Your Trusted Partner

Whether you design and manufacture turbomachinery

components in-house, or outsource part or all of the process,

we help you achieve optimum performance.

Latest News & Events

News

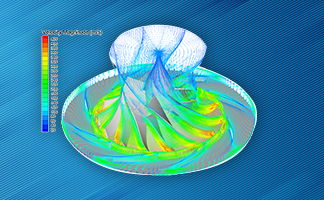

Agile Engineering Design System® v2025.2 Released: New capabilities for volute modeling, secondary flows, and optimized manufacturing

October 21, 2025

News

New Software Modules and New/Improved Integrations - Concepts NREC Releases v2025.1 of the Agile Engineering Design System

April 3, 2025

News

Concepts NREC and ADS CFD Announce Strategic Partnership to Bring Blazing Fast GPU Accelerated CFD to Turbomachinery Design

April 2, 2025

News

Ansys and Concepts NREC Introduce Automated Workflow for Turbomachinery Design and Analysis

February 12, 2025

Turbomachinery Experts

Total turbomachinery resource

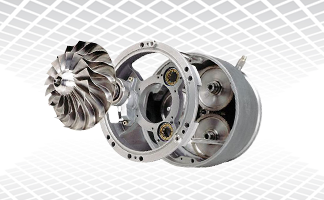

- Engineering Design Services - Aero, Hydrodynamic, Mechanical, Rotordynamic, Structural, and Thermodynamic

- Laboratory Testing and Complete Rig Assembly

- Resources for Turbochargers and Supercritical CO2 Systems

- Application Specific CAE Software Solutions

- CAM Software Solutions with Machine Simulation

- Portable Air Dynamometers for Testing Turboshaft Engines

- Advanced 5-Axis Manufacturing of Rotating Bladed Flowpath Components

- Advanced Engineering Courses and Textbooks

Industries We Serve: