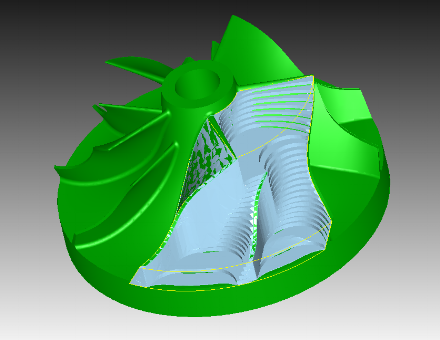

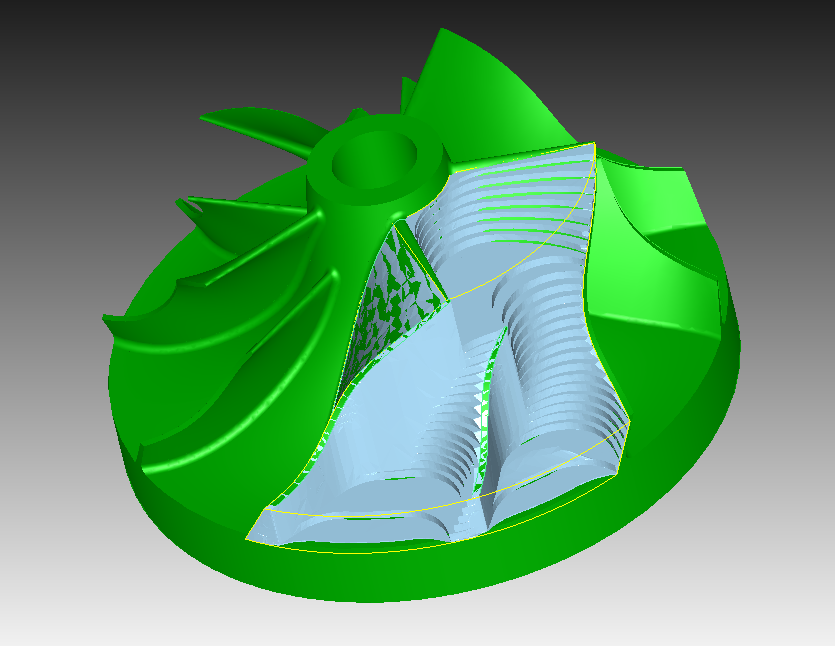

Evaluating Manufacturability for Shrouded Impellers

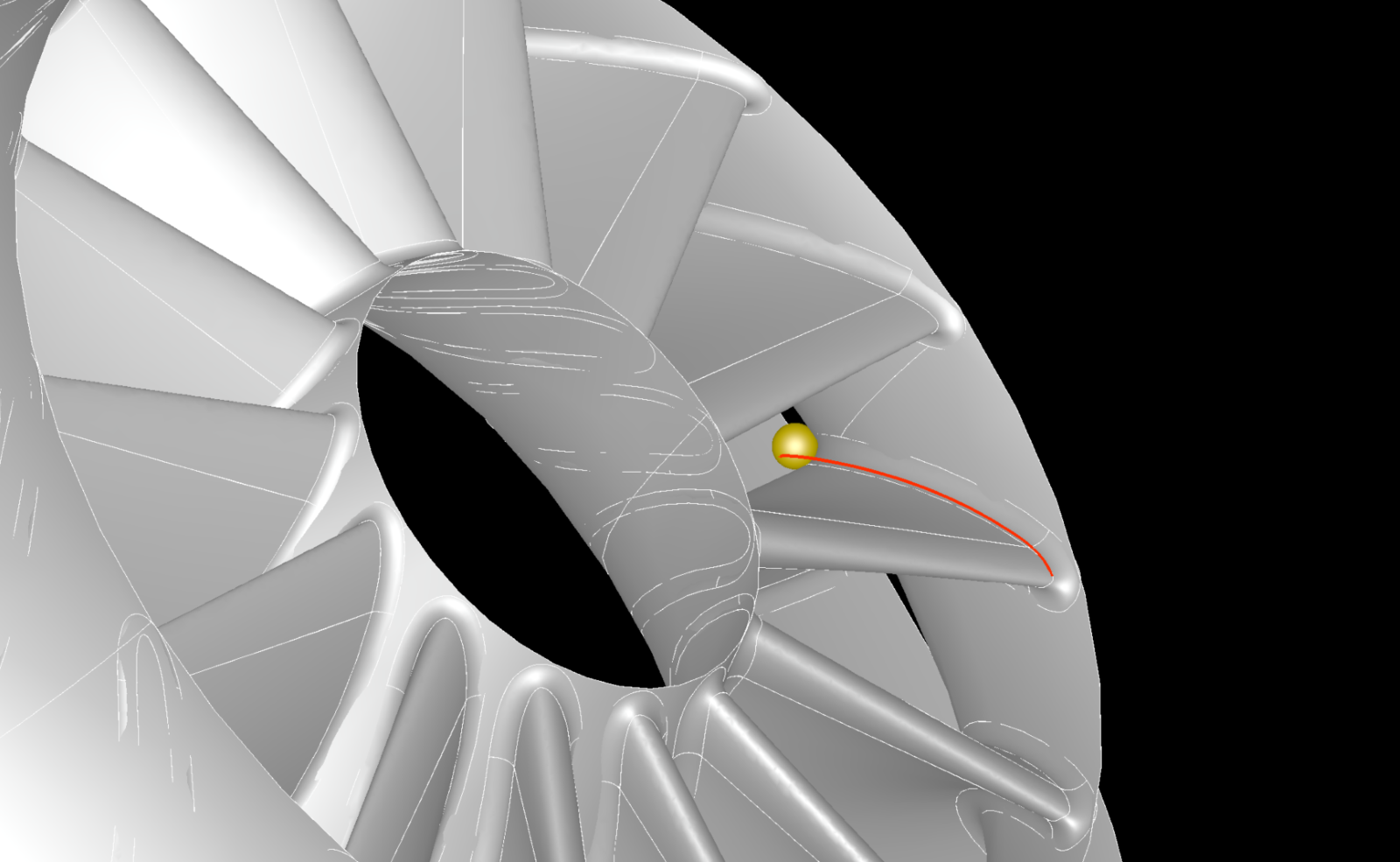

