MAX-AB™

Cutter Path Generation for 5-axis Point Milling of Turbomachinery Components

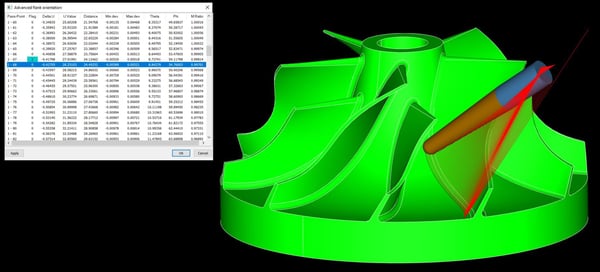

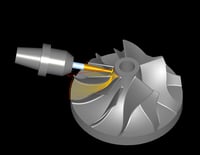

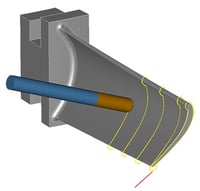

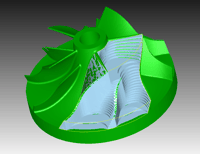

MAX-AB™ creates 5-axis CNC machining instructions for point milling of turbomachinery components with arbitrary (free-form) blade surfaces. Typical applications include axial compressors and turbines, pumps, compressors, turbochargers, radial-inflow turbines, and inducers.

-

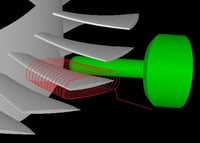

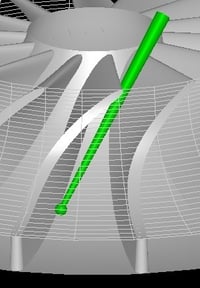

MAX-AB emphasizes smooth machining instructions that are compatible with high-speed milling applications. MAX-AB is generally applied to the class of components that are designed with arbitrary surfaces, but it can also be used with a high-speed milling process for ruled-surface components. MAX-AB is particularly suited to today’s CFD-influenced blade shapes that can be difficult or impossible to cut with other general CAM systems.

-

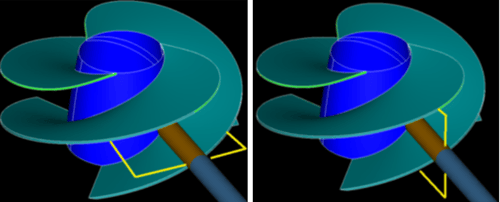

MAX-AB includes advanced capabilities for roughing, plunge milling, hub finish, point-milled blade finish, leading edge, fillet finish, and tip milling.

MAX-AB emphasizes smooth machining instructions that are compatible with high-speed milling applications. MAX-AB is generally applied to the class of components that are designed with arbitrary surfaces, but it can also be used with a high-speed milling process for ruled-surface components. MAX-AB is particularly suited to today’s CFD-influenced blade shapes that can be difficult or impossible to cut with other general CAM systems.

MAX-AB includes advanced capabilities for roughing, plunge milling, hub finish, point-milled blade finish, leading edge, fillet finish, and tip milling.

MAX-AB™ Advantages

MAX-AB™ emphasizes smooth machining instructions that are compatible with high-speed milling applications. MAX-AB™ is generally applied to the class of components that are designed with arbitrary surfaces, but it can also be used with a high-speed milling process for ruled-surface components. MAX-AB™ is particularly suited to today’s CFD-influenced blade shapes that can be difficult or impossible to cut with other general CAM systems.

MAX-AB™ includes advanced capabilities for roughing, plunge milling, hub finish, point-milled blade finish, leading edge, fillet finish, and tip milling.

MAX-AB Advantages

MAX-AB emphasizes smooth machining instructions that are compatible with high-speed milling applications. MAX-AB is generally applied to the class of components that are designed with arbitrary surfaces, but it can also be used with a high-speed milling process for ruled-surface components. MAX-AB is particularly suited to today’s CFD-influenced blade shapes that can be difficult or impossible to cut with other general CAM systems.

Advanced Capabilities

MAX-AB includes advanced capabilities for roughing, plunge milling, hub finish, point-milled blade finish, leading edge, fillet finish, and tip milling.

Software Highlights

2020 Release Features

MAX-PAC Add-On Modules

MAX-PAC Add-On Modules

Software Support

Customer-driven Improvement

Technical Support

Documentation

Other MAX-PAC™ Add-On Modules

Select any combination to meet your specific machining requirements.

Find Your Rep

North America

Mr. Don Roberson

Phone:

Email: DRoberson@conceptsnrec.com

South America

Time is money. Save more of it.

Sprocket Rocket Theme helps you save countless hours by making sweeping charges across your entire site instantly.

EMEA

Responsive by nature and packed with SEO performance.

Creating mobile-friendly pages that load quickly and adhere to Google Core Web Vitals isn't just about getting a fast page speed score. It's great for your website visitors, too.

Sprocket Rocket Theme is lightweight and built to perform for desktop, tablet, and mobile device visitors.

Russia

Easy and fast adjustments of elements is possible with Core template. Find our more about our all-in-one programmatic template.

Great China & SE Asia

Easy and fast adjustments of elements is possible with Core template. Find our more about our all-in-one programmatic template.

India

Easy and fast adjustments of elements is possible with Core template. Find our more about our all-in-one programmatic template.

Japan

Easy and fast adjustments of elements is possible with Core template. Find our more about our all-in-one programmatic template.

South Korea

Easy and fast adjustments of elements is possible with Core template. Find our more about our all-in-one programmatic template.

CAM Software Workshops

2021 November CAM Software Workshop

Application-Based Learning

Date: October 18 - 29, 2021

Time: 9:30 am - 1:00 pm EDT

Course Fee: $3500 USD

This course is designed to help engineers design, test, and run pumps and systems that are more efficient, more economical, and more reliable. Engineers will come to understand the best state-of-the-art design practices and learn the latest theories on performance, cavitation, dynamic forces, and noise. The course will review the latest advances in design tools and will provide expert and relevant instruction to designers on pump design optimization. Nearly half of all the teaching is focused on actual commercial design cases with measured data for confirmation.

2021 Trade Show: ComVac Asia

Visit Concepts NREC China at the ComVac Asia

Date: October 26-29, 2021

Location: Shanghai, China

To learn more, visit https://www.comvac-asia.com/index.php?lang=en

Find Your Rep

Corporate Headquarters

217 Billings Farm Road

White River Junction, VT 05001-9486

Phone: 802-296-2321

Fax: 802-296-2325

Email: sales@conceptsnrec.com

North America Software Sales

Phone: 802-280-6181

Fax: 802-296-2325

Email: droberson@conceptsnrec.com

" Kinner Manufacturing was founded in 2007 with the goal to deliver the highest-quality bladed parts to our customers. To deliver on that goal, we needed the best CAM software available. As a machinist, I had worked with many CAM systems. I noticed that blades were always better when produced with Concepts NREC software, so we called them to set up a demo. Having never actually used the software to create a design, I was surprised at how intuitive it was. We decided to go with MAX-PAC™ and we were trained and creating programs right away.

As we grew, we noticed that a lot of our customers were creating their blade geometry using Concepts NREC’s CAE software. This makes for a seamless transition to the CAM software helping to ensure the original design intent. Having a suite of software that spans the whole process eliminates some of the issues that can happen when designs are switched between different programs.

Here at Kinner Manufacturing, we think that MAX-PAC is the best solution to the unique challenges of 5-axis machining of bladed components."

Ray Kinner, Owner