Turbocharger Design

Design Solution for Turbochargers

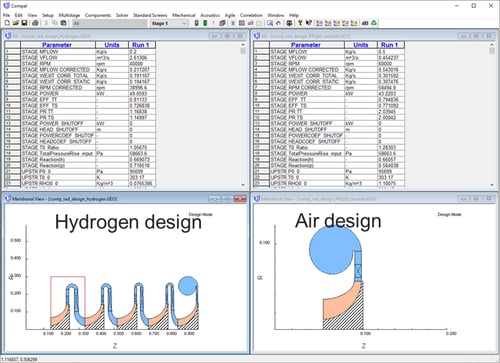

The Concepts NREC FINE/Agile for Turbochargers bundle delivers an integrated tool chain for the entire component design workflow of turbochargers. Starting with a wizard-based 1D design and analysis in COMPALTM and RITALTM (or AXIALTM), the designer will be quickly guided to a flow path that meets their specifications. This will result in a machine that has appropriate sizing, initial performance predictions, and even a preliminary matching of the turbine to the compressor if TurboMatch is added to the bundle. From there, more detailed analysis may be employed to ascertain the feasibility of the turbocharger by leveraging such tools as multi-point analysis to create performance maps for both hot and cold sides.

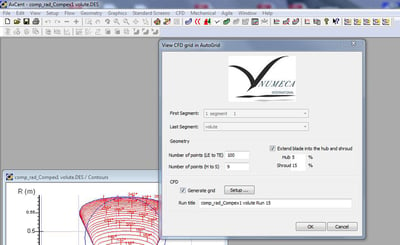

The Agile link is used to seamlessly transfer all data from COMPALTM and RITALTM (or AXIALTM) to our flagship 3D design product AxCentTM. This is where the designer can refine the design of each component by modifying distributions such as beta angle, lean, blade thickness, and many other geometric design parameters accompanied by real time updates of the 3D geometry. These changes can be moved forward into 3D CFD preparation or the Agile link may be used to return to COMPALTM and RITALTM (or AXIALTM) and determine the impact of the 3D geometry parameterization on the 1D analysis.

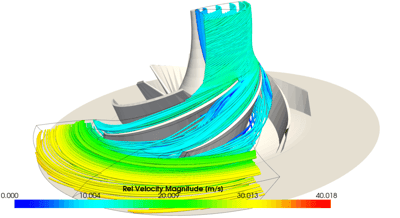

All pre-processing for 3D CFD is completed using pbPostTM. Here, the designer can provide all grid parameters, loads, and boundary conditions with the convenience of never leaving the AxCentTM interface. The fully prepared analysis is then initiated, while still in the AxCentTM interface, and all numerical calculations are completed using Cadence OMNIS/Turbo CFD. Upon completion, the results of the numerical solution are returned to pbPostTM and all turbomachinery-specific post-processing is completed within the AxCentTM interface.

The Concepts NREC FINE/Agile for Turbochargers truly provides all the tools required to meet the needs at the core of designing turbochargers.

Design Software Solution for Turbochargers

The Concepts NREC FINE/Agile for Turbochargers bundle delivers an integrated tool chain for the entire component design workflow of turbochargers. Starting with a wizard-based 1D design and analysis in COMPAL® and RITAL™ (or AXIAL™), the designer will be quickly guided to a flow path that meets their specifications. This will result in a machine that has appropriate sizing, initial performance predictions, and even a preliminary matching of the turbine to the compressor if TurboMatch is added to the bundle. From there, more detailed analysis may be employed to ascertain the feasibility of the turbocharger by leveraging such tools as multi-point analysis to create performance maps for both hot and cold sides.

The Agile link is used to seamlessly transfer all data from COMPAL® and RITAL™ (or AXIAL™) to our flagship 3D design product AxCent®. This is where the designer can refine the design of each component by modifying distributions such as beta angle, lean, blade thickness, and many other geometric design parameters accompanied by real time updates of the 3D geometry. These changes can be moved forward into 3D CFD preparation or the Agile link may be used to return to COMPAL® and RITAL™ (or AXIAL™) and determine the impact of the 3D geometry parameterization on the 1D analysis.

All pre-processing for 3D CFD is completed using TurboLink™. Here, the designer can provide all grid parameters, loads, and boundary conditions with the convenience of never leaving the AxCent® interface. The fully prepared analysis is then initiated, while still in the AxCent® interface, and all numerical calculations are completed using Cadence OMNIS/Turbo CFD. Upon completion, the results of the numerical solution are returned to TurboLink™ and all turbomachinery-specific post-processing is completed within the AxCent® interface.

The Concepts NREC FINE/Agile for Turbochargers truly provides all the tools required to meet the needs at the core of designing turbochargers.

Agile Products Support (APS)

APS is Concepts NREC’s software maintenance and support program that elevates us from just a software provider to a valued partner.

An APS subscription is included with all annual licenses and is a highly-recommended option for perpetual software licenses. Every software customer is supported for one month following purchase for any installation questions that may arise. Learn more on the Agile Products Support Membership Benefits Datasheet.

- Free software updates

- One business day response times

- Expert technical assistance

- Major discounts on software workshops

- Discounted professional development course

- Annual balloting system for development planning

- Annual Meetings