AxCent®

AxCent® is used for detailed 3D geometric design and for rapid flow analysis of multistaged axial and radial turbomachinery through streamline curvature. AxCent employs powerful features for axial, mixed-flow, and radial geometries that can be combined to design almost any turbomachinery.

Blade Geometry

AxCent easily handles the most complex blade geometry. A partial list of blade design features include:

- Blade stacking of 2D cross sections

- Blade restaggering around an arbitrary axis

- Bowed blading defined by hub-to-shroud bow profiles

- Bowed or sculpted element with arbitrary number of mid-span sections

- Variable tip clearance on either end of the blade

- Flow cuts and radial trims

- Swept leading/trailing edges

- Multiple, offset, and independent splitter blades

- Irregular blade/splitter configurations for noise reduction

Other design features include:

- Parameterized volute geometry generation

- Split duct geometry

- Fillets with constant or variable radius and aspect ratio

Recent 3D features include:

- Cutaway view allows real-time cross sections to be viewed as the design is edited

- 3D overlays permit viewing of current, real-time changes on a transparent overlay

Flow analysis

AxCent includes several options for real-time interactive flow analysis:

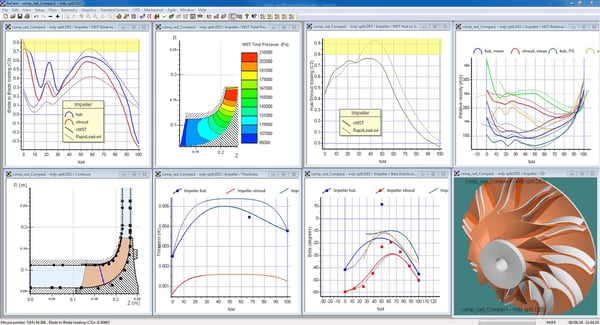

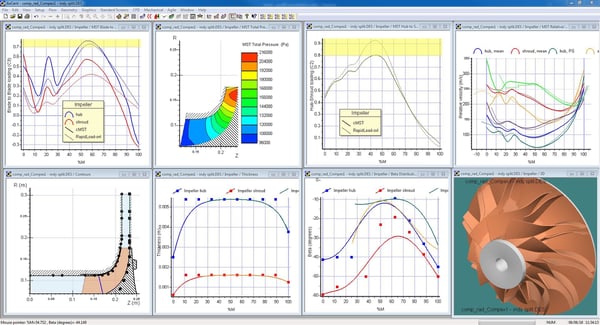

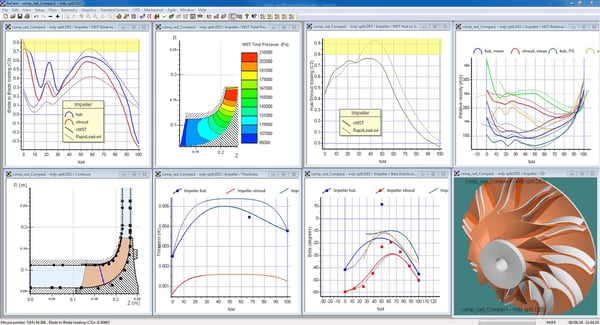

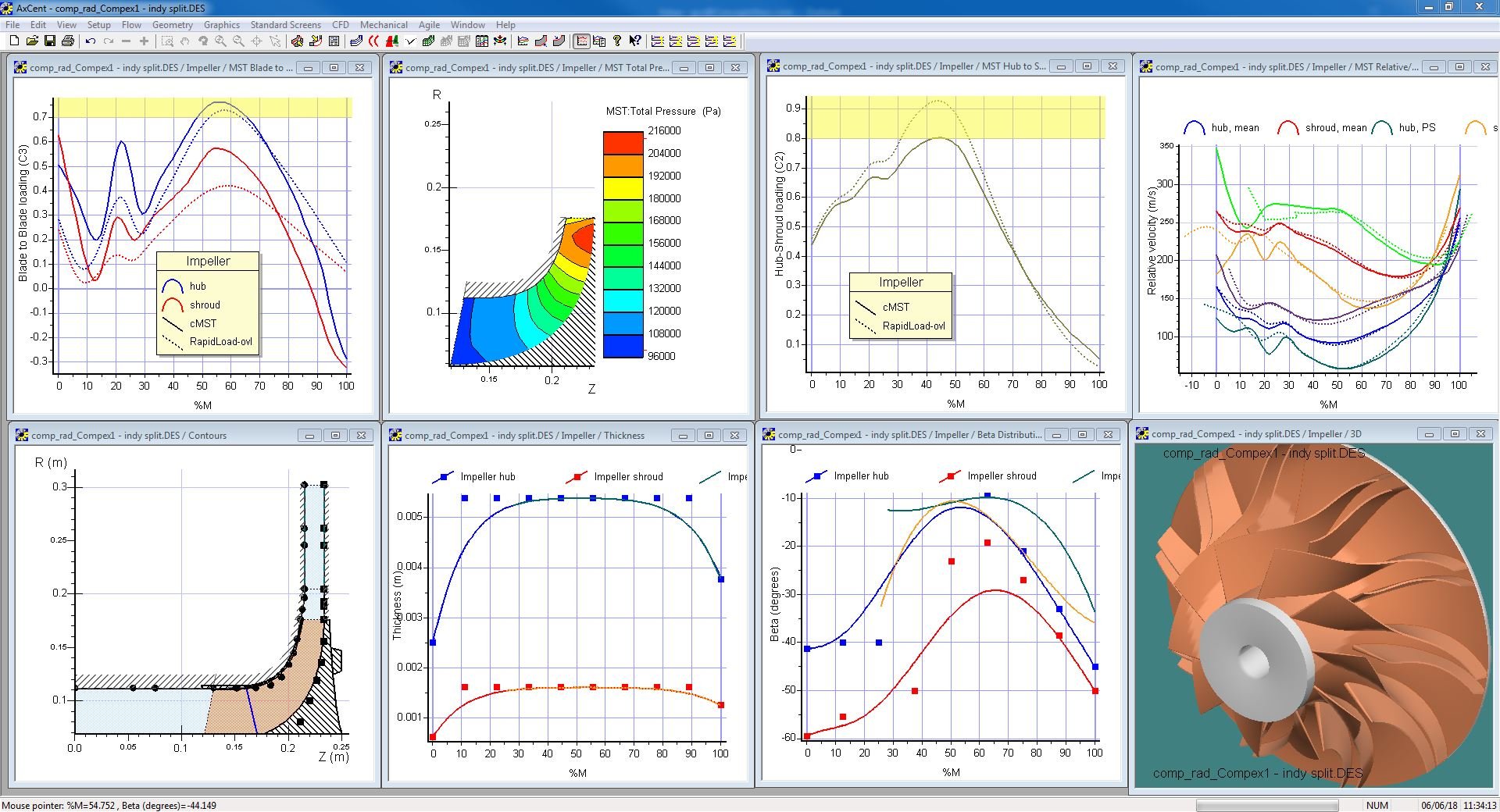

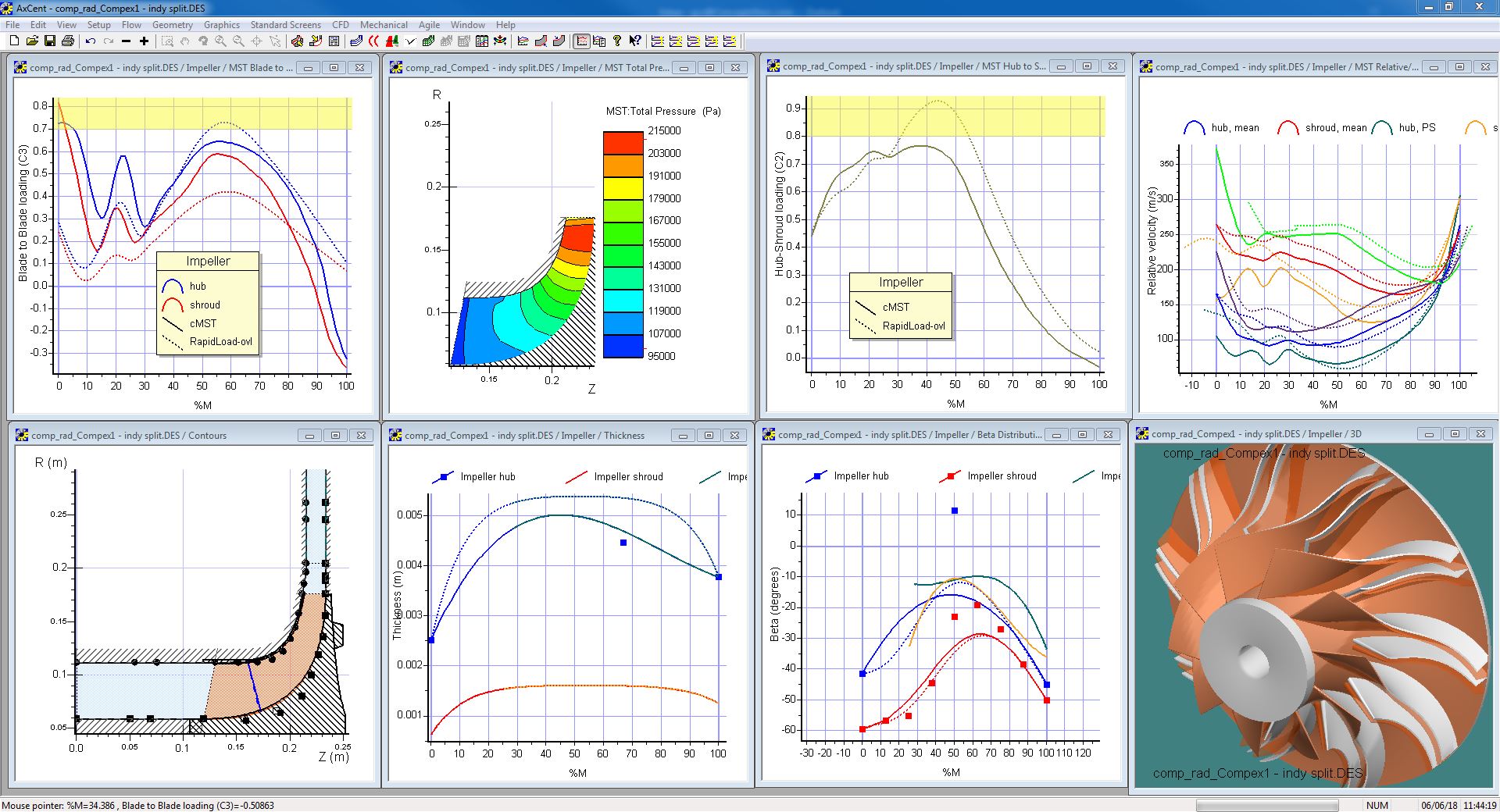

- Inviscid streamline curvature solvers, including Concepts NREC's Multi-Stream Tube Solver (MST), are recognized in the industry as the best for centrifugal pumps and compressors

- MST puts the power of real-time analysis in your hands. It enables you to immediately visualize the consequences of design changes on velocity, temperature, and pressure. You can look at multiple iterations in seconds, rather than the hours necessary to export each design to CAD for CFD analysis.

- Using MST, you can significantly reduce the overall design cycle time by providing an optimized iteration for validation, rather then the more traditional iterative process that requires a lot more back and forth.

