TurboLink™

Intuitive CFD Post Processing Software

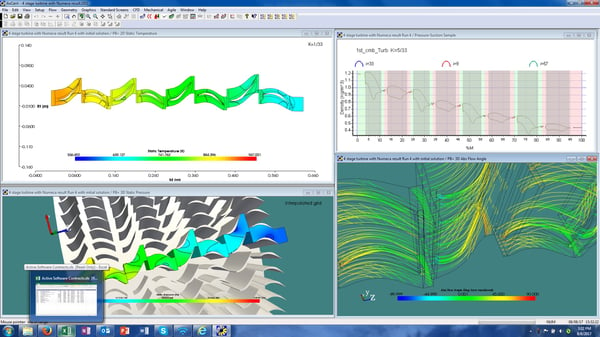

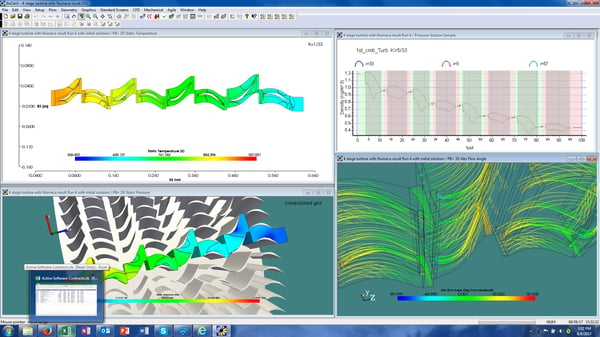

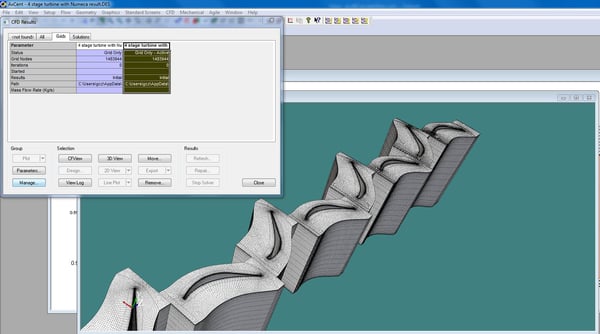

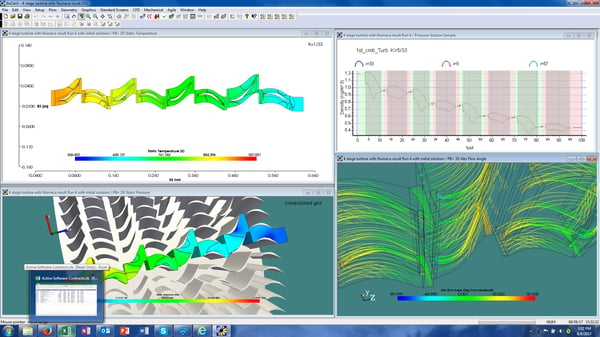

Concepts NREC’s TurboLink™ product was created to provide designers a turbomachinery-specific pre- and post-processing tool to link our flagship 3D design product, AxCent®, and our partner Cadence/NUMECA’s FINE™ CFD products.

