Pushbutton FEA™

FEA for 3D Stress Analysis

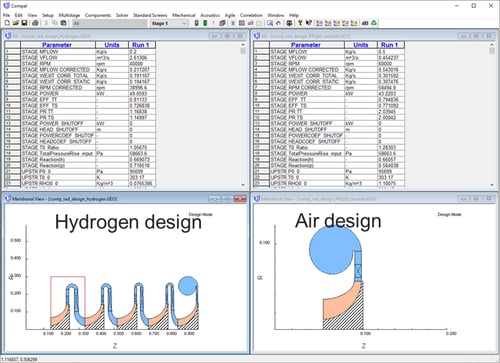

Producing designs that meet both performance and product life criteria is a fundamental component of today’s advanced turbomachinery marketplace. Pushbutton FEA™ is designed to both extend and integrate into your design environment. This enables aerodynamic and structural design to be performed concurrently within AxCent® utilizing the integrated FEA tools. Since this can be done as soon as you have initial blade definition, it means structural analysis and life assessment can be performed earlier in the design process than ever before.

Complex radial and axial geometries can be easily modeled with the parametric tools available within Pushbutton FEA, which has a powerful and accurate linear finite element solver.

%20and%20Applied%20Relative%20Total%20Temperatures%20to%20FEM%20(right).jpg?width=600&name=FEM%20of%20Radial%20Turbine%20(left)%20and%20Applied%20Relative%20Total%20Temperatures%20to%20FEM%20(right).jpg)

FEM of Radial Turbine (left) and Applied Relative Total Temperatures to FEM (right)

Aero Load Mapping

This feature enables users to automatically link the CFD results to the structural finite element model (FEM). As a result, the static pressures, relative total temperatures, and the heat-transfer coefficients are automatically mapped to all of the flow path surfaces in the FEM.

In addition to the automated mapping, the user can apply any pressure, temperature, or heat-transfer coefficient distribution to the non-flow path surfaces (secondary flow paths) such as the nose, bore, or backface.

Designing turbomachinery is an inherently iterative process. The ability to update aero loading on an FEM with only a few “mouse clicks” within a robust design environment eliminates the need to move back and forth between CAD, analysis software and the design software. With Concepts NREC's solution, it is all encapsulated into one closed loop.

The benefits of Pushbutton FEA Aero Load Mapping are:

- Increasing the accuracy of the structural simulations and stress predictions your mechanical/structural engineers produce.

- Reducing the time required for the overall design process by many hours or even days.

- Enables more iterations, within a given design time, to achieve improved performance/durability balance.

Software Highlights - Aero Load Mapping

-

This feature enables users to automatically link the CFD results to the structural finite element model (FEM). As a result, the static pressures, relative total temperatures, and the heat-transfer coefficients are automatically mapped to all of the flow path surfaces in the FEM.

In addition to the automated mapping, the user can apply any pressure, temperature, or heat-transfer coefficient distribution to the non-flow path surfaces (secondary flow paths) such as the nose, bore, or backface.

Designing turbomachinery is an inherently iterative process. The ability to update aero loading on an FEM with only a few “mouse clicks” within a robust design environment eliminates the need to move back and forth between CAD, analysis software and the design software. With Concepts NREC's solution, it is all encapsulated into one closed loop.

The benefits of Pushbutton FEA Aero Load Mapping are:

- Increasing the accuracy of the structural simulations and stress predictions your mechanical/structural engineers produce.

- Reducing the time required for the overall design process by many hours or even days.

- Enables more iterations, within a given design time, to achieve improved performance/durability balance.

%20and%20Applied%20Relative%20Total%20Temperatures%20to%20FEM%20(right).jpg?width=1255&name=FEM%20of%20Radial%20Turbine%20(left)%20and%20Applied%20Relative%20Total%20Temperatures%20to%20FEM%20(right).jpg)

FEM of Radial Turbine (left) and Applied Relative Total Temperatures to FEM (right)

-

An Interference Diagram is a qualitative analysis tool that relates a components natural frequencies to operating speeds, sources of external excitation, and mode shapes. This is an automated post-processing feature of PushButton FEA performed after completing a cyclic symmetry modal analysis (EIGEN value extraction analysis).

Interference Diagrams highlight potential problem frequencies and provide guidance on how to avoid these frequencies early in the design process - avoiding costly and time-consuming redesign work.

Using an Interference Diagram also breaks down historical design barriers related to rotating and stationary blade counts and unleashes a broader range of design possibilities.

The biggest benefit of this powerful tool is the ability to design early on around known excitations in the system, thereby lowering the risk of (avoiding) vibratory failure, fractures, and high-cycle fatigue.

