Turbomachinery Software Solutions

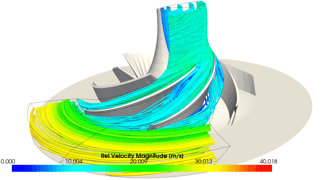

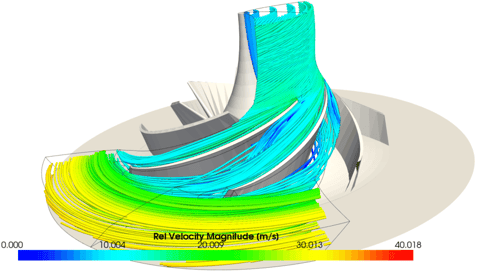

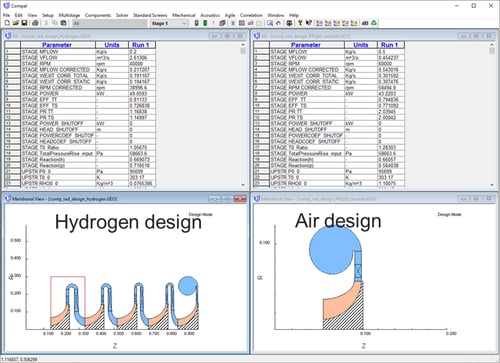

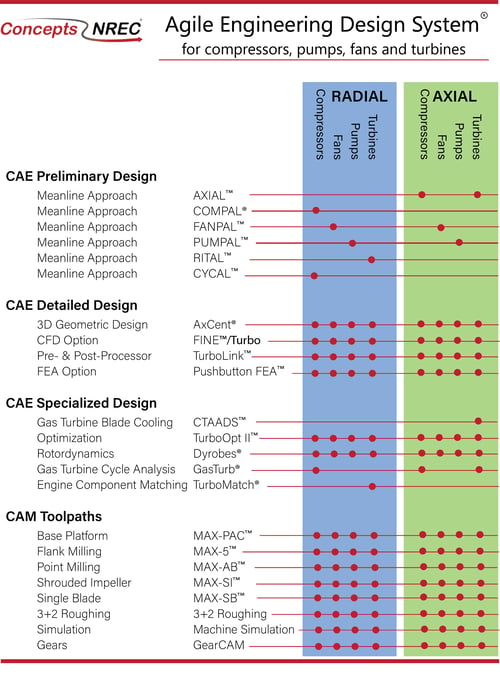

Concepts NREC provides an “art to part” software tool chain that enables every step in the turbomachinery development workflow.

Our design software solutions empower users with full creative control over the “art” of turbomachinery design. These solutions provide an agile interface for 1D and 3D conceptual design and integrated analysis tools to verify performance and durability. We also provide optimization solutions that work in conjunction with our products to expand the design space to make the probable possible.

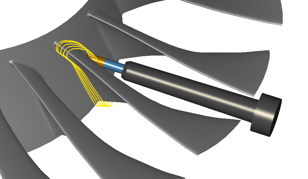

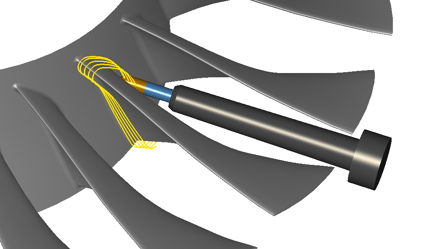

For those looking to make their concept a hardware reality, our machining software solutions can be utilized to generate the most accurate and efficient tool path for the “part”. The vertical integration of these solutions with the rest of the Agile product suite allows the user to go from digital to physical while simultaneously minimizing overall design time, optimizing the manufacturing process, and achieving superior performance.

Regardless of what type of turbomachine you are creating, we have a solution catered to overcoming its unique challenges.

Proven Expertise

Agile Products Support (APS)

APS is Concepts NREC’s software maintenance and support program that elevates us from just a software provider to a valued partner.

An APS subscription is included with all annual licenses and is a highly-recommended option for perpetual software licenses. Every software customer is supported for one month following purchase for any installation questions that may arise. Learn more on the Agile Products Support Membership Benefits Datasheet.

- Free software updates

- One business day response times

- Expert technical assistance

- 24/7 Feedback

- Annual Meetings

- Discounted professional development course

Software Brochure

Our integrated design and manufacturing software tools provide designers with a cost-effective, concurrent development approach that balances issues of performance, reliability, cost-effectiveness, and manufacturability.

Contact Us

North America

Mr. Don Roberson

Concepts NREC

Phone: 802-280-6181

Fax: 802-296-2325

Email: droberson@conceptsnrec.com

Latin America, India & SE Asia

Dr. David Schowalter

Concepts NREC

Phone: 781-937-4626

Fax: 802-296-2325

Email: dschowalter@conceptsnrec.com

EMEA

Greater China

Mr. Peng Wang

Concepts NREC

Mobile: +86 186 1128 2696

Email: pwang@conceptsnrec.com

South Korea

Dr. Hoyoun Kim

KIMHUA Technologies, Inc.

Phone: 82-02-556-1257

Fax: 82-02-556-4020

Email: hykim@kimhua.co.kr

Japan

Mr. Motonari Takahashi

Daiichi System Engineering (DSE)

Phone: 81-52-857-1715

Fax: 81-52-857-1711

E-mail: sales-CN@dse-corp.co.jp