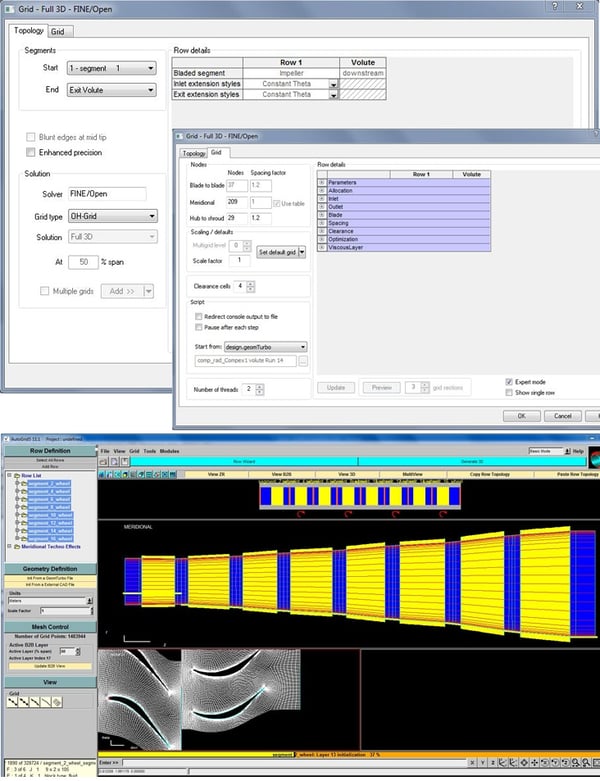

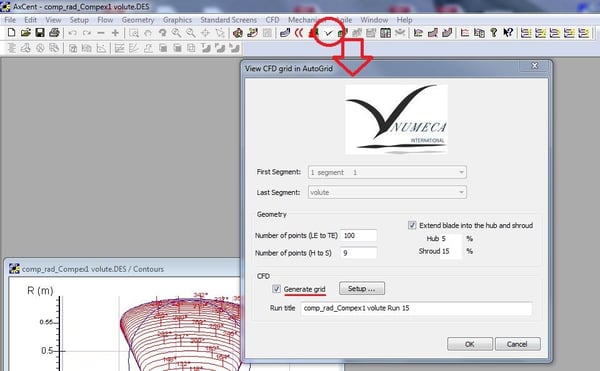

Recent new developments allow for the repaired unstructured volute grid to be imported back into the AxCent® software. This feature will allow a designer to complete more design studies on the rotor and stator design while holding that volute design constant, providing a more accurate simulation, a better understanding of the full stage performance, and the ability to drive critical design selections for all components to ensure design requirements are achieved.

