Fans & Blowers Design

Software Highlights

2020 Release Features

-

AXIAL's state-of-the-art loss modeling system allows for the independent selection of loss models by blade row and loss split by loss component (i.e., profile, secondary flow, partial admission, wetness losses, and more). Industry-standard loss models are included for turbines.

- Ainley-Mathieson

- Dunham-Came

- Kacker-Okapuu

- Moustapha-Kacker

Loss models are included for compressors.

- Koch & Smith

- Wright & Miller

-

Real Fluid thermodynamics are integral to AXIAL, which includes built-in support for perfect and semiperfect fluid properties. Real Fluid properties are provided through several different fluid databases including DB Robinson Real Fluid Properties, NIST, and ASME Steam. AXIAL also supports condensed gases, user-modifiable fluid properties, and the barotropic fluid thermodynamic model.

-

AXIAL includes a flexible user-friendly interface and built-in performance mapping. Context-sensitive help is included for each parameter in each table cell. HTML help is also available.

-

AXIAL utilizes integrated performance map plotting. Users can view blade angles and velocity triangles at the rotor inlet and exit, as well as view results in a flexible spreadsheet-like table view. Tables are customizable through separate filters, with the user able to create any number of filters, select what to display, and customize the labels as well.

-

Users can control AXIAL from an external program by means of Object Linking and Embedding (OLE) automation. OLE automation supports the full control of data entry, program execution, and result retrieval. External programs can be written in Visual Basic, C++, FORTRAN, or any other language that supports the Microsoft® OLE standard.

-

AxCent files can be started from within AXIAL, with the initial geometry and flow parameters transferred automatically to AxCent for blade shaping/stacking, blade-to-blade analysis, throughflow analysis, and further transfer to CFD and FEA programs. The user can also update the AXIAL solution from AxCent, transferring the more complete geometry from AxCent back to the meanline model.

AXIAL's state-of-the-art loss modeling system allows for the independent selection of loss models by blade row and loss split by loss component (i.e., profile, secondary flow, partial admission, wetness losses, and more). Industry-standard loss models are included for turbines.

- Ainley-Mathieson

- Dunham-Came

- Kacker-Okapuu

- Moustapha-Kacker

Loss models are included for compressors.

- Koch & Smith

- Wright & Miller

Real Fluid thermodynamics are integral to AXIAL, which includes built-in support for perfect and semiperfect fluid properties. Real Fluid properties are provided through several different fluid databases including DB Robinson Real Fluid Properties, NIST, and ASME Steam. AXIAL also supports condensed gases, user-modifiable fluid properties, and the barotropic fluid thermodynamic model.

AXIAL includes a flexible user-friendly interface and built-in performance mapping. Context-sensitive help is included for each parameter in each table cell. HTML help is also available.

AXIAL utilizes integrated performance map plotting. Users can view blade angles and velocity triangles at the rotor inlet and exit, as well as view results in a flexible spreadsheet-like table view. Tables are customizable through separate filters, with the user able to create any number of filters, select what to display, and customize the labels as well.

Users can control AXIAL from an external program by means of Object Linking and Embedding (OLE) automation. OLE automation supports the full control of data entry, program execution, and result retrieval. External programs can be written in Visual Basic, C++, FORTRAN, or any other language that supports the Microsoft® OLE standard.

AxCent files can be started from within AXIAL, with the initial geometry and flow parameters transferred automatically to AxCent for blade shaping/stacking, blade-to-blade analysis, throughflow analysis, and further transfer to CFD and FEA programs. The user can also update the AXIAL solution from AxCent, transferring the more complete geometry from AxCent back to the meanline model.

Loss Modeling

AXIAL's state-of-the-art loss modeling system allows for the independent selection of loss models by blade row and loss split by loss component (i.e., profile, secondary flow, partial admission, wetness losses, and more). Industry-standard loss models are included for turbines.

- Ainley-Mathieson

- Dunham-Came

- Kacker-Okapuu

- Moustapha-Kacker

Loss models are included for compressors.

- Koch & Smith

- Wright & Miller

Real Fluid Thermodynamics

Real Fluid thermodynamics are integral to AXIAL, which includes built-in support for perfect and semiperfect fluid properties. Real Fluid properties are provided through several different fluid databases including DB Robinson Real Fluid Properties, NIST, and ASME Steam. AXIAL also supports condensed gases, user-modifiable fluid properties, and the barotropic fluid thermodynamic model.

User-Friendly Features

AXIAL includes a flexible user-friendly interface and built-in performance mapping. Context-sensitive help is included for each parameter in each table cell. HTML help is also available.

Graphical and Tabular View of Results

AXIAL utilizes integrated performance map plotting. Users can view blade angles and velocity triangles at the rotor inlet and exit, as well as view results in a flexible spreadsheet-like table view. Tables are customizable through separate filters, with the user able to create any number of filters, select what to display, and customize the labels as well.

OLE Automation Support

Users can control AXIAL from an external program by means of Object Linking and Embedding (OLE) automation. OLE automation supports the full control of data entry, program execution, and result retrieval. External programs can be written in Visual Basic, C++, FORTRAN, or any other language that supports the Microsoft® OLE standard.

Integration with AxCent®

AxCent files can be started from within AXIAL, with the initial geometry and flow parameters transferred automatically to AxCent for blade shaping/stacking, blade-to-blade analysis, throughflow analysis, and further transfer to CFD and FEA programs. The user can also update the AXIAL solution from AxCent, transferring the more complete geometry from AxCent back to the meanline model.