-

Both quadratic and linear elements are available for all analysis types. Thermal, static, and modal solvers are available. Cut faces can be modeled using both cyclic and coupled DOF boundary conditions. All of the load information is created from the previously calculated aerodynamic conditions using rapid load, MST or CFD. These aerodynamic loads are applied to the FEA model elements as convective heat transfers and pressures applied to the external element faces. Thermal stresses can be included in the static analysis, and the static stresses can also be incorporated as a pre-stress condition for the modal solver. Spin or centrifugal softening is available, as is the use of a lumped mass matrix instead of the default consistent mass matrix.

-

There are no files involved in the transfer of information from the aero to the mechanical design, so modifications to the aero definitions are immediately updated into the mechanical design. This reduces the likelihood of the two processes becoming desynchronized due to outdated definition files.

-

In addition to the integrated Pushbutton FEA solver, the software maintains its links with other FEA solvers such as ANSYS®, COSMOS/M®, NASTRAN™ and ABAQUS® and therefore can also be utilized with your existing tools. Using a 3rd party solver means that Pushbutton FEA becomes a powerful and intuitive geometry design tool with grid generation. Some post-processing capability is also available, such as Goodman, Campbell, and interference diagrams.

-

For the Concepts NREC Pushbutton FEA solver, full 3D post-processing is available. Displaced geometry color surface contour plots of temperature, displacement, and stresses can be overlaid with undisplaced wireframes, making it easier to visualize the effects of the load conditions. There is also modal displacement-based animation which can be used to view the mode shapes. This is particularly useful for visualizing the typical modal displaced shapes.

This feature enables users to automatically link the CFD results to the structural finite element model (FEM). As a result, the static pressures, relative total temperatures, and the heat-transfer coefficients are automatically mapped to all of the flow path surfaces in the FEM.

In addition to the automated mapping, the user can apply any pressure, temperature, or heat-transfer coefficient distribution to the non-flow path surfaces (secondary flow paths) such as the nose, bore, or backface.

Designing turbomachinery is an inherently iterative process. The ability to update aero loading on an FEM with only a few “mouse clicks” within a robust design environment eliminates the need to move back and forth between CAD, analysis software and the design software. With Concepts NREC's solution, it is all encapsulated into one closed loop.

The benefits of Pushbutton FEA Aero Load Mapping are:

- Increasing the accuracy of the structural simulations and stress predictions your mechanical/structural engineers produce.

- Reducing the time required for the overall design process by many hours or even days.

- Enables more iterations, within a given design time, to achieve improved performance/durability balance.

%20and%20Applied%20Relative%20Total%20Temperatures%20to%20FEM%20(right).jpg?width=1255&name=FEM%20of%20Radial%20Turbine%20(left)%20and%20Applied%20Relative%20Total%20Temperatures%20to%20FEM%20(right).jpg)

FEM of Radial Turbine (left) and Applied Relative Total Temperatures to FEM (right)

An Interference Diagram is a qualitative analysis tool that relates a components natural frequencies to operating speeds, sources of external excitation, and mode shapes. This is an automated post-processing feature of PushButton FEA performed after completing a cyclic symmetry modal analysis (EIGEN value extraction analysis).

Interference Diagrams highlight potential problem frequencies and provide guidance on how to avoid these frequencies early in the design process - avoiding costly and time-consuming redesign work.

Using an Interference Diagram also breaks down historical design barriers related to rotating and stationary blade counts and unleashes a broader range of design possibilities.

The biggest benefit of this powerful tool is the ability to design early on around known excitations in the system, thereby lowering the risk of (avoiding) vibratory failure, fractures, and high-cycle fatigue.

Both quadratic and linear elements are available for all analysis types. Thermal, static, and modal solvers are available. Cut faces can be modeled using both cyclic and coupled DOF boundary conditions. All of the load information is created from the previously calculated aerodynamic conditions using rapid load, MST or CFD. These aerodynamic loads are applied to the FEA model elements as convective heat transfers and pressures applied to the external element faces. Thermal stresses can be included in the static analysis, and the static stresses can also be incorporated as a pre-stress condition for the modal solver. Spin or centrifugal softening is available, as is the use of a lumped mass matrix instead of the default consistent mass matrix.

There are no files involved in the transfer of information from the aero to the mechanical design, so modifications to the aero definitions are immediately updated into the mechanical design. This reduces the likelihood of the two processes becoming desynchronized due to outdated definition files.

