Laboratory Testing

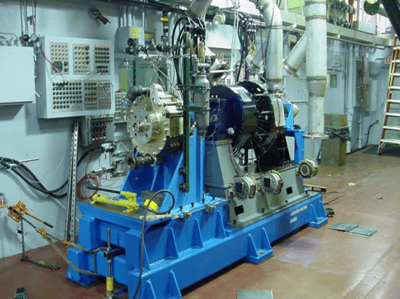

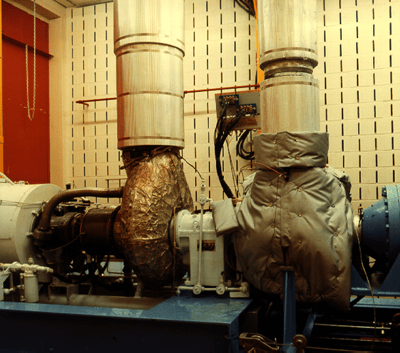

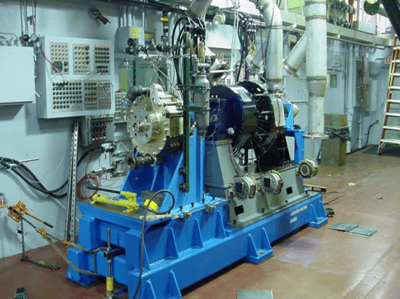

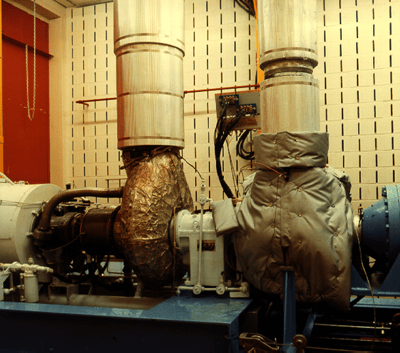

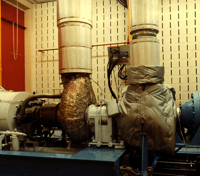

Concepts NREC operates extensive performance testing facilities to validate the operating specifications and design objectives of pumps, compressors, and turbines. Each of these facilities can adapt to a wide variety of requirements for evaluating both scale-model prototypes and full-dimension turbomachinery components and complete machines.

Extensive Testing Capabilities

Concepts NREC's test laboratories contain instrumentation from classical pneumatic and thermal probes and traverses to more sophisticated hot-wire/hot-film and laser anemometers, high frequency pressure transducers, and proximity probes. Data acquisition systems, laboratory software, flow traversing equipment, instrumentation devices (probes), and calibration services for various pressure and temperature probes are all available.

Flow, Pressure, Temperature, and Force Measurements

Concepts NREC has developed unique rigs for determining the forces and moments on rotating impellers, bearings, seals, couplings, and other components. These rigs provide a full suite of flow, pressure, temperature, and force measurements for an accurate characterization of performance and rotordynamic characteristics. Magnetic bearings precisely control the position and vibration of the component being tested, while documenting the fluid forces created either by movement or the operating load. Additionally, Concepts NREC has the capabilities for both static impeller modal testing and dynamic strain gage telemetry for mechanical assessment of compressors and turbines.

Using automated data-acquisition and reduction routines, Concepts NREC’s central data-acquisition facility can be configured to sequentially scan up to 144 pressures, 40 electrical signals, and 50 temperatures. This facility can acquire and analyze dynamic pressure signals and vibration sensors, as well as the scanned steady-state data. The laboratory data files that are generated can be used directly by other codes to process the traverse and impeller cover static pressure data. The data can also be automatically processed through Concepts NREC’s 1D meanline codes such as COMPAL® to generate full performance maps and detailed component aerodynamic performance parameters.

-

Concepts NREC's test laboratories contain instrumentation from classical pneumatic and thermal probes and traverses to more sophisticated hot-wire/hot-film and laser anemometers, high frequency pressure transducers, and proximity probes. Data acquisition systems, laboratory software, flow traversing equipment, instrumentation devices (probes), and calibration services for various pressure and temperature probes are all available.

