Turbomachinery Manufacturing Services

Value-Added Turbomachinery Manufacturing Services

Concepts NREC’s manufacturing capabilities extend far beyond simply cutting metal. Our highly skilled machinists are backed by experienced design engineers with diverse technical backgrounds and software engineers who have produced industry-leading CAE and CAM programs.

This broad expertise enables us to suggest more efficient manufacturing methods, materials, processes, and designs that meet customer needs while lowering their production costs.

Concepts NREC’s state-of-the-art manufacturing center features 3- and 5-axis milling machines, horizontal and vertical numerical-controlled lathes, and high-end inspection equipment. Our specialty is delivering prototypes and short production runs of our clients’ most challenging turbomachinery parts.

Capabilities

Concepts NREC’s manufacturing capabilities extend far beyond simply cutting metal. Our highly skilled machinists are backed by experienced design engineers with diverse technical backgrounds and software engineers who have produced industry-leading CAE and CAM programs. This broad expertise enables us to suggest more efficient manufacturing methods, materials, processes, and designs that meet customer needs while lowering their production costs.

![]()

State-of-the-Art Machine Tools and Technologies

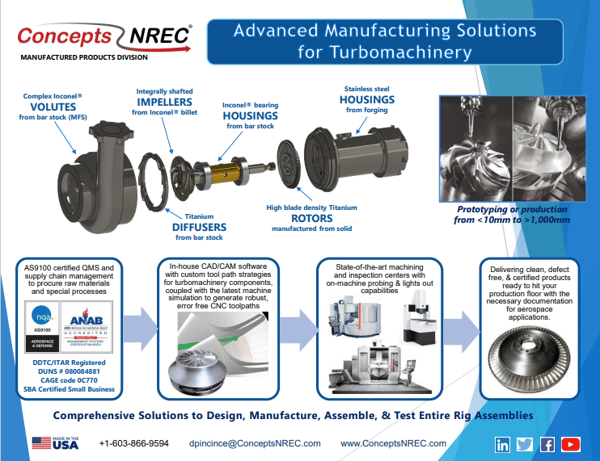

Concepts NREC operates a state-of-the-art product center capable of producing the highest-quality, precision-machined turbomachinery components and assemblies. Drawing on extensive experience and expertise with materials, industries, and technologies, Concepts NREC succeeds at complex component challenges that typically have been problematic for others.

This knowledge is supported by the latest manufacturing technologies that, combined, provide Concepts NREC with the credentials to meet the most exacting customer requirements across many industries including aerospace, energy, and industrial processing.

![]()

Capabilities

Manufacturing Capabilities Statement

- 5-axis machining of blades, blisks, inducers, propellers, impellers, and other turbomachinery parts

- Component assembly

- Concurrent manufacturing/engineering

- Coordinate Measuring Machine (CMM) inspection

- Dynamic balancing and modal analysis

- Inspection and testing to validate integrity and performance

- Machining complex shrouded (enclosed) impellers for pumps and compressors

- Prototypes and shorter production runs

- Reverse engineering of obsolete parts

Your Trusted Partner

Our design and manufacturing capabilities make us the first choice for many of the world’s leading manufacturers.

- Large OEMs trust us to concurrently engineer/manufacture the blisks and vanes for their newest product designs.

- International pump companies rely on us for our consistent quality and timeliness with their shrouded (enclosed) impellers.

- Users across a broad spectrum of industries leverage our expertise to reverse engineer obsolete turbomachinery parts.

- Early-stage start-ups work with us to build and improve their prototypes.

A clear and bold header

Capabilities

- 5-axis machining of blades, blisks, inducers, propellers, impellers, and other turbomachinery parts

- Component assembly

- Concurrent manufacturing/engineering

- Coordinate Measuring Machine (CMM) inspection

- Dynamic balancing and modal analysis

- Inspection and testing to validate integrity and performance

- Machining complex shrouded (enclosed) impellers for pumps and compressors

- Prototypes and shorter production runs

- Reverse engineering of obsolete parts

Your Trusted Partner

Our design and manufacturing capabilities make us the first choice for many of the world’s leading manufacturers.

- Large OEMs trust us to concurrently engineer/manufacture the blisks and vanes for their newest product designs.

- International pump companies rely on us for our consistent quality and timeliness with their shrouded (enclosed) impellers.

- Users across a broad spectrum of industries leverage our expertise to reverse engineer obsolete turbomachinery parts.

- Early-stage start-ups work with us to build and improve their prototypes.

What We Offer

Capabilities

- Simultaneous 5-Axis up to 39 in (99.06 cm) diameter

- Turning up to 39 in (99.06 cm) diameter

- CMM Inspection with Zeiss Blade Pro for in-depth dimensional analysis of turbine blades

- Assembly & Testing

Services

- Heat Treat

- Wire/Sinker EDM

- Spline/V-tooth/Drive Pins/Polygon

- Grinding

- Abradable Coating

- Brazing

- Polishing

- Shot Peening

- Paint

- Passivation

- Electroplating

- Welding

- Dynamic Balancing

- Overspeed Testing

- Liquid Penetrant Testing

- Ultrasonic Testing

- Laser Scanning

- Additive Manufacturing

Materials

- Aluminum

- Stainless Steel

- Inconel

- Titanium

Part Types

- Pump Impellers (open & integrally shrouded)

- Compressor impellers (open & integrally shrouded)

- Turbines rotors/impellers

- Blisks

- Housings/Volutes

- Bladed stators/guide vanes (IGVs)

- Diffusers

- Shrouds

Tolerances

- Dimensional to +/- 0.0001”

- Surface finishes to 8 µ in Ra

Trust the Experts in Turbomachinery

For over 60 years, we have helped leading global OEMs to improve the performance and manufacturability of their turbomachines.

This is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient.

Below is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient

Below is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient.

Below is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient.

Here are some quotes from our Customer Satisfaction Survey sent out after every job:

- "Customer service is really good - they answer questions and concerns in a timely manner."

- "High performance from quote to delivery"

- "Concepts' decision to stock material that is qualified to our specifications is a great competitive advantage. Their willingness to provide technical / commercial informational support makes them my "go-to" supplier for milled impellers."

State-of-the- Art Shop Tour

Agile Products Support (APS)

APS is Concepts NREC’s software maintenance and support program that elevates us from just a software provider to a valued partner.

An APS subscription is included with all annual licenses and is a highly-recommended option for perpetual software licenses. Every software customer is supported for one month following purchase for any installation questions that may arise. Learn more on the Agile Products Support Membership Benefits Datasheet.

- Free software updates

- One business day response times

- Expert technical assistance

- Major discounts on software workshops

- Discounted professional development course

- Annual balloting system for development planning

- Annual Meetings

Manufacturing Brochure

Our specialty is manufacturing prototypes and short production runs of your most challenging turbomachinery parts on our 5-axis CNC machines.