In addition to the integrated Pushbutton FEA solver, the software maintains its links with other FEA solvers such as ANSYS®, COSMOS/M®, NASTRAN™ and ABAQUS® and therefore can also be utilized with your existing tools. Using a 3rd party solver means that Pushbutton FEA becomes a powerful and intuitive geometry design tool with grid generation. Some post-processing capability is also available, such as Goodman, Campbell, and interference diagrams.

For the Concepts NREC Pushbutton FEA solver, full 3D post-processing is available. Displaced geometry color surface contour plots of temperature, displacement, and stresses can be overlaid with undisplaced wireframes, making it easier to visualize the effects of the load conditions. There is also modal displacement-based animation which can be used to view the mode shapes. This is particularly useful for visualizing the typical modal displaced shapes.

Aero Load Mapping

his feature enables users to automatically link the CFD results to the structural finite element model (FEM). As a result, the static pressures, relative total temperatures, and the heat-transfer coefficients are automatically mapped to all of the flow path surfaces in the FEM.

In addition to the automated mapping, the user can apply any pressure, temperature, or heat-transfer coefficient distribution to the non-flow path surfaces (secondary flow paths) such as the nose, bore, or backface.

Designing turbomachinery is an inherently iterative process. The ability to update aero loading on an FEM with only a few “mouse clicks” within a robust design environment eliminates the need to move back and forth between CAD, analysis software and the design software. With Concepts NREC's solution, it is all encapsulated into one closed loop.

The benefits of Pushbutton FEA Aero Load Mapping are:

- Increasing the accuracy of the structural simulations and stress predictions your mechanical/structural engineers produce.

- Reducing the time required for the overall design process by many hours or even days.

- Enables more iterations, within a given design time, to achieve improved performance/durability balance.

%20and%20Applied%20Relative%20Total%20Temperatures%20to%20FEM%20(right).jpg?width=600&name=FEM%20of%20Radial%20Turbine%20(left)%20and%20Applied%20Relative%20Total%20Temperatures%20to%20FEM%20(right).jpg)

FEM of Radial Turbine (left) and Applied Relative Total Temperatures to FEM (right)

Interference Diagrams

An Interference Diagram is a qualitative analysis tool that relates a components natural frequencies to operating speeds, sources of external excitation, and mode shapes. This is an automated post-processing feature of PushButton FEA performed after completing a cyclic symmetry modal analysis (EIGEN value extraction analysis).

Interference Diagrams highlight potential problem frequencies and provide guidance on how to avoid these frequencies early in the design process - avoiding costly and time-consuming redesign work.

Using an Interference Diagram also breaks down historical design barriers related to rotating and stationary blade counts and unleashes a broader range of design possibilities.

The biggest benefit of this powerful tool is the ability to design early on around known excitations in the system, thereby lowering the risk of (avoiding) vibratory failure, fractures, and high-cycle fatigue.

FEA Solver

Both quadratic and linear elements are available for all analysis types. Thermal, static, and modal solvers are available. Cut faces can be modeled using both cyclic and coupled DOF boundary conditions. All of the load information is created from the previously calculated aerodynamic conditions using rapid load, MST or CFD. These aerodynamic loads are applied to the FEA model elements as convective heat transfers and pressures applied to the external element faces. Thermal stresses can be included in the static analysis, and the static stresses can also be incorporated as a pre-stress condition for the modal solver. Spin or centrifugal softening is available, as is the use of a lumped mass matrix instead of the default consistent mass matrix.

Closely Coupled Aero & Mechanical

There are no files involved in the transfer of information from the aero to the mechanical design, so modifications to the aero definitions are immediately updated into the mechanical design. This reduces the likelihood of the two processes becoming desynchronized due to outdated definition files.

Support of Other Solvers

In addition to the integrated Pushbutton FEA solver, the software maintains its links with other FEA solvers such as ANSYS®, COSMOS/M®, NASTRAN™ and ABAQUS® and therefore can also be utilized with your existing tools. Using a 3rd party solver means that Pushbutton FEA becomes a powerful and intuitive geometry design tool with grid generation. Some post-processing capability is also available, such as Goodman, Campbell, and interference diagrams.

Post-Processing

For the Concepts NREC Pushbutton FEA solver, full 3D post-processing is available. Displaced geometry color surface contour plots of temperature, displacement, and stresses can be overlaid with undisplaced wireframes, making it easier to visualize the effects of the load conditions. There is also modal displacement-based animation which can be used to view the mode shapes. This is particularly useful for visualizing the typical modal displaced shapes.

Product Support

Customer-driven Improvement

Technical Support

Documentation

Interference Diagrams

An Interference Diagram is a qualitative analysis tool that relates a components natural frequencies to operating speeds, sources of external excitation, and mode shapes. This is an automated post-processing feature of PushButton FEA performed after completing a cyclic symmetry modal analysis (EIGEN value extraction analysis).

