As engineers planning and designing with CAD/CAM tools, we are developing processes in a theoretical world. It isn’t until you put on your boots, get in front of the machine, and start letting chips fly that you can start to see the effects of reality. Many times, this will reveal some unexpected challenges that require unique tools to solve them.

As engineers planning and designing with CAD/CAM tools, we are developing processes in a theoretical world. It isn’t until you put on your boots, get in front of the machine, and start letting chips fly that you can start to see the effects of reality. Many times, this will reveal some unexpected challenges that require unique tools to solve them.

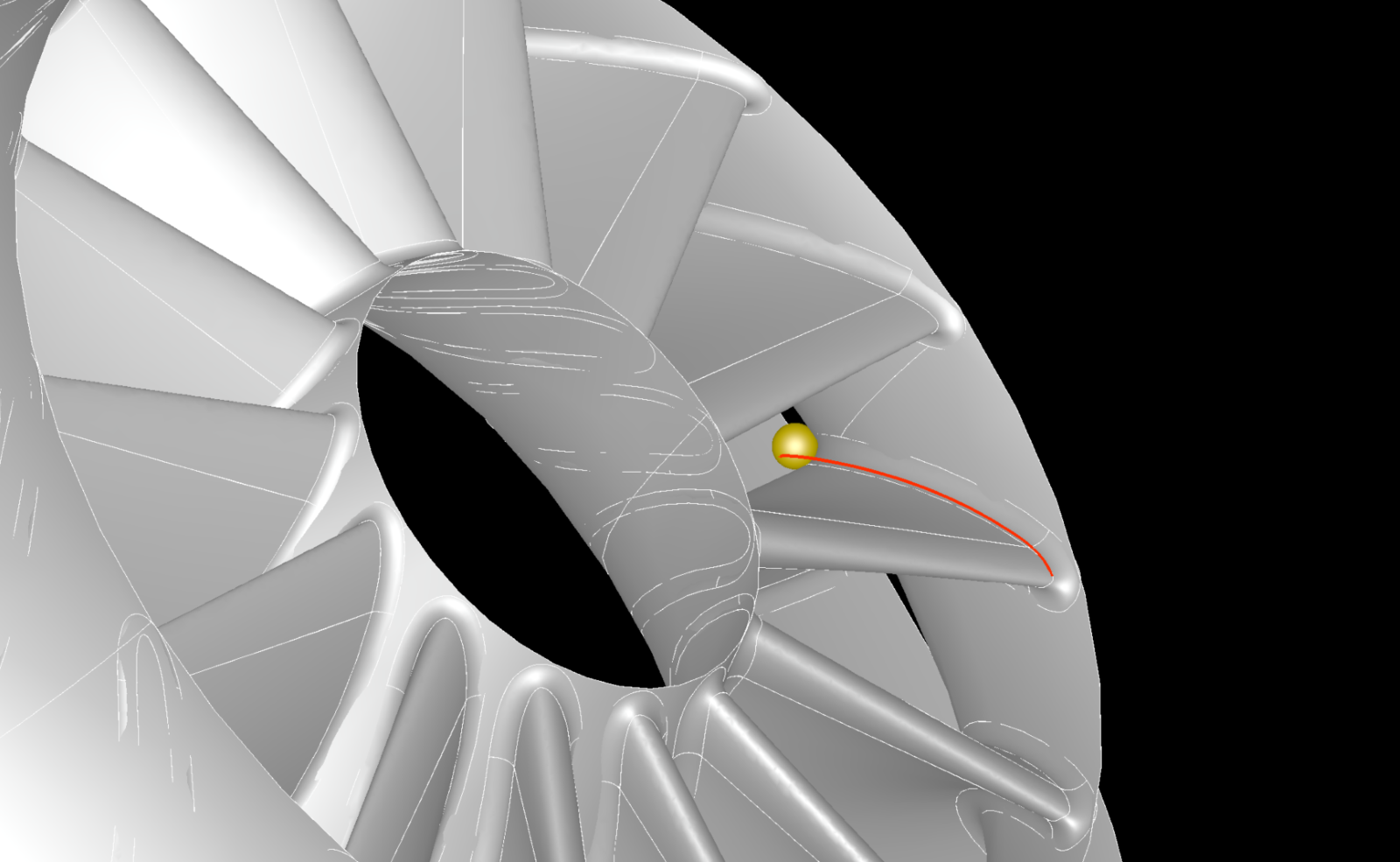

The first parts I remember working on as a manufacturing engineer were some small single vanes with a button at each end, relatively long and thin. Because of the lack of rigidity, we opted to use a tailstock to support the end that wasn’t fixtured. The buttons had a reasonable true position to each other as they needed to articulate in the test rig, so overall it didn’t seem like it should be an issue. After creating some meticulous programs with some tricky blends, we got out to the machine for some test cuts. The part looked great but as soon as you disengaged the tailstock the part sprang out of position by about an eighth of an inch! The joys of residual material stresses in action. One possible solution here is measuring the resulting form of the vane, and modifying the NC instructions to counter-act the deformation.