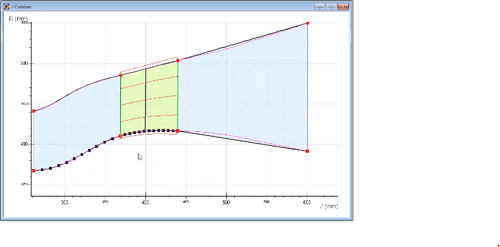

Design before editing

Design before editing

Design after editing

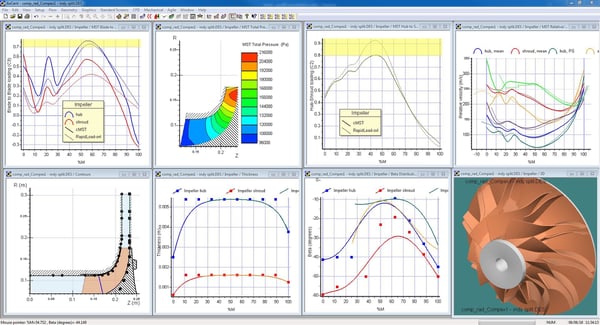

And a number of CFD-based solvers:

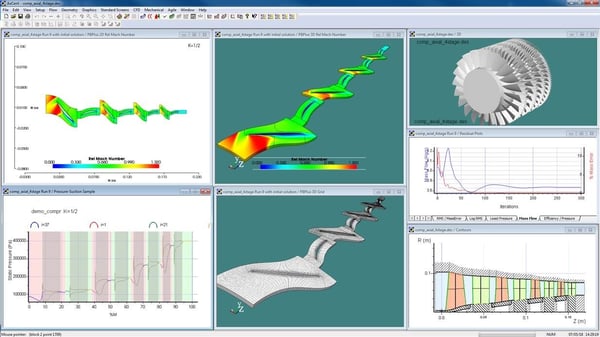

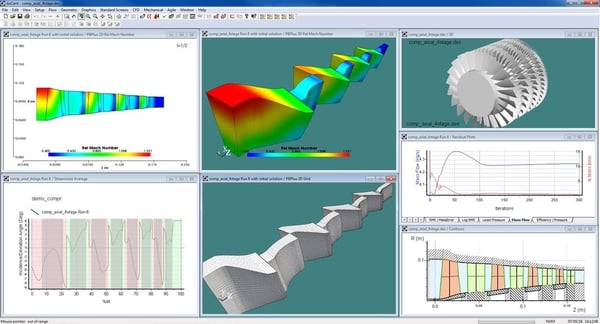

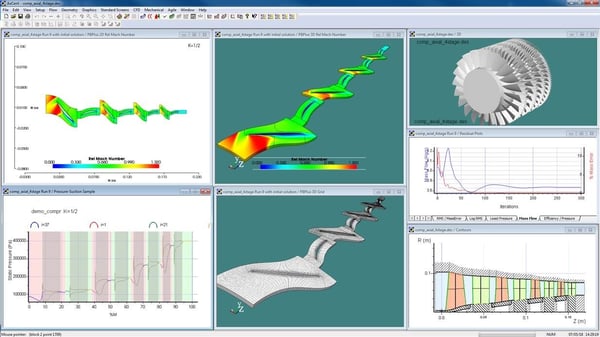

- Blade-to-blade is a powerful and rapid quasi-3D solver for quickly evaluating flow patterns across the channel

- Quickly provides validated feedback to resolve blade profiles for twist, camber and thickness

- Throughflow is another quasi-3D solver for rapid analysis of axial streamwise flow in compressors and turbines using industry-standard loss and deviation models

- Enables feedback in minutes compared to full CFD analysis

- Run multiple iterations to improve performance

- Full 3D CFD with an advanced full Navier-Stokes solver for comprehensive analysis using a seamless one-click interface with Cadence/NUMECA's FINE®/Turbo