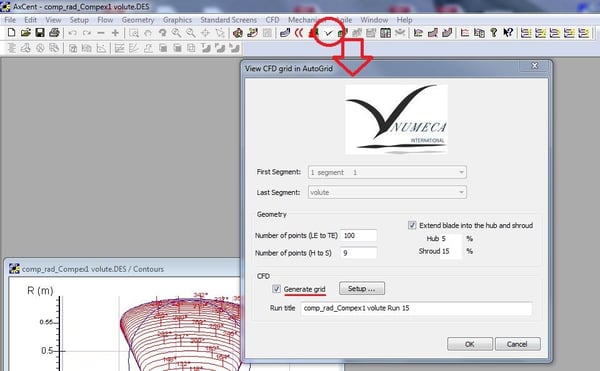

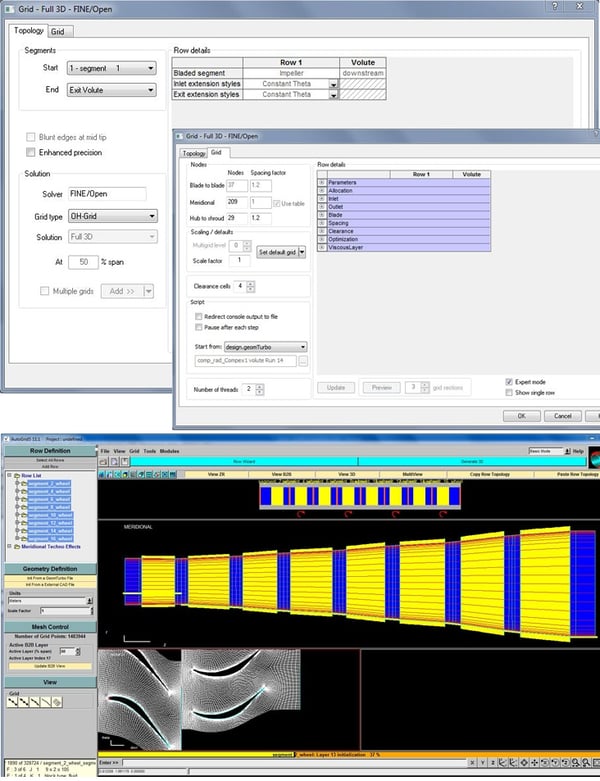

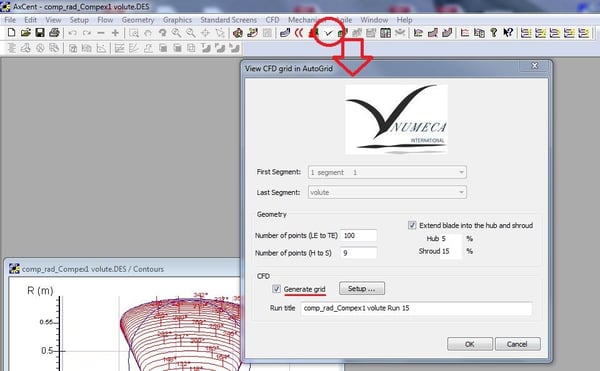

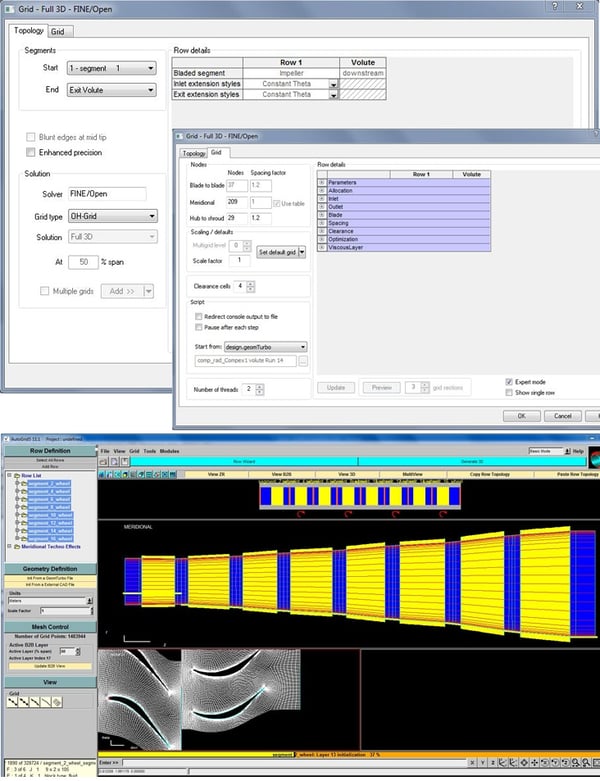

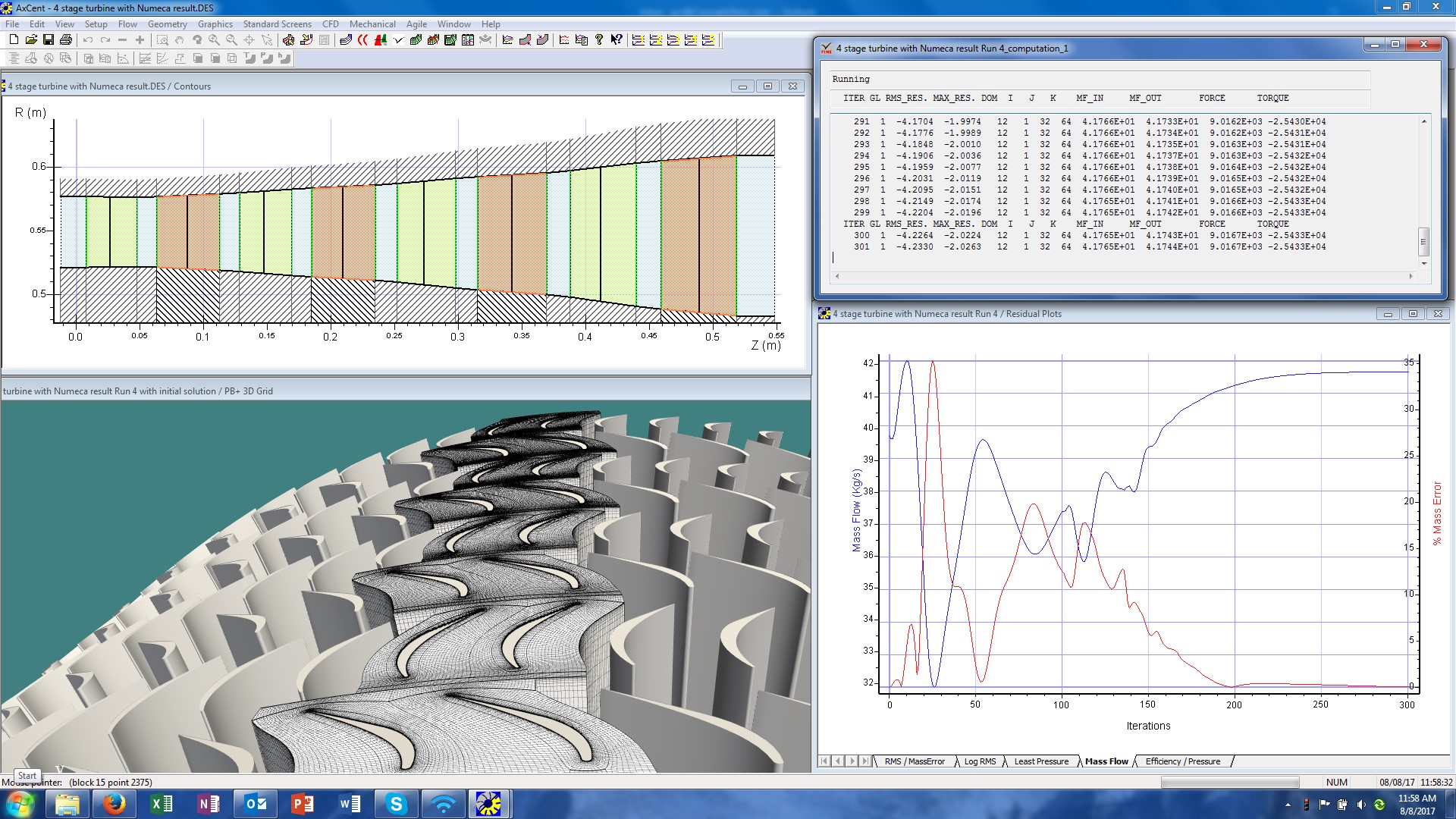

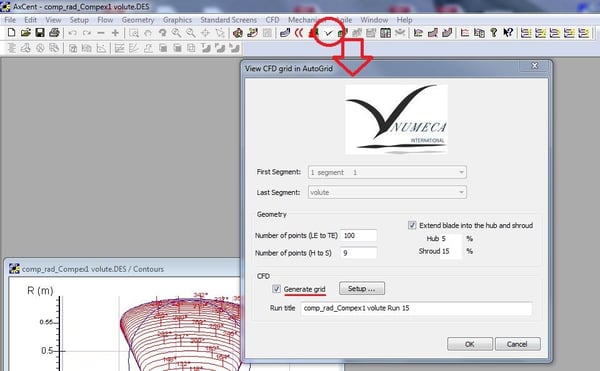

