Custom Manufacturing Resources

Prototypes & Production Runs

Concepts NREC offers custom manufacturing of high-quality turbomachinery parts applicable to a broad-range of industries, including aviation, aerospace, automotive, commercial, industrial, refrigeration, HVAC, and oil & gas.

Our complete Art-to-Part solution means we can offer you more than just cutting metal. We can suggest more efficient manufacturing methods, processes, and designs that will meet your needs, while lowering your production costs.

We specialize in delivering high-quality prototypes and production runs (tens to hundreds) of difficult to manufacture turbomachinery parts, including integrally-shrouded impellers and blisks. Concepts NREC is ISO 9001:2015 and AS9100:2016 certified and committed to providing our customers with products and services that meet international quality standards. We offer extremely competitive pricing, quick turn-times, and outstanding customer service. A key strength is our flexibility to work with your schedule.

Capabilities

- Simultaneous 5-Axis up to 39 in (99.06 cm) diameter

- Turning up to 39 in (99.06 cm) diameter

- CMM Inspection with Zeiss Blade Pro for in-depth dimensional analysis of turbine blades

- Assembly & Testing

How can we help you?

Are you commercializing a new product and need someone to manufacture the initial quantities as you ramp up for large-scale production? We can help. Do you have a really challenging low-volume part? Outsource it to us! Have you discontinued a product, but still need small quantities for maintenance and repair? Let us handle it. We want to be your trusted partner for small to medium production runs.

A shrouded (enclosed) impeller, machined from a single piece of stock

A shrouded (enclosed) impeller, machined from a single piece of stock

A large propeller on the C52

State of the Art Machines

Concepts NREC’s state-of-the-art manufacturing center features 5-axis CNC milling machines, (including a new Hermle C52 mill/turn), horizontal and vertical CNC lathes, and a Zeiss coordinate measuring machine (CMM) for precision inspection.

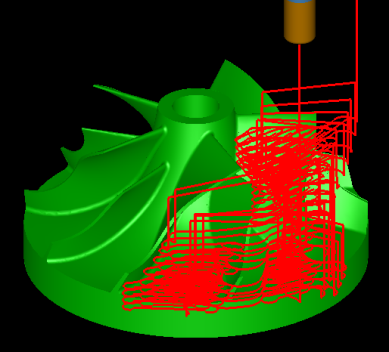

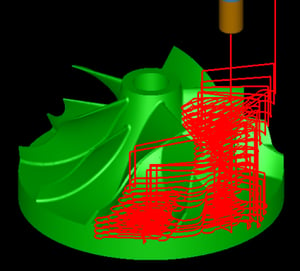

Best Software for Turbomachinery

We use MAX-PAC™ Computer-Aided Manufacturing (CAM) software, long recognized as the best CAM software for 5-axis milling of rotating bladed components, including impellers, blisks, and rotors. And, because we make the software, our machinist can work directly with developers to continuously improve the outcomes.

MAX-PAC's Material Removal Simulation (MRS)

MAX-PAC's Material Removal Simulation (MRS)

Trust the Experts in Turbomachinery

For over 60 years, we have helped leading global OEMs to improve the performance and manufacturability of their turbomachines.

This is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient.

Below is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient

Below is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient.

Below is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient.

What our customers say about quality, service and performance

"As a requisitioner / buyer of impeller machinings I rate Concepts NREC's Manufactured Products Business Unit very highly in the areas of customer service, cost, quality & delivery performance."

“Much thanks to your ability to exceed your customers expectation on throughput… Quality just as good as expected, basically perfect.”

"Customer service is really good - they answer questions and concerns in a timely manner."

"High performance from quote to delivery"

"Concepts' decision to stock material that is qualified to our specifications is a great competitive advantage. Their willingness to provide technical / commercial informational support makes them my "go-to" supplier for milled impellers."

How can we help you?

Are you commercializing a new product and need someone to manufacture the initial quantities as you ramp up for large-scale production? We can help. Do you have a really challenging low-volume part? Outsource it to us! Have you discontinued a product, but still need small quantities for maintenance and repair? Let us handle it. We want to be your trusted partner for small to medium production runs.

Are you commercializing a new product and need someone to manufacture the initial quantities as you ramp up for large-scale production? We can help. Do you have a really challenging low-volume part? Outsource it to us! Have you discontinued a product, but still need small quantities for maintenance and repair? Let us handle it. We want to be your trusted partner for small to medium production runs.

State of the Art Machines

Concepts NREC’s state-of-the-art manufacturing center features 5-axis CNC milling machines, (including a new Hermle C52 mill/turn), horizontal and vertical CNC lathes, and a Zeiss coordinate measuring machine (CMM) for precision inspection.

Concepts NREC’s state-of-the-art manufacturing center features 5-axis CNC milling machines, (including a new Hermle C52 mill/turn), horizontal and vertical CNC lathes, and a Zeiss coordinate measuring machine (CMM) for precision inspection.

Best Software for Turbomachinery

We use MAX-PAC™ Computer-Aided Manufacturing (CAM) software, long recognized as the best CAM software for 5-axis milling of rotating bladed components, including impellers, blisks, and rotors. And, because we make the software, our machinist can work directly with developers to continuously improve the outcomes.

We use MAX-PAC™ Computer-Aided Manufacturing (CAM) software, long recognized as the best CAM software for 5-axis milling of rotating bladed components, including impellers, blisks, and rotors. And, because we make the software, our machinist can work directly with developers to continuously improve the outcomes.

What We Offer

Services

- Heat Treat

- Wire/Sinker EDM

- Spline/V-tooth/Drive Pins/Polygon

- Grinding

- Abradable Coating

- Brazing

- Polishing

- Shot Peening

- Paint

- Passivation

- Electroplating

- Welding

- Dynamic Balancing

- Overspeed Testing

- Liquid Penetrant Testing

- Ultrasonic Testing

- Laser Scanning

- Additive Manufacturing

Materials

- Aluminum

- Stainless Steel

- Inconel

- Titanium

Part Types

- Pump Impellers (open & integrally shrouded)

- Compressor impellers (open & integrally shrouded)

- Turbines rotors/impellers

- Blisks

- Housings/Volutes

- Bladed stators/guide vanes (IGVs)

- Diffusers

- Shrouds

Tolerances

- Dimensional to +/- 0.0001”

- Surface finishes to 8 µ in Ra

Agile Products Support (APS)

APS is Concepts NREC’s software maintenance and support program that elevates us from just a software provider to a valued partner.

An APS subscription is included with all annual licenses and is a highly-recommended option for perpetual software licenses. Every software customer is supported for one month following purchase for any installation questions that may arise. Learn more on the Agile Products Support Membership Benefits Datasheet.

- Free software updates

- One business day response times

- Expert technical assistance

- Major discounts on software workshops

- Discounted professional development course

- Annual balloting system for development planning

- Annual Meetings

Manufacturing Brochure

Our specialty is manufacturing prototypes and short production runs of your most challenging turbomachinery parts on our 5-axis CNC machines.