Rocket Turbopumps

Conventional Rocket Turbopumps

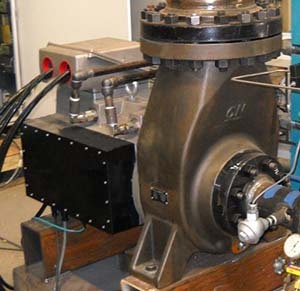

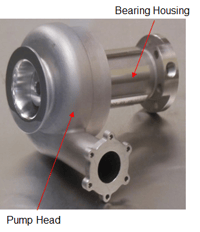

Conventional rocket turbopumps use a turbine driven pump for pumping and pressurizing both fuels and oxidizers. Concepts NREC has extensive experience in the design of rocket turbopumps and turbopump components. We manufacture these components as well as complete rocket turbopump assemblies and systems for research or production applications.

We can design a rocket turbopump to your specifications, develop, test, and manufacture the pump in production quantities. We support development testing for both hydrodynamic as well as mechanical components.

See links for more background on our engineering design and design software capability.

Add/replace with shop tour video hosted on Youtube

Capabilities

Concepts NREC’s manufacturing capabilities extend far beyond simply cutting metal. Our highly skilled machinists are backed by experienced design engineers with diverse technical backgrounds and software engineers who have produced industry-leading CAE and CAM programs. This broad expertise enables us to suggest more efficient manufacturing methods, materials, processes, and designs that meet customer needs while lowering their production costs.

![]()

State-of-the-Art Machine Tools and Technologies

Concepts NREC operates a state-of-the-art product center capable of producing the highest-quality, precision-machined turbomachinery components and assemblies. Drawing on extensive experience and expertise with materials, industries, and technologies, Concepts NREC succeeds at complex component challenges that typically have been problematic for others.

This knowledge is supported by the latest manufacturing technologies that, combined, provide Concepts NREC with the credentials to meet the most exacting customer requirements across many industries including aerospace, energy, and industrial processing.

Conventional Rocket Turbopumps

Conventional rocket turbopumps use a turbine driven pump for pumping and pressurizing both fuels and oxidizers. Concepts NREC has extensive experience in the design of rocket turbopumps and turbopump components. We manufacture these components as well as complete rocket turbopump assemblies and systems for research or production applications.

We can design a rocket turbopump to your specifications, develop, test, and manufacture the pump in production quantities. We support development testing for both hydrodynamic as well as mechanical components.

See links for more background on our engineering design and design software capability.

E-pumps

Electric driven pumps, often called e-pumps, are becoming more popular for smaller sized rocket propulsion in situations where launch system cost and simplicity are of paramount importance. E-pump design considerations include optimum suction performance, efficiency, weight and cost.

Electric driven pumps, often called e-pumps, are becoming more popular for smaller sized rocket propulsion in situations where launch system cost and simplicity are of paramount importance. E-pump design considerations include optimum suction performance, efficiency, weight and cost.

We have an e-pump prototype which has been tested with several propellants and can be customized to run a wide range of head/flow conditions. The pump can be modified with alternate bearings and seals for non-cryogenic service.

This e-pump prototype is currently being used by several clients in development projects for aerospace applications and for cryogenic service in space.

Why e-pumps?

- Simplifies the pump

- No hot turbine

- Speed match between the pump and turbine no longer a concern

- Easier to control the pump speed, and hence where the pump operates

- Eliminates large temperature gradients between the hot turbine and cold pump

- Simplifies the engine

- At current battery energy/power density levels, e-pumps make sense for smaller engines (5-10K lbf thrust)

Concepts NREC has been active in the e-pump arena for 10 years with prior in-depth experience researching and developing conventional rocket turbopumps.

Please contact us to discuss how we can help with your specific rocket turbopump or e-pump design or manufacturing needs.

Concepts NREC is ISO 9001:2015 and AS9100:2016 certified and committed to providing our customers with products and services that meet international quality standards.

What We Offer

Capabilities

- Simultaneous 5-Axis up to 39 in (99.06 cm) diameter

- Turning up to 39 in (99.06 cm) diameter

- CMM Inspection with Zeiss Blade Pro for in-depth dimensional analysis of turbine blades

- Assembly & Testing

Services

- Heat Treat

- Wire/Sinker EDM

- Spline/V-tooth/Drive Pins/Polygon

- Grinding

- Abradable Coating

- Brazing

- Polishing

- Shot Peening

- Paint

- Passivation

- Electroplating

- Welding

- Dynamic Balancing

- Overspeed Testing

- Liquid Penetrant Testing

- Ultrasonic Testing

- Laser Scanning

- Additive Manufacturing

Materials

- Aluminum

- Stainless Steel

- Inconel

- Titanium

Part Types

- Pump Impellers (open & integrally shrouded)

- Compressor impellers (open & integrally shrouded)

- Turbines rotors/impellers

- Blisks

- Housings/Volutes

- Bladed stators/guide vanes (IGVs)

- Diffusers

- Shrouds

Tolerances

- Dimensional to +/- 0.0001”

- Surface finishes to 8 µ in Ra

E-pumps

Electric driven pumps, often called e-pumps, are becoming more popular for smaller sized rocket propulsion in situations where launch system cost and simplicity are of paramount importance. E-pump design considerations include optimum suction performance, efficiency, weight and cost.

We have an e-pump prototype which has been tested with several propellants and can be customized to run a wide range of head/flow conditions. The pump can be modified with alternate bearings and seals for non-cryogenic service.

This e-pump prototype is currently being used by several clients in development projects for aerospace applications and for cryogenic service in space.

Why e-pumps?

- Simplifies the pump

- No hot turbine

- Speed match between the pump and turbine no longer a concern

- Easier to control the pump speed, and hence where the pump operates

- Eliminates large temperature gradients between the hot turbine and cold pump

- Simplifies the engine

- At current battery energy/power density levels, e-pumps make sense for smaller engines (5-10K lbf thrust)

Concepts NREC has been active in the e-pump arena for 10 years with prior in-depth experience researching and developing conventional rocket turbopumps.

Below is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient.

Below is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient.

Here are some quotes from our Customer Satisfaction Survey sent out after every job:

- "Customer service is really good - they answer questions and concerns in a timely manner."

- "High performance from quote to delivery"

- "Concepts' decision to stock material that is qualified to our specifications is a great competitive advantage. Their willingness to provide technical / commercial informational support makes them my "go-to" supplier for milled impellers."

Agile Products Support (APS)

APS is Concepts NREC’s software maintenance and support program that elevates us from just a software provider to a valued partner.

An APS subscription is included with all annual licenses and is a highly-recommended option for perpetual software licenses. Every software customer is supported for one month following purchase for any installation questions that may arise. Learn more on the Agile Products Support Membership Benefits Datasheet.

- Free software updates

- One business day response times

- Expert technical assistance

- Major discounts on software workshops

- Discounted professional development course

- Annual balloting system for development planning

- Annual Meetings

Rocket Turbopump Forum

Receive exclusive access to view 9 hours of recorded discussion from industry experts, engineers and developers on the current state and future of turbomachinery design, manufacture, and testing of rocket turbopump components.