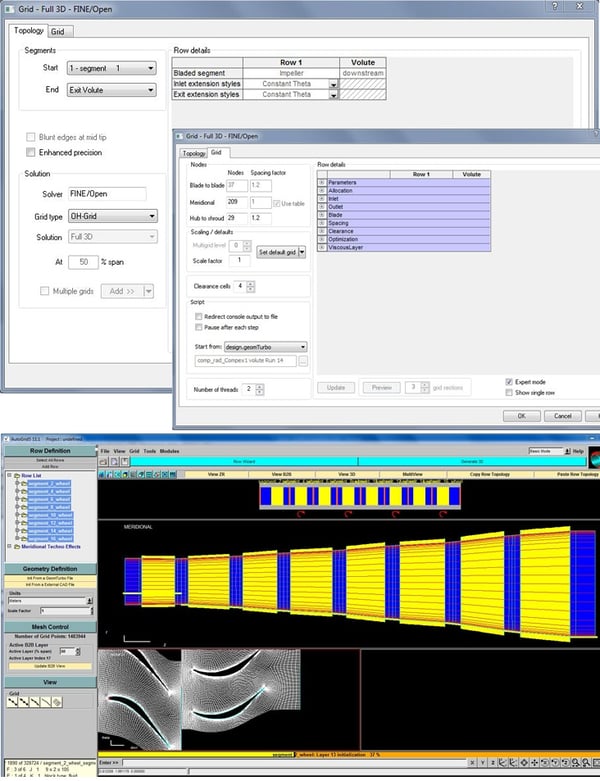

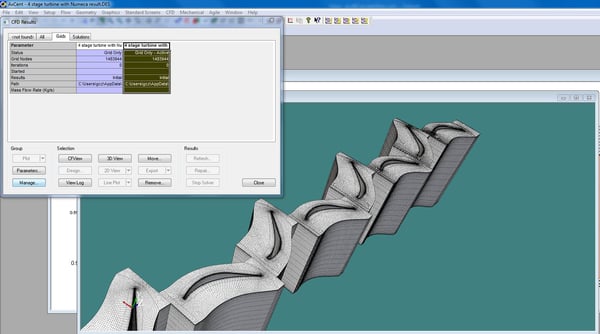

Concepts NREC's TurboLink™ is a pushbutton postprocessing module that enables Cadence/NUMECA’s FINE™/Turbo to be launched from within the AxCent® environment.