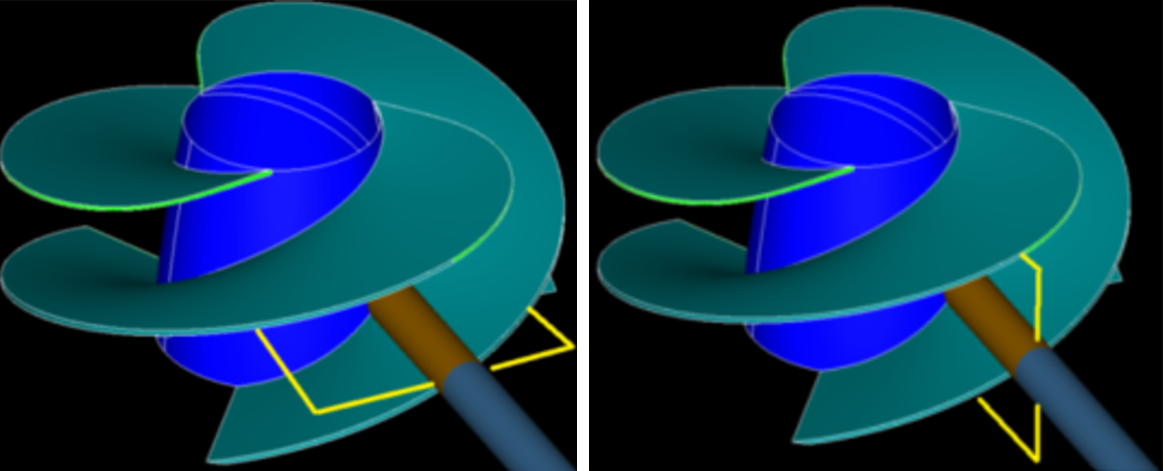

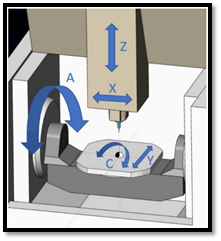

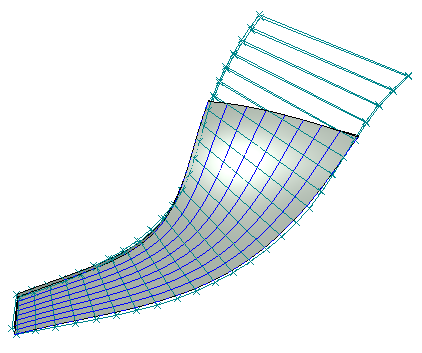

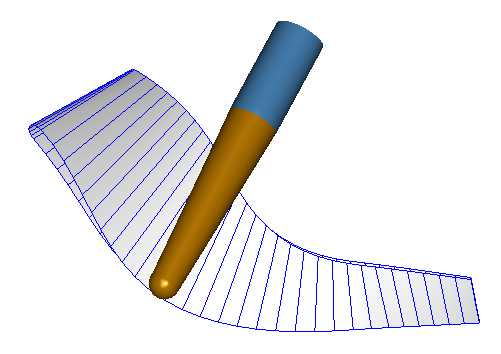

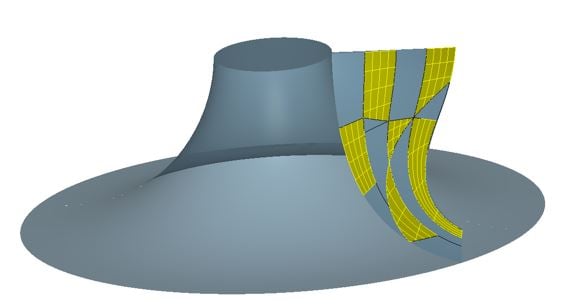

