Turbomachinery Reverse Engineering

Reverse Engineering of Obsolete and Damaged Parts

As one of the world’s leading suppliers of comprehensive turbomachinery services, Concepts NREC has the engineering know-how, the depth of experience, the proprietary engineering software, and the complete facilities to reconstruct and often improve finished parts or assemblies.

Capabilities

Concepts NREC’s manufacturing capabilities extend far beyond simply cutting metal. Our highly skilled machinists are backed by experienced design engineers with diverse technical backgrounds and software engineers who have produced industry-leading CAE and CAM programs. This broad expertise enables us to suggest more efficient manufacturing methods, materials, processes, and designs that meet customer needs while lowering their production costs.

Quick-Turn Reverse-Engineered Parts

Requirements for reverse-engineered components come from widely diverse industries that use various types of turbomachinery, as well as unique needs that range from surgical replacement implants to automotive assemblies. Requirements are typically due to mechanical failure, performance failure, changes in policies or regulation, changes in a process, or the need for backup spares in a critical application. Concepts NREC can assist in solving both engineering and production problems by providing reverse-engineering solutions for:

- Manufacture of critical spares

- 3D prototype development and evaluation

- 2D drawing and technical documentation

- Prediction of reliability and life cycle analysis

- Qualification and compliance testing

High-Quality Results

- Detailed production drawings

- Existing spare parts

- Used, scrapped, and damaged components

- Partial contour or dimensional data

Re-Engineered for Better Performance, Life, Reliability, and Cost

- Older chillers converted to new fluids with no loss of performance (or improved performance)

- Clogging eliminated in petrochemical process pumps

- Turbocharger rerating to reduce emissions

- Compressor rerating to eliminate fatigue

Precision Inspection of the Existing Part

- Fourth-axis advantage means greater accuracy in less time

- Quality inspection data reduces project time

- Contour tolerances to 0.0001 inch or better

- Environmentally-controlled inspection room

Quick-Turn Reverse-Engineered Parts

Requirements for reverse-engineered components come from widely diverse industries that use various types of turbomachinery, as well as unique needs that range from surgical replacement implants to automotive assemblies. Requirements are typically due to mechanical failure, performance failure, changes in policies or regulation, changes in a process, or the need for backup spares in a critical application. Concepts NREC can assist in solving both engineering and production problems by providing reverse-engineering solutions for:

- Manufacture of critical spares

- 3D prototype development and evaluation

- 2D drawing and technical documentation

- Prediction of reliability and life cycle analysis

- Qualification and compliance testing

High-Quality Results

Fast turnaround of a reverse-engineered part or assembly for process resumption is also a key requirement when production is waiting on the replacement. Concepts NREC can create accurate components from a variety of source information:

- Detailed production drawings

- Existing spare parts

- Used, scrapped, and damaged components

- Partial contour or dimensional data

Re-Engineered for Better Performance, Life, Reliability, and Cost

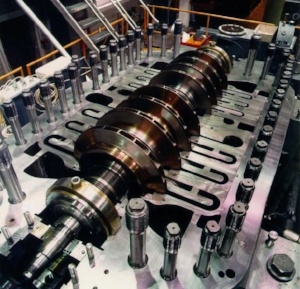

Quite often an obsolete impeller can be improved when being replaced. Engineered upgrades are typically designed for greater capacity, improved efficiency, changes in process, solving operating problems, or to avoid the replacement of expensive equipment. Examples of Concepts NREC re-engineering breakthroughs include:

- Older chillers converted to new fluids with no loss of performance (or improved performance)

- Clogging eliminated in petrochemical process pumps

- Turbocharger rerating to reduce emissions

- Compressor rerating to eliminate fatigue

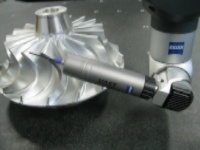

Precision Inspection of the Existing Part

Concepts NREC reverse engineering and re-engineering services include dimensional inspection with accurate data and interpretation by experienced turbomachinery engineers (who know exactly what contributes to measurement error). Using sophisticated Zeiss technology with fourth-axis rotary table capability permits extremely tight contours with a minimum of probe changes. Other features and benefits include:

- Fourth-axis advantage means greater accuracy in less time

- Quality inspection data reduces project time

- Contour tolerances to 0.0001 inch or better

- Environmentally-controlled inspection room

Experts in Prototyping Services

Concepts NREC manufacturing services include:

- Complex prototyping of machined wax patterns for precision investment castings

- Rapid prototyping of parts in stereolithography

- Geometric and manufacturing data preparation

- CNC machining instructions

- Process drawings and layouts

- Fixture and tool design

- Test-rig development

- Material and process specifications

- Assembly

- Inspection data analysis

Agile Products Support (APS)

APS is Concepts NREC’s software maintenance and support program that elevates us from just a software provider to a valued partner.

An APS subscription is included with all annual licenses and is a highly-recommended option for perpetual software licenses. Every software customer is supported for one month following purchase for any installation questions that may arise. Learn more on the Agile Products Support Membership Benefits Datasheet.

- Free software updates

- One business day response times

- Expert technical assistance

- Major discounts on software workshops

- Discounted professional development course

- Annual balloting system for development planning

- Annual Meetings

Manufacturing Brochure

Our specialty is manufacturing prototypes and short production runs of your most challenging turbomachinery parts on our 5-axis CNC machines.