-

Concepts NREC has developed unique rigs for determining the forces and moments on rotating impellers, bearings, seals, couplings, and other components. These rigs provide a full suite of flow, pressure, temperature, and force measurements for an accurate characterization of performance and rotordynamic characteristics. Magnetic bearings precisely control the position and vibration of the component being tested, while documenting the fluid forces created either by movement or the operating load. Additionally, Concepts NREC has the capabilities for both static impeller modal testing and dynamic strain gage telemetry for mechanical assessment of compressors and turbines.

Concepts NREC has developed unique rigs for determining the forces and moments on rotating impellers, bearings, seals, couplings, and other components. These rigs provide a full suite of flow, pressure, temperature, and force measurements for an accurate characterization of performance and rotordynamic characteristics. Magnetic bearings precisely control the position and vibration of the component being tested, while documenting the fluid forces created either by movement or the operating load. Additionally, Concepts NREC has the capabilities for both static impeller modal testing and dynamic strain gage telemetry for mechanical assessment of compressors and turbines.Using automated data-acquisition and reduction routines, Concepts NREC’s central data-acquisition facility can be configured to sequentially scan up to 144 pressures, 40 electrical signals, and 50 temperatures. This facility can acquire and analyze dynamic pressure signals and vibration sensors, as well as the scanned steady-state data. The laboratory data files that are generated can be used directly by other codes to process the traverse and impeller cover static pressure data. The data can also be automatically processed through Concepts NREC’s 1D meanline codes such as COMPAL® to generate full performance maps and detailed component aerodynamic performance parameters.

Concepts NREC's test laboratories contain instrumentation from classical pneumatic and thermal probes and traverses to more sophisticated hot-wire/hot-film and laser anemometers, high frequency pressure transducers, and proximity probes. Data acquisition systems, laboratory software, flow traversing equipment, instrumentation devices (probes), and calibration services for various pressure and temperature probes are all available.

|

|

|

|

Concepts NREC has developed unique rigs for determining the forces and moments on rotating impellers, bearings, seals, couplings, and other components. These rigs provide a full suite of flow, pressure, temperature, and force measurements for an accurate characterization of performance and rotordynamic characteristics. Magnetic bearings precisely control the position and vibration of the component being tested, while documenting the fluid forces created either by movement or the operating load. Additionally, Concepts NREC has the capabilities for both static impeller modal testing and dynamic strain gage telemetry for mechanical assessment of compressors and turbines.

Concepts NREC has developed unique rigs for determining the forces and moments on rotating impellers, bearings, seals, couplings, and other components. These rigs provide a full suite of flow, pressure, temperature, and force measurements for an accurate characterization of performance and rotordynamic characteristics. Magnetic bearings precisely control the position and vibration of the component being tested, while documenting the fluid forces created either by movement or the operating load. Additionally, Concepts NREC has the capabilities for both static impeller modal testing and dynamic strain gage telemetry for mechanical assessment of compressors and turbines.

Using automated data-acquisition and reduction routines, Concepts NREC’s central data-acquisition facility can be configured to sequentially scan up to 144 pressures, 40 electrical signals, and 50 temperatures. This facility can acquire and analyze dynamic pressure signals and vibration sensors, as well as the scanned steady-state data. The laboratory data files that are generated can be used directly by other codes to process the traverse and impeller cover static pressure data. The data can also be automatically processed through Concepts NREC’s 1D meanline codes such as COMPAL® to generate full performance maps and detailed component aerodynamic performance parameters.

Extensive Testing Capabilities

Concepts NREC's test laboratories contain instrumentation from classical pneumatic and thermal probes and traverses to more sophisticated hot-wire/hot-film and laser anemometers, high frequency pressure transducers, and proximity probes. Data acquisition systems, laboratory software, flow traversing equipment, instrumentation devices (probes), and calibration services for various pressure and temperature probes are all available.