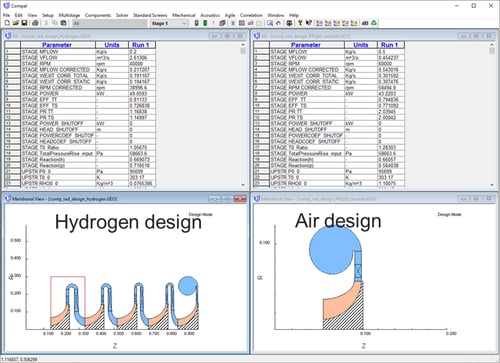

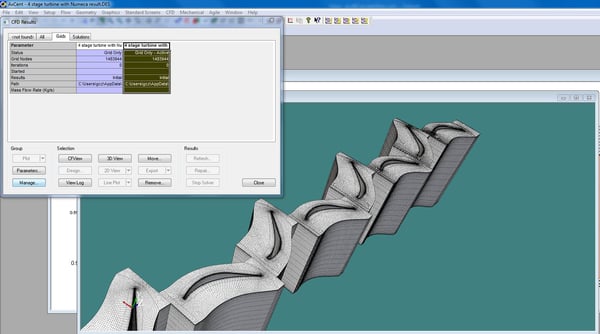

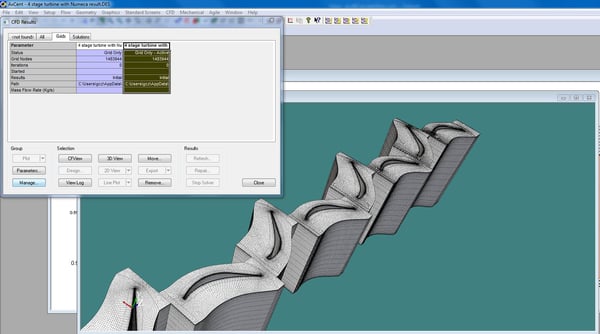

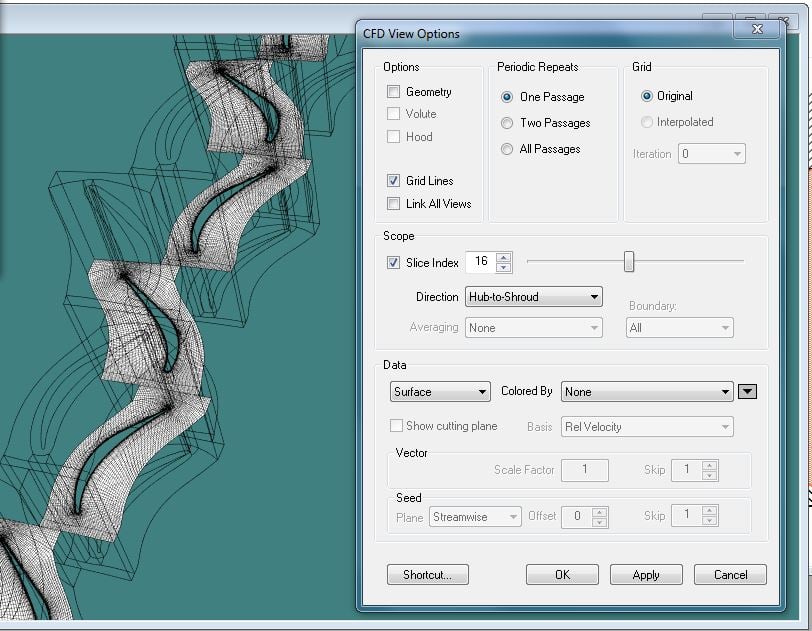

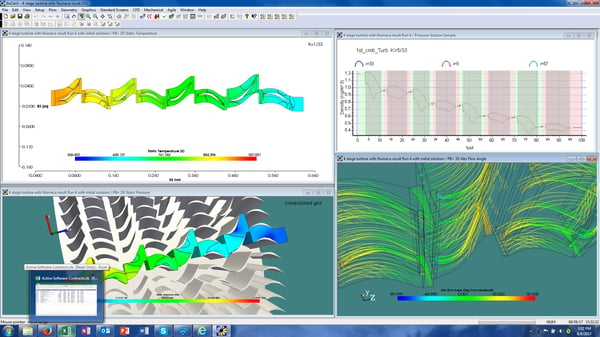

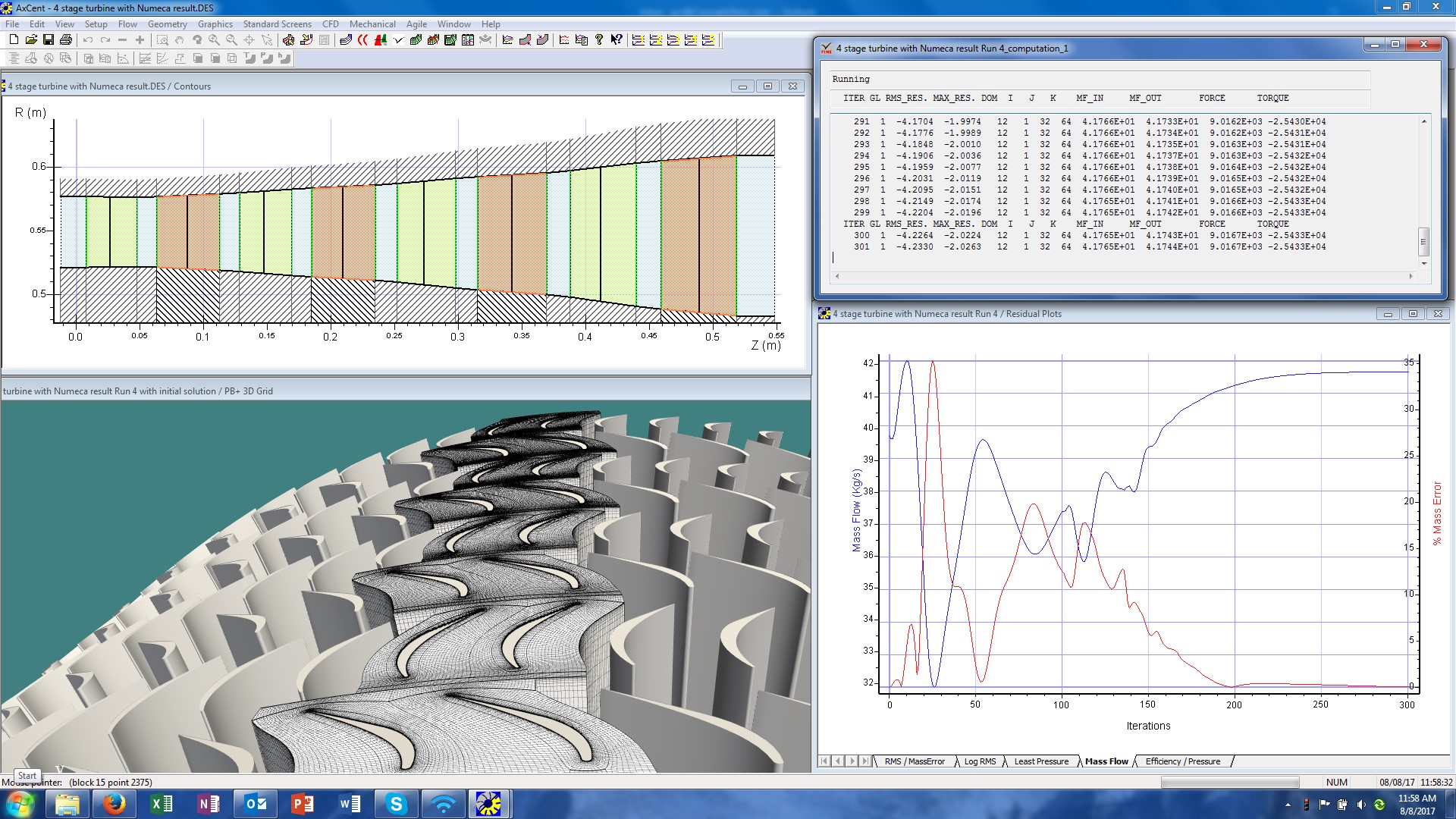

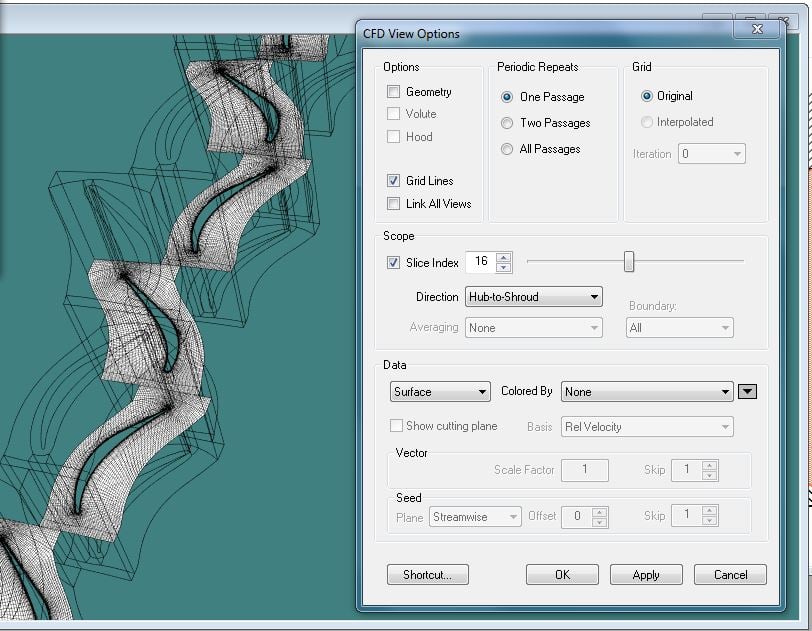

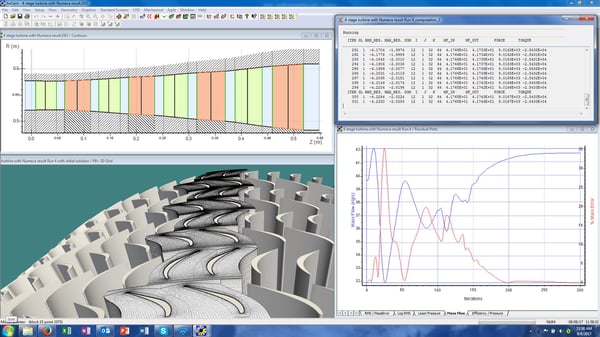

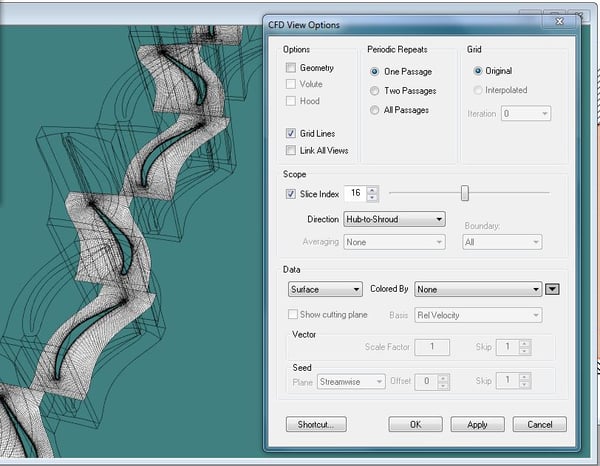

It can also import the CFD results generated by FINE™/Turbo back into the AxCent® viewing environment.

For current Cadence/NUMECA users, TurboLink™ offers an easily configured alternative to their current postprocessing experience that eliminates the step of loading geometry. For current Pushbutton CFD users, TurboLink™ offers a familiar way to view and manipulate CFD results from FINE™/Turbo.

Optimized for a Turbomachinery Designer

TurboLink™ saves designers the time they might spend loading geometry, applying boundary conditions, gridding and configuring solvers inside a second interface. It just requires a click of a mouse.

Bringing the FINE™/Turbo results back into AxCent® delivers a designer-centric view of the analysis that doesn't require any navigation. The tools are familiar and intuitive and focused on what turbomachinery designers need.