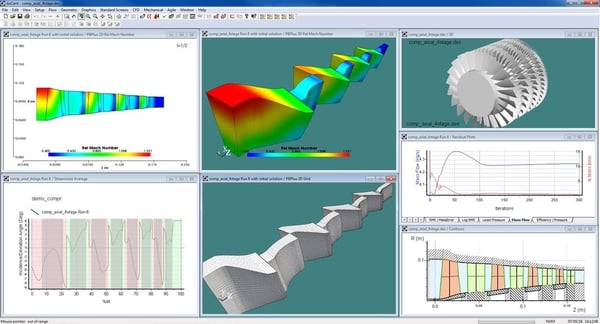

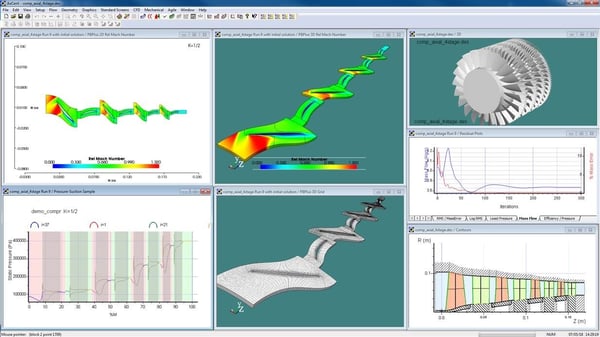

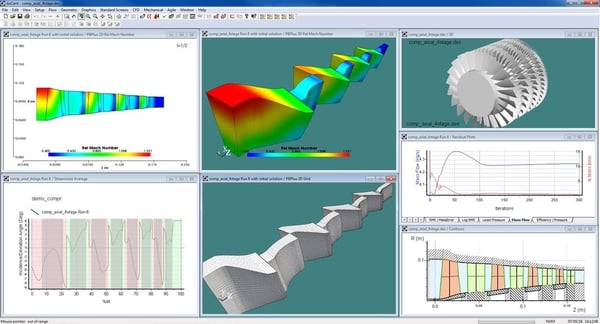

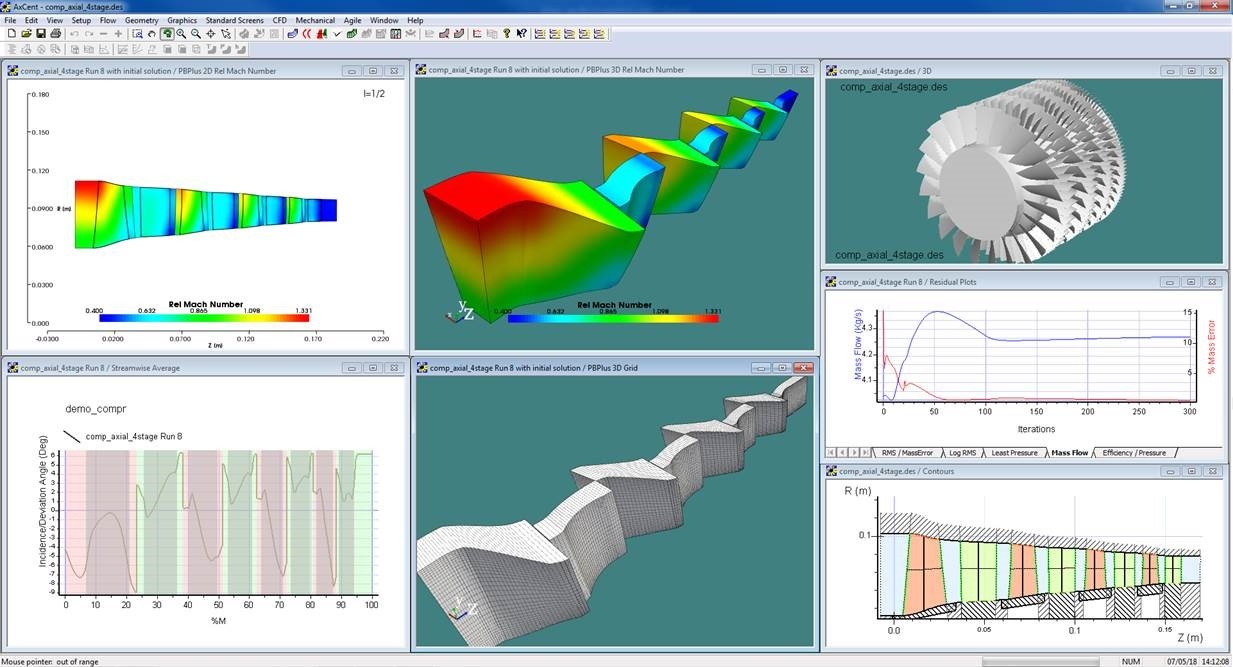

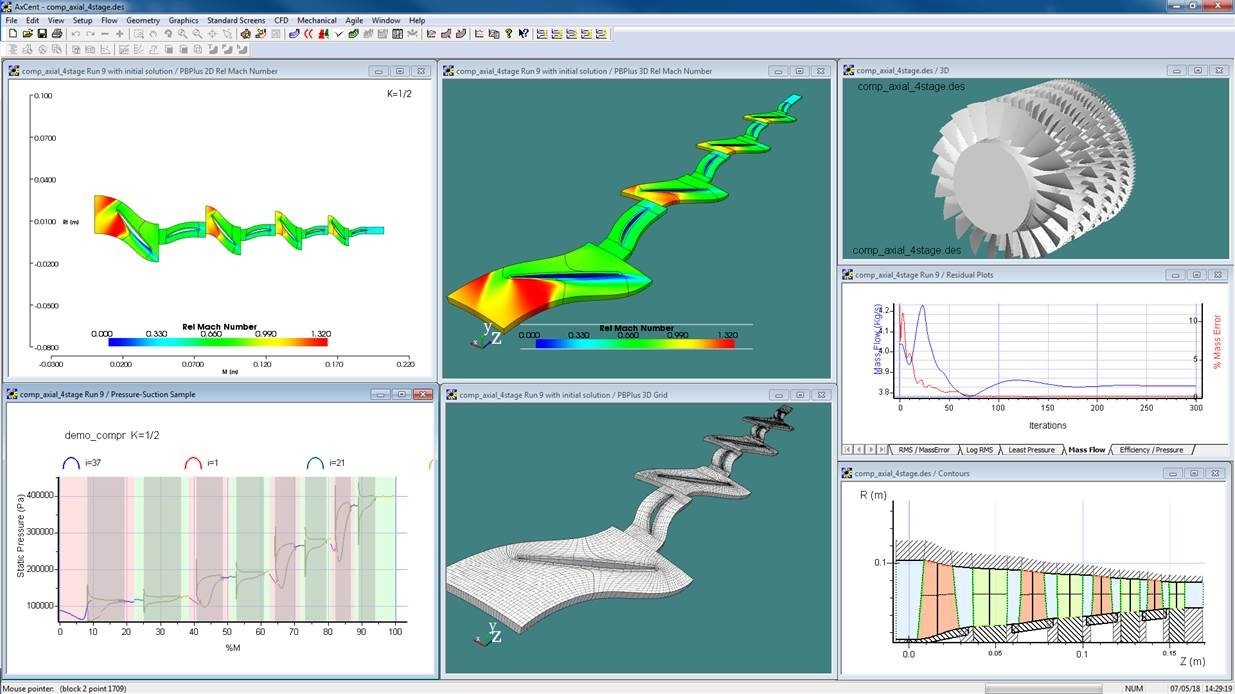

Four-stage axial compressor case study showing results from both Throughflow and Blade-to-Blade solvers:

Throughflow ran in under 25 seconds - best for axial machines

Blade-to-Blade ran in approximately one minute. It works on either axial or radial machines and runs fastest on radial machines.

Direct Integration to Other Programs

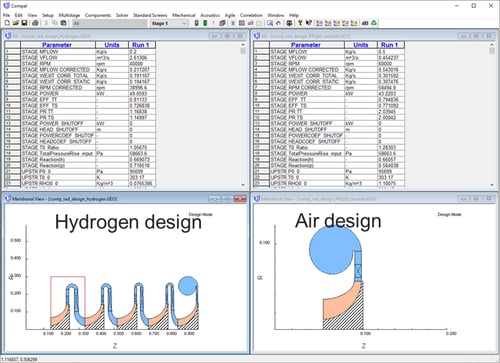

AxCent works through direct links with all Concepts NREC meanline programs including:

- COMPAL® (radial compressors)

- PUMPAL® (radial pumps)

- RITAL™ (radial turbines)

- FANPAL™ (axial and radial fans)

- AXIAL™ (axial and radial compressors and turbines)

- FINE/pbCFD and FINE™/Turbo (flow analysis)

- TurboOPT II™ (optimization)

AxCent can be started from any Concepts NREC meanline program (once the geometry has been set up), and can link the AxCent geometry back to the meanline design to rerun the analysis and regenerate the performance maps. Additionally, using TurboOPT II, the AxCent geometry can be linked to an internal optimizer or to a third-party optimizer such as modeFRONTIER, Isight™, VisualDOC, and IOSO.

Stress Analysis Integration

AxCent is fully integrated with Concepts NREC FEA stress analysis programs, Pushbutton FEA™. FEA stress, thermal and modal analysis can be conducted directly through the AxCent interface.

