Oil & Gas

Concepts NREC can provide the oil and gas industry with software and engineering services for compressors for refining oil and gas, oil field pumps, gas transmission pipelines, pipeline compressors, and gas separation.

Related Products & Services

Technical Papers

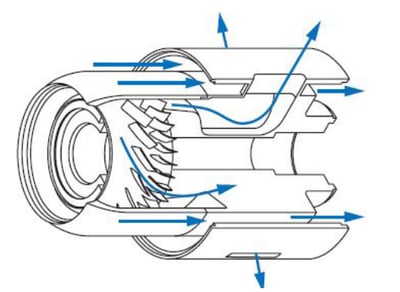

Development of A Meanline Model for Preliminary Design Of Recirculating Casing Treatment In Turbocharger Compressors

Presented At: ASME Turbo Expo 2018

A Novel Non-Radial Turbocharger Turbine Created Using Numerical Optimisation

Presented At: National Laboratory of Engine Turbocharging Technology of China 2016

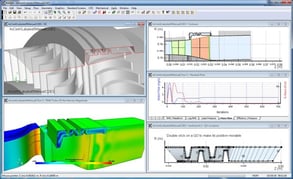

Designing Turbochargers with an Integrated Design System

Presented At: ASME Turbo Expo 2013

Turbocharging the Internal Combustion Engine - (Presentation Slides)

Presented At: ASME Turbo Expo 2013

Aero Design Challenges in Wide-Operability Turbocharger Centrifugal Compressors

Presented At: SAE World Congress 2012

Meanline Modeling of Ported Shroud Turbocharger Compressor

Presented At: ASME Turbo Expo 2012

Experimental and Computational Analysis of Impact of Self Recirculation Casing Treatment on Turbocharger Compressor

Presented At: SAE World Congress 2010

Modeling and Manufacturing of Turbocharger Compressors

Presented At: SAE World Congress 2010

Radial and Mixed Flow Turbine Options for High Boost Turbochargers

Presented At: 7th International Conference on Turbochargers and Turbocharging

Case Studies

Transportation

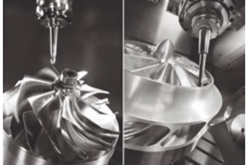

Concepts NREC designs, manufactures and tests turbochargers and turbocharger components for diesel and gasoline engines as well as compressor and turbine stages for gas turbine engines. We can also provide auxiliary system components for engines including fuel, oil and water pumps.

Waste Heat Recovery

Concepts NREC has extensive experience in the field of waste heat recovery, including providing ORC turbines for exhaust heat recovery from diesel and gas turbine engines.

Air, Land, Water

We cover the full range of transportation industries, including passenger cars, trucks, F1 racing, off-road vehicles, marine craft of all sizes, and aircraft piston, turbojet and turbofan engines.

Case Studies

- Chipco Manufacturing Optimizes Rail Impeller Milling with MAX-PAC™

- Daimler uses Concepts NREC Software to Develop Breakthrough Exhaust Gas Turbocharger

- Turbocharger Supplier CAM Software from Concepts NREC Slashes Turbocharger Development Time

- Volvo: RITAL™ Used for Turbocharged-Engine Simulations

Add to Cart

Resources

Axial Compressor Design Solution

Engineering Services

Manufacturing Services

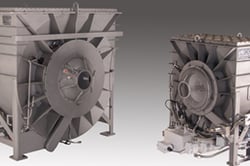

Air Dynamometer

Concepts NREC Develops, Manufactures, and Sells its Own Products

In addition to contract manufacturing complete turbomachinery products for customers, Concepts NREC manufactures and sells specialized turbomachinery products that serve well-defined niche applications.

These products are jointly developed with customers who first establish a market need for a new or improved technology. Concepts NREC then supplies the development expertise to turn their specification into a successful product. However, rather than just providing services for a fee, development costs are shared, enabling Concepts NREC to establish additional applications and markets for the product and generate noncompetitive sales. The results allow development costs to be amortized over larger production quantities, and both companies further benefit by producing a better product at a lower cost.

Proven Expertise

Agile Products Support (APS)

APS is Concepts NREC’s software maintenance and support program that elevates us from just a software provider to a valued partner.

An APS subscription is included with all annual licenses and is a highly-recommended option for perpetual software licenses. Every software customer is supported for one month following purchase for any installation questions that may arise. Learn more on the Agile Products Support Membership Benefits Datasheet.

- Free software updates

- One business day response times

- Expert technical assistance

- Major discounts on software workshops

- Discounted professional development course

- Annual balloting system for development planning

- Annual Meetings