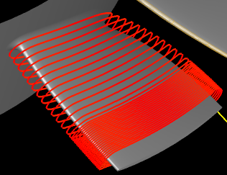

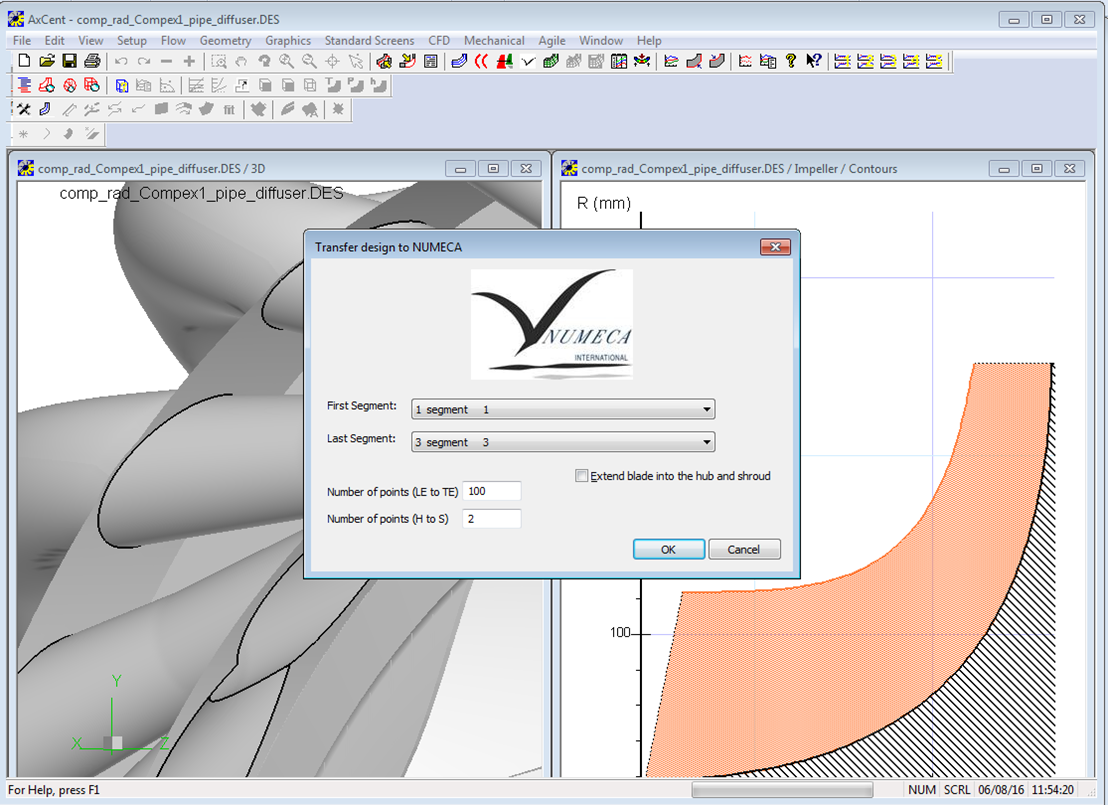

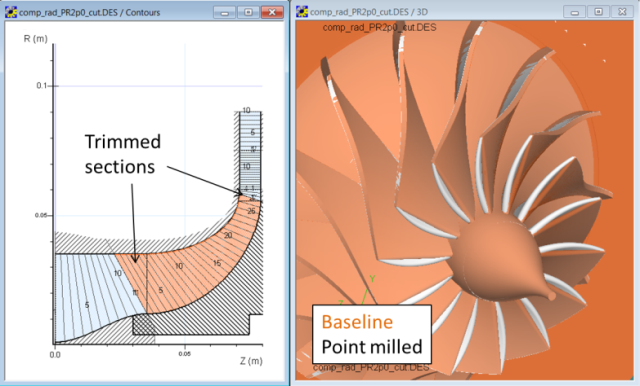

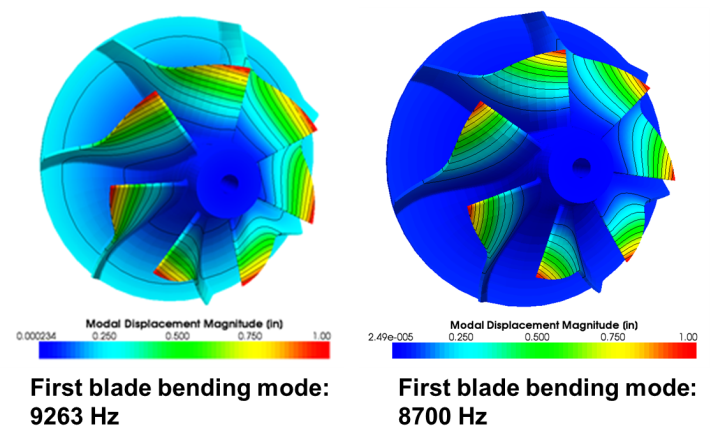

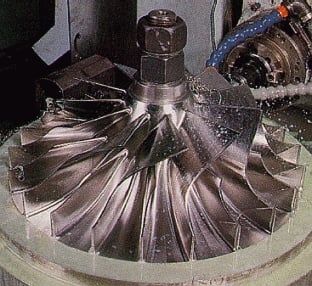

Design engineers are always looking for ways to push performance and efficiency. This can produce geometry which is challenging to machine and one of the first questions the manufacturing team needs...