Outcome of a Strong Partnership

The TurboLink™ module is part of the long-term vision that Cadence/NUMECA and Concepts NREC share to bring together the best-in-class turbomachinery design tools and the fastest and most accurate CFD suite. By combining the best capabilities of both companies, customers will have access to the most advanced suite of turbomachinery software available. Our integrated solution spans preliminary design through detailed 3D steady and unsteady CFD analysis.

To learn more about FINE™/Turbo, visit Cadence/NUMECA's website.

Introduction to pbPost

Introduction to pbPost

-

Concepts NREC's pbPost™ is a pushbutton postprocessing module that enables Cadence/NUMECA’s FINE™/Turbo to be launched from within the AxCent® environment.

-

It can also import the CFD results generated by FINE™/Turbo back into the AxCent® viewing environment.

-

For current Cadence/NUMECA users, pbPost™ offers an easily configured alternative to their current postprocessing experience that eliminates the step of loading geometry. For current Pushbutton CFD users, pbPost™ offers a familiar way to view and manipulate CFD results from FINE™/Turbo.

-

pbPost™ saves designers the time they might spend loading geometry, applying boundary conditions, gridding and configuring solvers inside a second interface. It just requires a click of a mouse.

Bringing the FINE™/Turbo results back into AxCent® delivers a designer-centric view of the analysis that doesn't require any navigation. The tools are familiar and intuitive and focused on what turbomachinery designers need.

-

The pbPost™ module is part of the long-term vision that Cadence/NUMECA and Concepts NREC share to bring together the best-in-class turbomachinery design tools and the fastest and most accurate CFD suite. By combining the best capabilities of both companies, customers will have access to the most advanced suite of turbomachinery software available. Our integrated solution spans preliminary design through detailed 3D steady and unsteady CFD analysis.

Concepts NREC's pbPost™ is a pushbutton postprocessing module that enables Cadence/NUMECA’s FINE™/Turbo to be launched from within the AxCent® environment.

It can also import the CFD results generated by FINE™/Turbo back into the AxCent® viewing environment.

