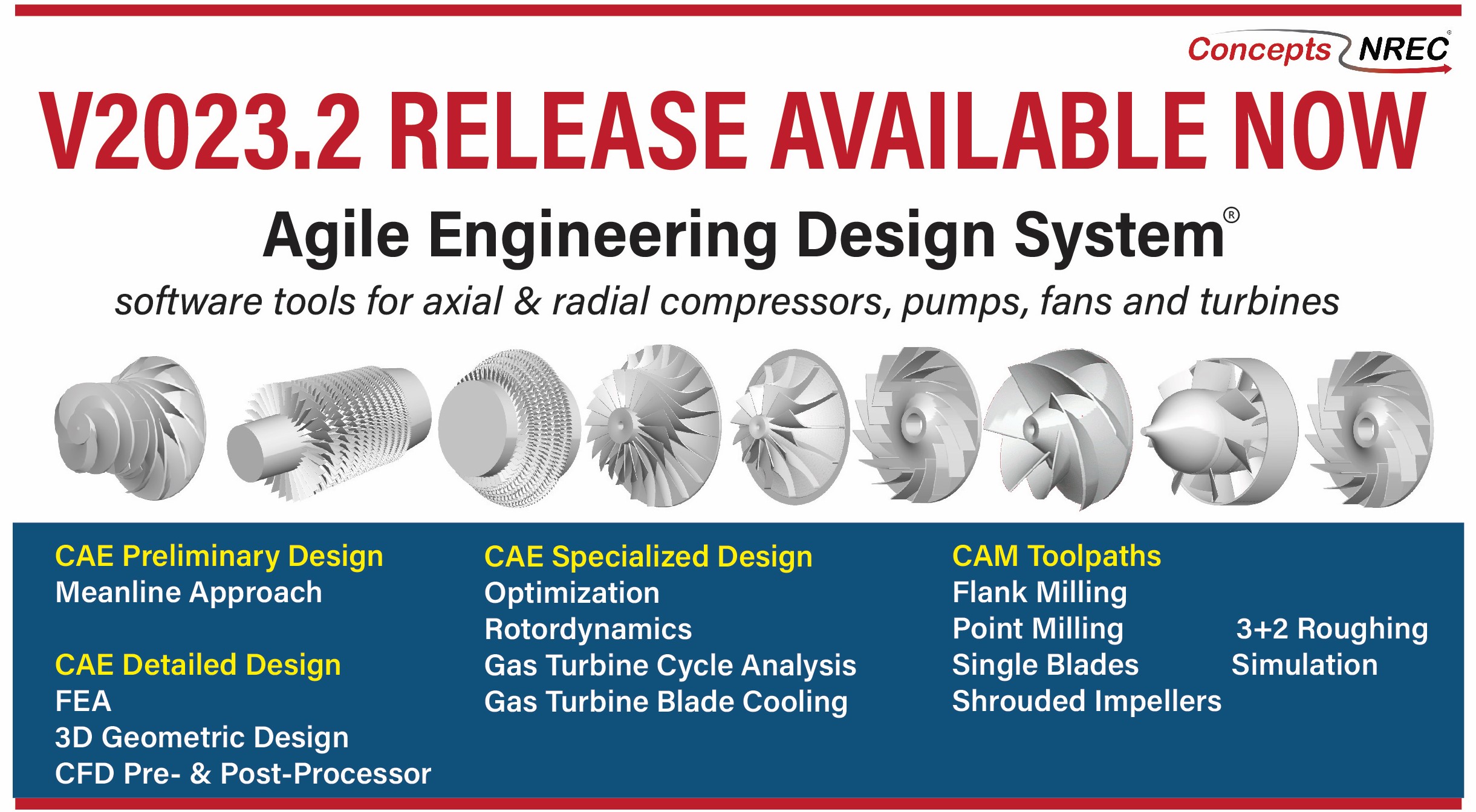

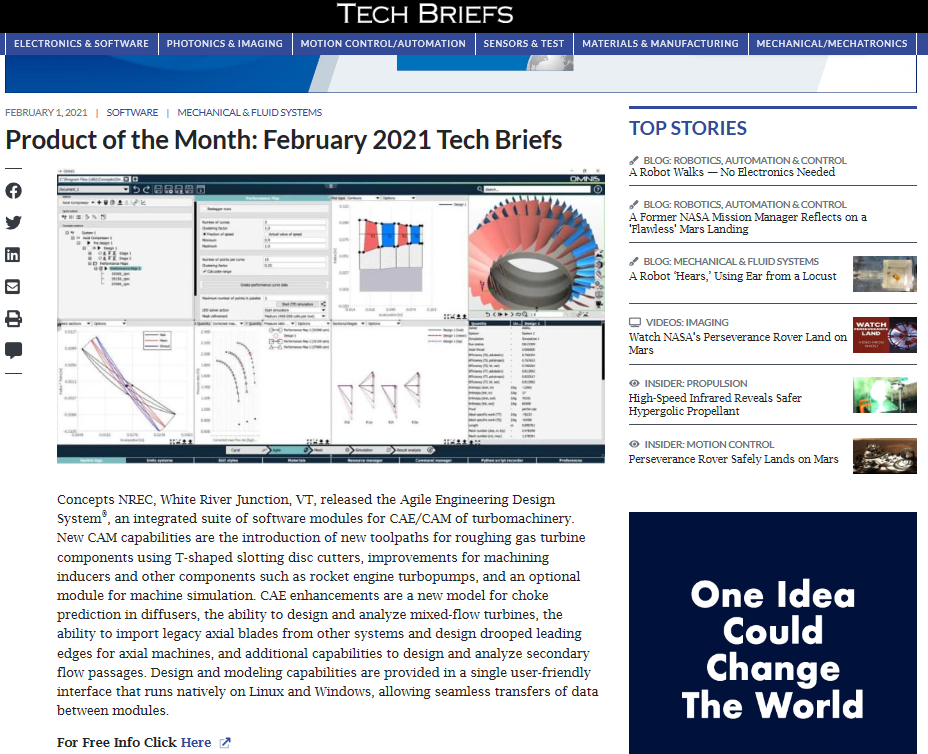

White River Junction, VT, USA – January 15, 2026— Concepts NREC, a global leader in end-to-end turbomachinery design and engineering solutions, is pleased to welcome Thomas Kudla, Senior Software...

Featured Post

Welcome Thomas Kudla, Senior Software Engineer at Concepts NREC

By Kate Guerrina, Marketing Manager

Jan 15, 2026