Interference Diagrams highlight potential problem frequencies and provide guidance on how to avoid these frequencies early in the design process - avoiding costly and time-consuming redesign work.

Using an Interference Diagram also breaks down historical design barriers related to rotating and stationary blade counts and unleashes a broader range of design possibilities.

The biggest benefit of this powerful tool is the ability to design early on around known excitations in the system, thereby lowering the risk of (avoiding) vibratory failure, fractures, and high-cycle fatigue.

FEA Solver

Both quadratic and linear elements are available for all analysis types. Thermal, static, and modal solvers are available. Cut faces can be modeled using both cyclic and coupled DOF boundary conditions. All of the load information is created from the previously calculated aerodynamic conditions using rapid load, MST or CFD. These aerodynamic loads are applied to the FEA model elements as convective heat transfers and pressures applied to the external element faces. Thermal stresses can be included in the static analysis, and the static stresses can also be incorporated as a pre-stress condition for the modal solver. Spin or centrifugal softening is available, as is the use of a lumped mass matrix instead of the default consistent mass matrix.

Closely Coupled Aero & Mechanical

There are no files involved in the transfer of information from the aero to the mechanical design, so modifications to the aero definitions are immediately updated into the mechanical design. This reduces the likelihood of the two processes becoming desynchronized due to outdated definition files.

Support of Other Solvers

In addition to the integrated Pushbutton FEA solver, the software maintains its links with other FEA solvers such as ANSYS®, COSMOS/M®, NASTRAN™ and ABAQUS® and therefore can also be utilized with your existing tools. Using a 3rd party solver means that Pushbutton FEA becomes a powerful and intuitive geometry design tool with grid generation. Some post-processing capability is also available, such as Goodman, Campbell, and interference diagrams.

Post-Processing

For the Concepts NREC Pushbutton FEA solver, full 3D post-processing is available. Displaced geometry color surface contour plots of temperature, displacement, and stresses can be overlaid with undisplaced wireframes, making it easier to visualize the effects of the load conditions. There is also modal displacement-based animation which can be used to view the mode shapes. This is particularly useful for visualizing the typical modal displaced shapes.

Above all, Pushbutton FEA is designed to be simple and intuitive for the non-FEA professional, while still providing the necessary power and flexibility for the structural design professional.

pbFEA Brochure

Pushbutton FEA™ enables aerodynamic and structural design to be performed concurrently within AxCent® utilizing the integrated

FEA tools.

Find Your Rep

Our Sales Offices are strategically located around the globe to service all your turbomachinery needs.

Corporate Headquarters

217 Billings Farm Road

White River Junction, VT 05001-9486

Phone: 802-296-2321

Fax: 802-296-2325

Email: sales@conceptsnrec.com

North America Software Sales

Phone: 802-280-6181

Fax: 802-296-2325

Email: droberson@conceptsnrec.com

Upcoming Events

Tradeshows, Workshops, Webinars and more.

2021 Online Centrifugal and Axial Pumps Course - Modern Design, Performance, and Problem Solving

Application-Based Learning

Date: October 18 - 29, 2021

Time: 9:30 am - 1:00 pm EDT

Course Fee: $3500 USD

This course is designed to help engineers design, test, and run pumps and systems that are more efficient, more economical, and more reliable. Engineers will come to understand the best state-of-the-art design practices and learn the latest theories on performance, cavitation, dynamic forces, and noise. The course will review the latest advances in design tools and will provide expert and relevant instruction to designers on pump design optimization. Nearly half of all the teaching is focused on actual commercial design cases with measured data for confirmation.

2021 Trade Show: ComVac Asia

Visit Concepts NREC China at the ComVac Asia

Date: October 26-29, 2021

Location: Shanghai, China

To learn more, visit https://www.comvac-asia.com/index.php?lang=en

I came to the realization that we needed some objective insight.

We were working well with the OEM but even with our combined efforts, we were struggling to get a critical compressor to pass performance on their test stand. Although I'd never directly done business with Concepts NREC I was familiar with them and their capability so I chose to contact them when I came to the realization that we needed some objective insight. Concepts NREC fielded my cold call and immediately engaged their expertise in a complex problem that was also challenged by schedule constraints. They provided increased understanding of an already complex CFD which resulted in increased confidence that the proposed solution would succeed on the next test stand attempt (which it did!). We are pleased to have had the help of Concepts NREC and now have a well-performing compressor in our process.”

Bryan Barrington

Senior Advisor - Machinery Engineering