AxCent Interface to other Programs

AxCent is also compatible with many commercial and open source software packages. Some examples include:

- FLUENT®. Direct export of geometry or CFD grids through native FLUENT format files

- OpenFOAM®. Export of grid files and importation of output files through OpenFOAM formats

- CAD Systems. Export of IGES and STEP formats for seamless integration with virtually any CAD package

- Isight. Link to Isight optimization via XML format or directly through Concepts NREC’s TurboOPT II™ optimization software

- Import-export formats with Python scripting, XML format options, various other file output for seamless export to Concepts NREC CAM programs (the MAX-PAC™ suite)

Guide Curves

Software Highlights

-

AxCent easily handles the most complex blade geometry. A partial list of blade design features include:

-

Blade stacking of 2D cross sections

-

Blade restaggering around an arbitrary axis

-

Bowed blading defined by hub-to-shroud bow profiles

-

Bowed or sculpted element with arbitrary number of mid-span sections

-

Variable tip clearance on either end of the blade

-

Flow cuts and radial trims

-

Swept leading/trailing edges

-

Multiple, offset, and independent splitter blades

-

Irregular blade/splitter configurations for noise reduction

Other design features include:

-

Parameterized volute geometry generation

-

Split duct geometry

-

Fillets with constant or variable radius and aspect ratio

Recent 3D features include:

-

Cutaway view allows real-time cross sections to be viewed as the design is edited

-

3D overlays permit viewing of current, real-time changes on a transparent overlay

-

-

AxCent includes several options for real-time interactive flow analysis:

-

Inviscid streamline curvature solvers, including Concepts NREC's Multi-Stream Tube Solver (MST), are recognized in the industry as the best for centrifugal pumps and compressors

-

MST puts the power of real-time analysis in your hands. It enables you to immediately visualize the consequences of design changes on velocity, temperature, and pressure. You can look at multiple iterations in seconds, rather than the hours necessary to export each design to CAD for CFD analysis.

-

Using MST, you can significantly reduce the overall design cycle time by providing an optimized iteration for validation, rather then the more traditional iterative process that requires a lot more back and forth.

-

Design before editing

Design before editing Design after editing

Design after editing

And a number of CFD-based solvers:- Blade-to-blade is a powerful and rapid quasi-3D solver for quickly evaluating flow patterns across the channel

- Quickly provides validated feedback to resolve blade profiles for twist, camber and thickness

- Throughflow is another quasi-3D solver for rapid analysis of axial streamwise flow in compressors and turbines using industry-standard loss and deviation models

- Enables feedback in minutes compared to full CFD analysis

- Run multiple iterations to improve performance

- Full 3D CFD with an advanced full Navier-Stokes solver for comprehensive analysis using a seamless one-click interface with Cadence/NUMECA's FINE®/Turbo

Four-stage axial compressor case study showing results from both Throughflow and Blade-to-Blade solvers:

Throughflow ran in under 25 seconds - best for axial machines

Throughflow ran in under 25 seconds - best for axial machines

Blade-to-Blade ran in approximately one minute. It works on either axial or radial machines and runs fastest on radial machines.

-

-

AxCent works through direct links with all Concepts NREC meanline programs including:

-

COMPAL (radial compressors)

-

PUMPAL (radial pumps)

-

RITAL (radial turbines)

-

FANPAL (axial and radial fans)

-

AXIAL (axial and radial compressors and turbines)

-

FINE/pbCFD and FINE™/Turbo (flow analysis)

-

TurboOPT II (optimization)

AxCent can be started from any Concepts NREC meanline program (once the geometry has been set up), and can link the AxCent geometry back to the meanline design to rerun the analysis and regenerate the performance maps. Additionally, using TurboOPT II, the AxCent geometry can be linked to an internal optimizer or to a third-party optimizer such as modeFRONTIER, Isight™, VisualDOC, and IOSO.

-

-

AxCent is fully integrated with Concepts NREC FEA stress analysis programs, Pushbutton FEA™. FEA stress, thermal and modal analysis can be conducted directly through the AxCent interface.

-

AxCent is also compatible with many commercial and open source software packages. Some examples include:

-

FLUENT® - Direct export of geometry or CFD grids through native FLUENT format files

-

OpenFOAM® - Export of grid files and importation of output files through OpenFOAM formats

-

CAD Systems Export of IGES and STEP formats for seamless integration with virtually any CAD package

-

Isight - Link to Isight optimization via XML format or directly through Concepts NREC’s TurboOPT IIoptimization software

-

Import-export formats with Python scripting, XML format options, various other file output for seamless export to Concepts NREC CAM programs (the MAX-PAC suite)

-

AxCent easily handles the most complex blade geometry. A partial list of blade design features include:

-

Blade stacking of 2D cross sections

-

Blade restaggering around an arbitrary axis

-

Bowed blading defined by hub-to-shroud bow profiles

-

Bowed or sculpted element with arbitrary number of mid-span sections

-

Variable tip clearance on either end of the blade

-

Flow cuts and radial trims

-

Swept leading/trailing edges

-

Multiple, offset, and independent splitter blades

-

Irregular blade/splitter configurations for noise reduction

Other design features include:

-

Parameterized volute geometry generation

-

Split duct geometry

-

Fillets with constant or variable radius and aspect ratio

Recent 3D features include:

-

Cutaway view allows real-time cross sections to be viewed as the design is edited

-

3D overlays permit viewing of current, real-time changes on a transparent overlay

AxCent includes several options for real-time interactive flow analysis:

-

Inviscid streamline curvature solvers, including Concepts NREC's Multi-Stream Tube Solver (MST), are recognized in the industry as the best for centrifugal pumps and compressors

-

MST puts the power of real-time analysis in your hands. It enables you to immediately visualize the consequences of design changes on velocity, temperature, and pressure. You can look at multiple iterations in seconds, rather than the hours necessary to export each design to CAD for CFD analysis.