Flow, Pressure, Temperature, and Force Measurements

Concepts NREC has developed unique rigs for determining the forces and moments on rotating impellers, bearings, seals, couplings, and other components. These rigs provide a full suite of flow, pressure, temperature, and force measurements for an accurate characterization of performance and rotordynamic characteristics. Magnetic bearings precisely control the position and vibration of the component being tested, while documenting the fluid forces created either by movement or the operating load. Additionally, Concepts NREC has the capabilities for both static impeller modal testing and dynamic strain gage telemetry for mechanical assessment of compressors and turbines.

Using automated data-acquisition and reduction routines, Concepts NREC’s central data-acquisition facility can be configured to sequentially scan up to 144 pressures, 40 electrical signals, and 50 temperatures. This facility can acquire and analyze dynamic pressure signals and vibration sensors, as well as the scanned steady-state data. The laboratory data files that are generated can be used directly by other codes to process the traverse and impeller cover static pressure data. The data can also be automatically processed through Concepts NREC’s 1D meanline codes such as COMPAL® to generate full performance maps and detailed component aerodynamic performance parameters.

Find Your Rep

Our Sales Offices are strategically located around the globe to service all your turbomachinery needs.

Corporate Headquarters

217 Billings Farm Road

White River Junction, VT 05001-9486

Phone: 802-296-2321

Fax: 802-296-2325

Email: sales@conceptsnrec.com

North America Software Sales

Phone: 802-280-6181

Fax: 802-296-2325

Email: droberson@conceptsnrec.com

Upcoming Events

Tradeshows, Workshops, Webinars and more.

2021 Online Centrifugal and Axial Pumps Course - Modern Design, Performance, and Problem Solving

Application-Based Learning

Date: October 18 - 29, 2021

Time: 9:30 am - 1:00 pm EDT

Course Fee: $3500 USD

This course is designed to help engineers design, test, and run pumps and systems that are more efficient, more economical, and more reliable. Engineers will come to understand the best state-of-the-art design practices and learn the latest theories on performance, cavitation, dynamic forces, and noise. The course will review the latest advances in design tools and will provide expert and relevant instruction to designers on pump design optimization. Nearly half of all the teaching is focused on actual commercial design cases with measured data for confirmation.

2021 Trade Show: ComVac Asia

Visit Concepts NREC China at the ComVac Asia

Date: October 26-29, 2021

Location: Shanghai, China

To learn more, visit https://www.comvac-asia.com/index.php?lang=en

2021 Online Centrifugal and Axial Pumps Course - Modern Design, Performance, and Problem Solving

Application-Based Learning

Date: October 18 - 29, 2021

Time: 9:30 am - 1:00 pm EDT

Course Fee: $3500 USD

This course is designed to help engineers design, test, and run pumps and systems that are more efficient, more economical, and more reliable. Engineers will come to understand the best state-of-the-art design practices and learn the latest theories on performance, cavitation, dynamic forces, and noise. The course will review the latest advances in design tools and will provide expert and relevant instruction to designers on pump design optimization. Nearly half of all the teaching is focused on actual commercial design cases with measured data for confirmation.

Corporate Brochure

We push past what has been done to explore what can be done. Concepts NREC has the vision to create great designs and a hard-earned reputation for delivering them.

I came to the realization that we needed some objective insight.

We were working well with the OEM but even with our combined efforts, we were struggling to get a critical compressor to pass performance on their test stand. Although I'd never directly done business with Concepts NREC I was familiar with them and their capability so I chose to contact them when I came to the realization that we needed some objective insight. Concepts NREC fielded my cold call and immediately engaged their expertise in a complex problem that was also challenged by schedule constraints. They provided increased understanding of an already complex CFD which resulted in increased confidence that the proposed solution would succeed on the next test stand attempt (which it did!). We are pleased to have had the help of Concepts NREC and now have a well-performing compressor in our process.”

Bryan Barrington

Senior Advisor - Machinery Engineering