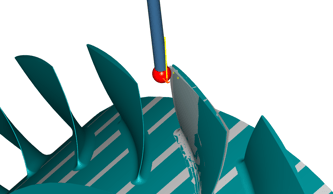

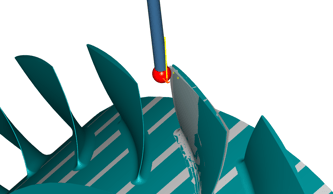

I also worked on some metal additive projects where we built complex parts via DMLS. On one project, we were able to meet surface roughness specs on the flow-path surfaces simply with an abrasive media process, but there were mechanical features and sealing surfaces that needed to be machined to meet functionality requirements. Of course, there were multiple positional requirements between all the finished surfaces and the flow path, so we had to solve the problem of fixturing the part in a way that aligned the printed surfaces with the finished machine surfaces. We ended up using on-machine probing and a best-fit algorithm to fine-tune the alignment of the part and meet some challenging tolerances.

This process of modifying the position or form of the machining instructions based on measured values is often referred to as adaptive machining.

This process of modifying the position or form of the machining instructions based on measured values is often referred to as adaptive machining.

Observing differences between theoretical space and reality is a common theme in process development, so as engineers we need tools to plan as much as possible and adapt when the problem can’t be designed or planned away. Whenever possible it is best to first try and solve these problems with process improvements before starting to manipulate the machining instructions. For example, form error can be caused by tool or set-up rigidity and can be solved by shortening tool extensions or revisiting fixture design. Residual stresses can sometimes be solved by allowing the part to relax after roughing operations and before starting finishing operations. Solving the problem in these ways isn’t always possible, which is when adaptive machining strategies are a great tool to have in your back pocket.

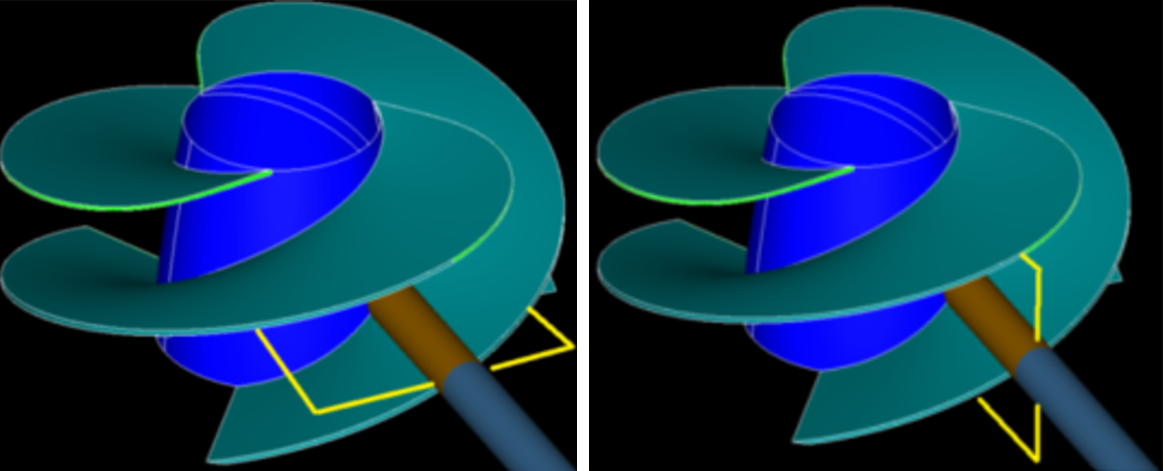

Challenges like this were common in my time as a manufacturing engineer and I’d say that overall, they fit into one of two categories – form error and positional error. With positional error, the overall problem to solve is what combination of translations and rotations will minimize error. With form error, you are instead trying to twist and distort the NC instructions to counteract the expected process effects. Each puzzle requires a separate adaptive machining tool to solve. By inspecting the part and analyzing the results you can work out which of these symptoms you have and select the appropriate adaptive tool to solve them.

If you are interested in learning more about how we solve these adaptive machining problems in MAX-PAC, please check out this webinar I did on our adaptive machining module. You can also find me on LinkedIn if you have questions or are interested in discussing adaptive machining applications.

We welcome your questions and comments here or contact us at info@conceptsnrec.com.

As engineers

As engineers  This process of modifying the position or form of the machining instructions based on measured values is often referred to as adaptive machining.

This process of modifying the position or form of the machining instructions based on measured values is often referred to as adaptive machining.