-

Using MST, you can significantly reduce the overall design cycle time by providing an optimized iteration for validation, rather then the more traditional iterative process that requires a lot more back and forth.

-

Design before editing

Design before editing

Design after editing

Design after editing

And a number of CFD-based solvers:

- Blade-to-blade is a powerful and rapid quasi-3D solver for quickly evaluating flow patterns across the channel

- Quickly provides validated feedback to resolve blade profiles for twist, camber and thickness

- Throughflow is another quasi-3D solver for rapid analysis of axial streamwise flow in compressors and turbines using industry-standard loss and deviation models

- Enables feedback in minutes compared to full CFD analysis

- Run multiple iterations to improve performance

- Full 3D CFD with an advanced full Navier-Stokes solver for comprehensive analysis using a seamless one-click interface with Cadence/NUMECA's FINE®/Turbo

Four-stage axial compressor case study showing results from both Throughflow and Blade-to-Blade solvers:

Throughflow ran in under 25 seconds - best for axial machines

Throughflow ran in under 25 seconds - best for axial machines

Blade-to-Blade ran in approximately one minute. It works on either axial or radial machines and runs fastest on radial machines.

AxCent works through direct links with all Concepts NREC meanline programs including:

-

COMPAL (radial compressors)

-

PUMPAL (radial pumps)

-

RITAL (radial turbines)

-

FANPAL (axial and radial fans)

-

AXIAL (axial and radial compressors and turbines)

-

FINE/pbCFD and FINE™/Turbo (flow analysis)

-

TurboOPT II (optimization)

AxCent can be started from any Concepts NREC meanline program (once the geometry has been set up), and can link the AxCent geometry back to the meanline design to rerun the analysis and regenerate the performance maps. Additionally, using TurboOPT II, the AxCent geometry can be linked to an internal optimizer or to a third-party optimizer such as modeFRONTIER, Isight™, VisualDOC, and IOSO.

AxCent is fully integrated with Concepts NREC FEA stress analysis programs, Pushbutton FEA™. FEA stress, thermal and modal analysis can be conducted directly through the AxCent interface.

AxCent is also compatible with many commercial and open source software packages. Some examples include:

-

FLUENT® - Direct export of geometry or CFD grids through native FLUENT format files

-

OpenFOAM® - Export of grid files and importation of output files through OpenFOAM formats

-

CAD Systems Export of IGES and STEP formats for seamless integration with virtually any CAD package

-

Isight - Link to Isight optimization via XML format or directly through Concepts NREC’s TurboOPT IIoptimization software

-

Import-export formats with Python scripting, XML format options, various other file output for seamless export to Concepts NREC CAM programs (the MAX-PAC suite)

Blade Geometry

AxCent easily handles the most complex blade geometry. A partial list of blade design features include:

- Blade stacking of 2D cross sections

- Blade restaggering around an arbitrary axis

- Bowed blading defined by hub-to-shroud bow profiles

- Bowed or sculpted element with arbitrary number of mid-span sections

- Variable tip clearance on either end of the blade

- Flow cuts and radial trims

- Swept leading/trailing edges

- Multiple, offset, and independent splitter blades

- Irregular blade/splitter configurations for noise reduction

Other design features include:

- Parameterized volute geometry generation

- Split duct geometry

- Fillets with constant or variable radius and aspect ratio

Recent 3D features include:

- Cutaway view allows real-time cross sections to be viewed as the design is edited

- 3D overlays permit viewing of current, real-time changes on a transparent overlay

Flow analysis

AxCent includes several options for real-time interactive flow analysis:

- Inviscid streamline curvature solvers, including Concepts NREC's Multi-Stream Tube Solver (MST), are recognized in the industry as the best for centrifugal pumps and compressors

- MST puts the power of real-time analysis in your hands. It enables you to immediately visualize the consequences of design changes on velocity, temperature, and pressure. You can look at multiple iterations in seconds, rather than the hours necessary to export each design to CAD for CFD analysis.

- Using MST, you can significantly reduce the overall design cycle time by providing an optimized iteration for validation, rather then the more traditional iterative process that requires a lot more back and forth.

Design before editing

Design after editing

Design after editing

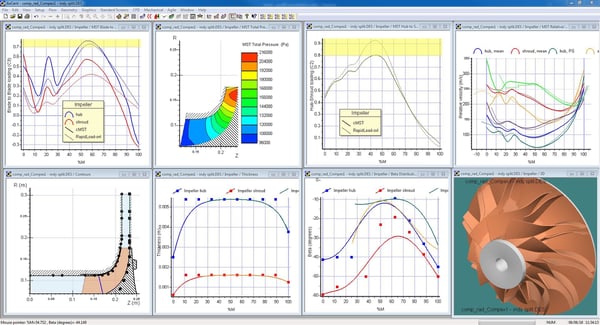

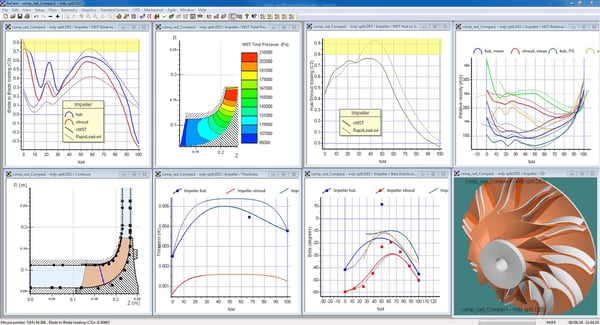

CFD Analysis

AxCent includes a number of CFD-based solvers:

