Concepts NREC is the benchmark on collaborating with the market they serve.

You folks show a true willingness to help your clients succeed so that we can all win together! Thank you so much.

Bob Syvinsky

Senior CNC Programmer,

Whitcraft

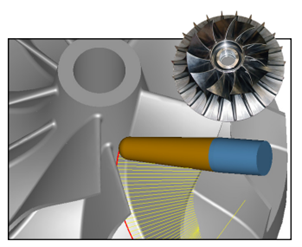

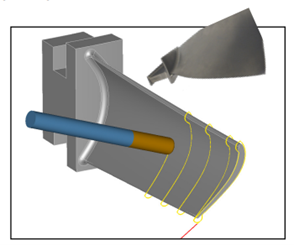

... we needed the best CAM software available.

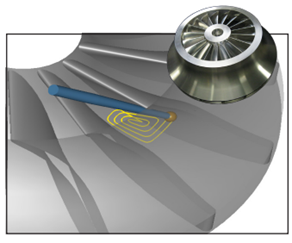

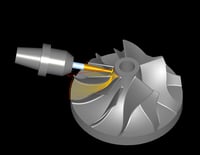

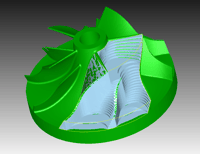

I noticed that blades were always better when produced with Concepts NREC software ... I was surprised at how intuitive it was.

... a lot of our customers were creating their blade geometry using Concepts NREC’s CAE software. This makes for a seamless transition to the CAM software helping to ensure the original design intent.

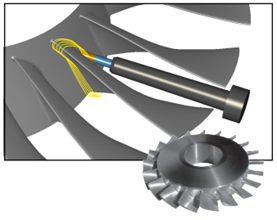

Here at Kinner Manufacturing, we think that MAX-PAC is the best solution to the unique challenges of 5-axis machining of bladed components.

Ray Kinner, Owner, Kinner Manufacturing

Gabrielle Francis

Product Designer, Google

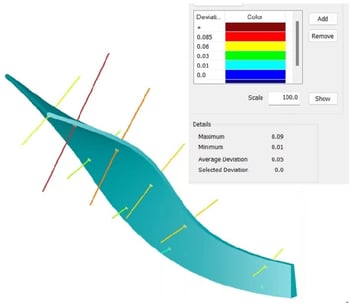

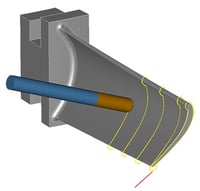

We often receive complex customer designs for turbomachinery manufacturing evaluations.

We trust the methodologies in MAX-PAC to quickly identify a robust working model for accurate and efficient toolpaths that meet our customer expectations.

Chris Davala, Principal Engineer

Denisse Atkinson

Product Designer, Google

I have found MAX-PAC by Concepts NREC to be an exceptionally powerful and yet easy to use CAM software for demonstrating our MAZAK 5-axis machines.

I needed something easy to learn yet powerful enough to make it look easy and MAX-PAC fit the bill perfectly.

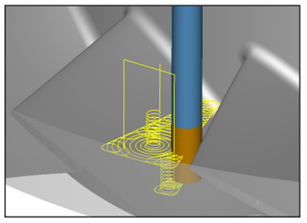

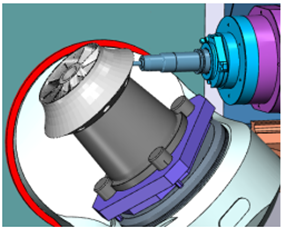

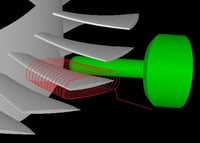

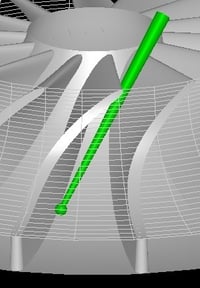

MAX-PAC does everything for me, it helps me spec the correct tool form, it provides optimized and easily adjustable 5-axis toolpaths for both rough and finish and it provides simulated toolpaths.

Robin Cave, Applications Engineer, Mazak Corporation

Justin Galloway

Product Designer, Google