Other AXIAL Features

- Estimate of hub and tip flow parameters

- Evaluation of compressor stall and choking conditions for both compressors and turbines

- Design analysis of multiple choked and stalled components, along with mass flow, pressure ratio, and power

- Setup of an arbitrary sequence of stage elements (rotor, stator, duct, IGV, EGV, etc.)

Product Support

Customer-driven Improvement

Technical Support

Documentation

Data Sheet

Detailed 3D Design and Rapid 2D Flow Analysis Module for Turbomachinery

Find Your Rep

Our Sales Offices are strategically located around the globe to service all your turbomachinery needs.

Corporate Headquarters

217 Billings Farm Road

White River Junction, VT 05001-9486

Phone: 802-296-2321

Fax: 802-296-2325

Email: sales@conceptsnrec.com

North America Software Sales

Phone: 802-280-6181

Fax: 802-296-2325

Email: droberson@conceptsnrec.com

Upcoming Events

Tradeshows, Workshops, Webinars and more.

2021 Online Centrifugal and Axial Pumps Course - Modern Design, Performance, and Problem Solving

Application-Based Learning

Date: October 18 - 29, 2021

Time: 9:30 am - 1:00 pm EDT

Course Fee: $3500 USD

This course is designed to help engineers design, test, and run pumps and systems that are more efficient, more economical, and more reliable. Engineers will come to understand the best state-of-the-art design practices and learn the latest theories on performance, cavitation, dynamic forces, and noise. The course will review the latest advances in design tools and will provide expert and relevant instruction to designers on pump design optimization. Nearly half of all the teaching is focused on actual commercial design cases with measured data for confirmation.

2021 Trade Show: ComVac Asia

Visit Concepts NREC China at the ComVac Asia

Date: October 26-29, 2021

Location: Shanghai, China

To learn more, visit https://www.comvac-asia.com/index.php?lang=en

I came to the realization that we needed some objective insight.

We were working well with the OEM but even with our combined efforts, we were struggling to get a critical compressor to pass performance on their test stand. Although I'd never directly done business with Concepts NREC I was familiar with them and their capability so I chose to contact them when I came to the realization that we needed some objective insight. Concepts NREC fielded my cold call and immediately engaged their expertise in a complex problem that was also challenged by schedule constraints. They provided increased understanding of an already complex CFD which resulted in increased confidence that the proposed solution would succeed on the next test stand attempt (which it did!). We are pleased to have had the help of Concepts NREC and now have a well-performing compressor in our process.”

Bryan Barrington

Senior Advisor - Machinery Engineering

Design Software Solution for Fans & Blowers

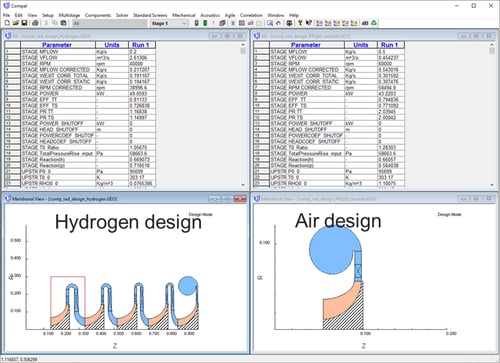

The Concepts NREC FINE/Agile for Fans bundle delivers an integrated tool chain for the entire component design workflow of a fan or blowers. Starting with a wizard-based 1D design and analysis in FANPAL™, the designer will be quickly guided to a flow path that meets their specifications. This will result in a machine that has appropriate sizing, number of stages, and initial performance predictions. From there, more detailed analysis may be employed to ascertain the feasibility of the machine by leveraging such tools as multi-point analysis to create performance maps.

The Agile link is used to seamlessly transfer all data from FANPAL™ to our flagship 3D design product AxCent®. This is where the designer can refine the design by modifying distributions such as beta angle, lean, blade thickness, and many other geometric design parameters accompanied by real time updates of the 3D geometry. These changes can be moved forward into 3D CFD preparation or the Agile link may be used to return to FANPAL™ and determine the impact of the 3D geometry parameterization on the 1D analysis.

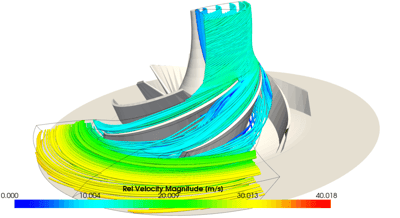

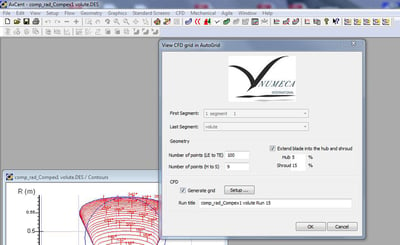

All pre-processing for 3D CFD is completed using TurboLink™. Here, the designer can provide all grid parameters, loads, and boundary conditions with the convenience of never leaving the AxCent® interface. The fully prepared analysis is then initiated, while still in the AxCent® interface, and all numerical calculations are completed using Cadence OMNIS/Turbo CFD. Upon completion, the results of the numerical solution are returned to TurboLink™ and all turbomachinery-specific post-processing is completed within the AxCent® interface.

The Concepts NREC FINE/Agile for Fans truly provides all the tools required to meet the needs at the core of designing fans and blowers.