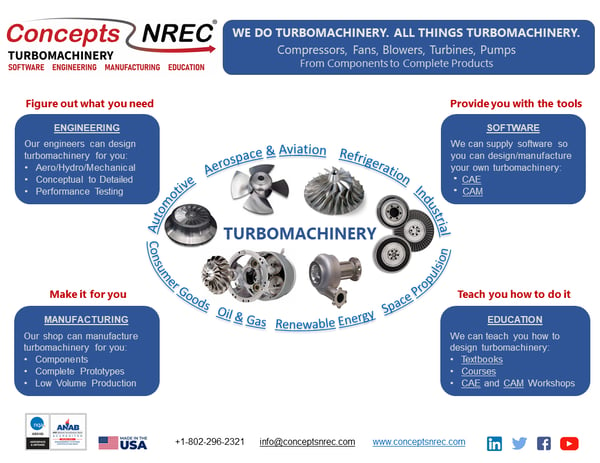

About Us

Advancing the State of the Art in Turbomachinery

Since 1956, Concepts NREC has been partnering with the world’s leading OEMs to improve the performance and manufacturability of their turbomachines. We are the only company in the world whose in-house capabilities span the entire process - from conceptual design through manufacturing, testing, and installation. This unique perspective creates powerful synergies that drive innovation across our entire offering. Our clients benefit from having a trusted partner who can see the big picture and provide valuable insights that save them time and money.

Concepts NREC maintains a robust in-house research and development program. We hold over 70 patents worldwide, with numerous patents pending. We push past what has been done to explore what can be done.

Concepts NREC is ISO 9001:2015 and AS9100:2016 certified and committed to providing our customers with products and services that meet international quality standards. Concepts NREC is also the leader of the global Advanced Centrifugal Pump and Compressor Consortium for Diffuser and Volute Design, an internationally sponsored research venture dedicated to advancing diffuser and volute design.

At Concepts NREC, we have the vision to create great designs, and a hard-earned reputation for delivering them.

Applied Research Program

Concepts NREC regularly conducts industry-sponsored consortia and internally funded projects that continue to expand our extensive knowledge and applied technology expertise.

Sponsors of Concepts NREC international consortia programs include equipment users, equipment manufacturers, government agencies, and independent research organizations. These collaborative, applied investigations generate important technical information and data on turbomachinery performance and reliability. Results are distributed exclusively to sponsors so they can improve product designs and resolve operational problems.

For over twenty years, consortium sponsors have received benefits that:

Privacy Notice

Concepts NREC respects your privacy and your personal data. We NEVER sell or share your data with anyone, unless you give explicit consent (such as when you purchase a textbook on this site through a third-party e-commerce vendor). Please read our Privacy Policy for more details.

Corporate Brochure

Improving the design and manufacturability of

compressors, pumps, gas turbines, steam turbines, fans, blowers, and turbochargers.