For current Cadence/NUMECA users, pbPost™ offers an easily configured alternative to their current postprocessing experience that eliminates the step of loading geometry. For current Pushbutton CFD users, pbPost™ offers a familiar way to view and manipulate CFD results from FINE™/Turbo.

pbPost™ saves designers the time they might spend loading geometry, applying boundary conditions, gridding and configuring solvers inside a second interface. It just requires a click of a mouse.

Bringing the FINE™/Turbo results back into AxCent® delivers a designer-centric view of the analysis that doesn't require any navigation. The tools are familiar and intuitive and focused on what turbomachinery designers need.

The pbPost™ module is part of the long-term vision that Cadence/NUMECA and Concepts NREC share to bring together the best-in-class turbomachinery design tools and the fastest and most accurate CFD suite. By combining the best capabilities of both companies, customers will have access to the most advanced suite of turbomachinery software available. Our integrated solution spans preliminary design through detailed 3D steady and unsteady CFD analysis.

Launch FINE™/Turbo from within the AxCent®

Concepts NREC's pbPost™ is a pushbutton postprocessing module that enables Cadence/NUMECA’s FINE™/Turbo to be launched from within the AxCent® environment.

Import FINE™/Turbo CFD results back into AxCent®

It can also import the CFD results generated by FINE™/Turbo back into the AxCent® viewing environment.

Easily Configured Postprocessing Experience

For current Cadence/NUMECA users, pbPost™ offers an easily configured alternative to their current postprocessing experience that eliminates the step of loading geometry. For current Pushbutton CFD users, pbPost™ offers a familiar way to view and manipulate CFD results from FINE™/Turbo.

Optimized for a Turbomachinery Designer

pbPost™ saves designers the time they might spend loading geometry, applying boundary conditions, gridding and configuring solvers inside a second interface. It just requires a click of a mouse.

Bringing the FINE™/Turbo results back into AxCent® delivers a designer-centric view of the analysis that doesn't require any navigation. The tools are familiar and intuitive and focused on what turbomachinery designers need.

Outcome of a Strong Partnership

The pbPost™ module is part of the long-term vision that Cadence/NUMECA and Concepts NREC share to bring together the best-in-class turbomachinery design tools and the fastest and most accurate CFD suite. By combining the best capabilities of both companies, customers will have access to the most advanced suite of turbomachinery software available. Our integrated solution spans preliminary design through detailed 3D steady and unsteady CFD analysis.

Product Support

Customer-driven Improvement

Technical Support

Documentation

Data Sheet

Detailed 3D Design and Rapid 2D Flow Analysis Module for Turbomachinery

Find Your Rep

Our Sales Offices are strategically located around the globe to service all your turbomachinery needs.

Corporate Headquarters

217 Billings Farm Road

White River Junction, VT 05001-9486

Phone: 802-296-2321

Fax: 802-296-2325

Email: sales@conceptsnrec.com

North America Software Sales

Phone: 802-280-6181

Fax: 802-296-2325

Email: droberson@conceptsnrec.com

Upcoming Events

Tradeshows, Workshops, Webinars and more.

2021 Online Centrifugal and Axial Pumps Course - Modern Design, Performance, and Problem Solving

Application-Based Learning

Date: October 18 - 29, 2021

Time: 9:30 am - 1:00 pm EDT

Course Fee: $3500 USD

This course is designed to help engineers design, test, and run pumps and systems that are more efficient, more economical, and more reliable. Engineers will come to understand the best state-of-the-art design practices and learn the latest theories on performance, cavitation, dynamic forces, and noise. The course will review the latest advances in design tools and will provide expert and relevant instruction to designers on pump design optimization. Nearly half of all the teaching is focused on actual commercial design cases with measured data for confirmation.

2021 Trade Show: ComVac Asia

Visit Concepts NREC China at the ComVac Asia

Date: October 26-29, 2021

Location: Shanghai, China

To learn more, visit https://www.comvac-asia.com/index.php?lang=en

I came to the realization that we needed some objective insight.

We were working well with the OEM but even with our combined efforts, we were struggling to get a critical compressor to pass performance on their test stand. Although I'd never directly done business with Concepts NREC I was familiar with them and their capability so I chose to contact them when I came to the realization that we needed some objective insight. Concepts NREC fielded my cold call and immediately engaged their expertise in a complex problem that was also challenged by schedule constraints. They provided increased understanding of an already complex CFD which resulted in increased confidence that the proposed solution would succeed on the next test stand attempt (which it did!). We are pleased to have had the help of Concepts NREC and now have a well-performing compressor in our process.”

Bryan Barrington

Senior Advisor - Machinery Engineering