- Blade-to-blade is a powerful and rapid quasi-3D solver for quickly evaluating flow patterns across the channel

- Quickly provides validated feedback to resolve blade profiles for twist, camber and thickness

- Throughflow is another quasi-3D solver for rapid analysis of axial streamwise flow in compressors and turbines using industry-standard loss and deviation models

- Enables feedback in minutes compared to full CFD analysis

- Run multiple iterations to improve performance

- Full 3D CFD with an advanced full Navier-Stokes solver for comprehensive analysis using a seamless one-click interface with Cadence/NUMECA's FINE®/Turbo

Four-stage axial compressor case study showing results from both Throughflow and Blade-to-Blade solvers:

Throughflow ran in under 25 seconds - best for axial machines

Blade-to-Blade ran in approximately one minute. It works on either axial or radial machines and runs fastest on radial machines.

Direct Integration to Other Programs

AxCent works through direct links with all Concepts NREC meanline programs including:

- COMPAL (radial compressors)

- PUMPAL (radial pumps)

- RITAL (radial turbines)

- FANPAL (axial and radial fans)

- AXIAL (axial and radial compressors and turbines)

- FINE/pbCFD and FINE™/Turbo (flow analysis)

- TurboOPT II (optimization)

AxCent can be started from any Concepts NREC meanline program (once the geometry has been set up), and can link the AxCent geometry back to the meanline design to rerun the analysis and regenerate the performance maps. Additionally, using TurboOPT II, the AxCent geometry can be linked to an internal optimizer or to a third-party optimizer such as modeFRONTIER, Isight™, VisualDOC, and IOSO.

Stress Analysis Integration

AxCent is fully integrated with Concepts NREC FEA stress analysis programs, Pushbutton FEA™. FEA stress, thermal and modal analysis can be conducted directly through the AxCent interface.

Interface to other Programs

AxCent is also compatible with many commercial and open source software packages. Some examples include:

- FLUENT®. Direct export of geometry or CFD grids through native FLUENT format files

- OpenFOAM®. Export of grid files and importation of output files through OpenFOAM formats

- CAD Systems. Export of IGES and STEP formats for seamless integration with virtually any CAD package

- Isight. Link to Isight optimization via XML format or directly through Concepts NREC’s TurboOPT IIoptimization software

- Import-export formats with Python scripting, XML format options, various other file output for seamless export to Concepts NREC CAM programs (the MAX-PAC suite)

Product Support

Customer-driven Improvement

Technical Support

Documentation

AxCent Brochure

Detailed 3D Design and Rapid 2D Flow Analysis Module for Turbomachinery

Find Your Rep

Our Sales Offices are strategically located around the globe to service all your turbomachinery needs.

Corporate Headquarters

217 Billings Farm Road

White River Junction, VT 05001-9486

Phone: 802-296-2321

Fax: 802-296-2325

Email: sales@conceptsnrec.com

North America Software Sales

Phone: 802-280-6181

Fax: 802-296-2325

Email: droberson@conceptsnrec.com

Upcoming Events

Tradeshows, Workshops, Webinars and more.

2021 Online Centrifugal and Axial Pumps Course - Modern Design, Performance, and Problem Solving

Application-Based Learning

Date: October 18 - 29, 2021

Time: 9:30 am - 1:00 pm EDT

Course Fee: $3500 USD

This course is designed to help engineers design, test, and run pumps and systems that are more efficient, more economical, and more reliable. Engineers will come to understand the best state-of-the-art design practices and learn the latest theories on performance, cavitation, dynamic forces, and noise. The course will review the latest advances in design tools and will provide expert and relevant instruction to designers on pump design optimization. Nearly half of all the teaching is focused on actual commercial design cases with measured data for confirmation.

2021 Trade Show: ComVac Asia

Visit Concepts NREC China at the ComVac Asia

Date: October 26-29, 2021

Location: Shanghai, China

To learn more, visit https://www.comvac-asia.com/index.php?lang=en

I came to the realization that we needed some objective insight.

We were working well with the OEM but even with our combined efforts, we were struggling to get a critical compressor to pass performance on their test stand. Although I'd never directly done business with Concepts NREC I was familiar with them and their capability so I chose to contact them when I came to the realization that we needed some objective insight. Concepts NREC fielded my cold call and immediately engaged their expertise in a complex problem that was also challenged by schedule constraints. They provided increased understanding of an already complex CFD which resulted in increased confidence that the proposed solution would succeed on the next test stand attempt (which it did!). We are pleased to have had the help of Concepts NREC and now have a well-performing compressor in our process.”

Bryan Barrington

Senior Advisor - Machinery Engineering