Turbomachinery Design Engineering

Comprehensive Engineering Solutions For Turbomachinery Design

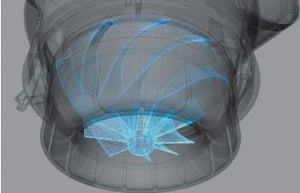

Our highly-trained engineering team works closely with you to understand your performance, reliability, manufacturability, and cost goals. Concepts NREC analyzes alternative design approaches and provides vital insight into the interdependencies between hardware design and operating requirements. We suggest improvements, develop designs, supply retrofit components, and provide complete equipment solutions.

Proven Expertise

Concepts NREC's engineering consulting services can supplement and support your in-house capabilities with world-class technology, specialized methods, and proven experience in fluid mechanics, heat transfer, combustion, applied mechanics, production, and system controls. Our engineers work closely with you to understand and resolve various performance, structural, and rotordynamic problems in individual machines, entire turbomachinery trains, or complete plant systems.

Concepts NREC helps you solve difficult engineering problems to improve the efficiency, performance, and manufacturability of your compressors, pumps, turbines, fans, blowers, and turbochargers. We can work from existing specifications or only a statement of the desired requirements.

Services We Offer

Review Services

Laboratory Testing

Fundamental Research

Services We Offer

Agile Products Support (APS)

APS is Concepts NREC’s software maintenance and support program that elevates us from just a software provider to a valued partner.

An APS subscription is included with all annual licenses and is a highly-recommended option for perpetual software licenses. Every software customer is supported for one month following purchase for any installation questions that may arise. Learn more on the Agile Products Support Membership Benefits Datasheet.

- Free software updates

- One business day response times

- Expert technical assistance

- Major discounts on software workshops

- Discounted professional development course

- Annual balloting system for development planning

- Annual Meetings

Corporate Brochure

Our integrated design and manufacturing software tools provide designers with a cost-effective, concurrent development approach that balances issues of performance, reliability, cost-effectiveness, and manufacturability.

Learn More about Turbomachinery Design in Our SpinOffs Blog.

Advanced Diffuser & Volute Design Consortium

Contact Us

Americas, India & SE Asia

Mr. David Pincince

Concepts NREC

Phone: 603- 866-9594

Fax: 802-296-2325

Email: dpincince@conceptsnrec.com

Greater China

Mr. Peng Wang

Concepts NREC

Mobile: +86 186 1128 2696

Email: pwang@conceptsnrec.com

EMEA

Japan

Mr. Motonari Takahashi

Daiichi System Engineering (DSE)

6F Nittochi Nagoya Bldg. 2-1-1,

Sakae, Naka-ku, Nagoya City,

Aichi 460-0008 Japan

Phone: 81-52-857-1715

Fax: 81-52-857-1711

E-mail: sales-CN@dse-corp.co.jp

South Korea

Dr. Hoyoun Kim

KIMHUA Technologies, Inc.

4F, Sema B/D, 535, Eonju-ro,

Gangnam-gu, Seoul, 06138 Korea

Phone: 82-02-556-1257

Fax: 82-02-556-4020

Email: hykim@kimhua.co.kr

“We were working well with the OEM but even with our combined efforts we were struggling to get a critical compressor to pass performance on their test stand. Although I'd never directly done business with Concepts NREC I was familiar with them and their capability so I chose to contact them when I came to the realization that we needed some objective insight. Concepts NREC fielded my cold call and immediately engaged their expertise in a complex problem that was also challenged by schedule constraints. They provided increased understanding of an already complex CFD which resulted in increased confidence that the proposed solution would succeed on the next test stand attempt (which it did!). We are pleased to have had the help of Concepts NREC and now have a well-performing compressor in our process.”

Bryan Barrington, Senior Advisor - Machinery Engineering