Mixed flow impellers can be challenging, often requiring multiple set-ups due to the ~45° exit angle. Check out how we utilized multiple MAX-PAC cutting strategies in this collaboration with GROB and Sandvik. The GROB G150 shows off its extremely large travel range and Sandvik’s modular tooling reduces costs and adds flexibility.

Project Summary

Material: Titanium

Stock Size: Ø12” x4.25” (305x108mm)

Machine: GROB G150

Tool List:

Machining Strategies:

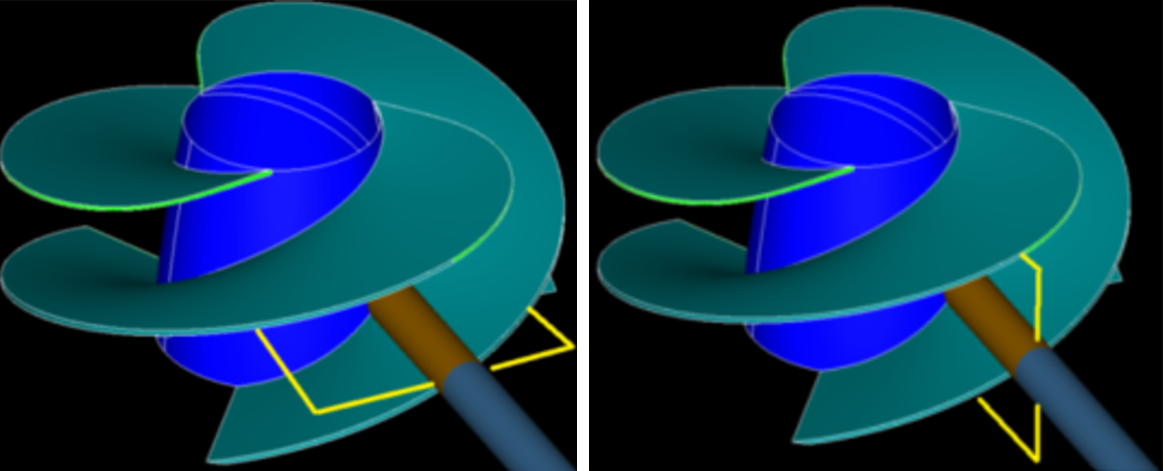

- 3+2 roughing

- Drill through

- 5-axis deep roughing

- 5-axis semi-finishing with box strategy

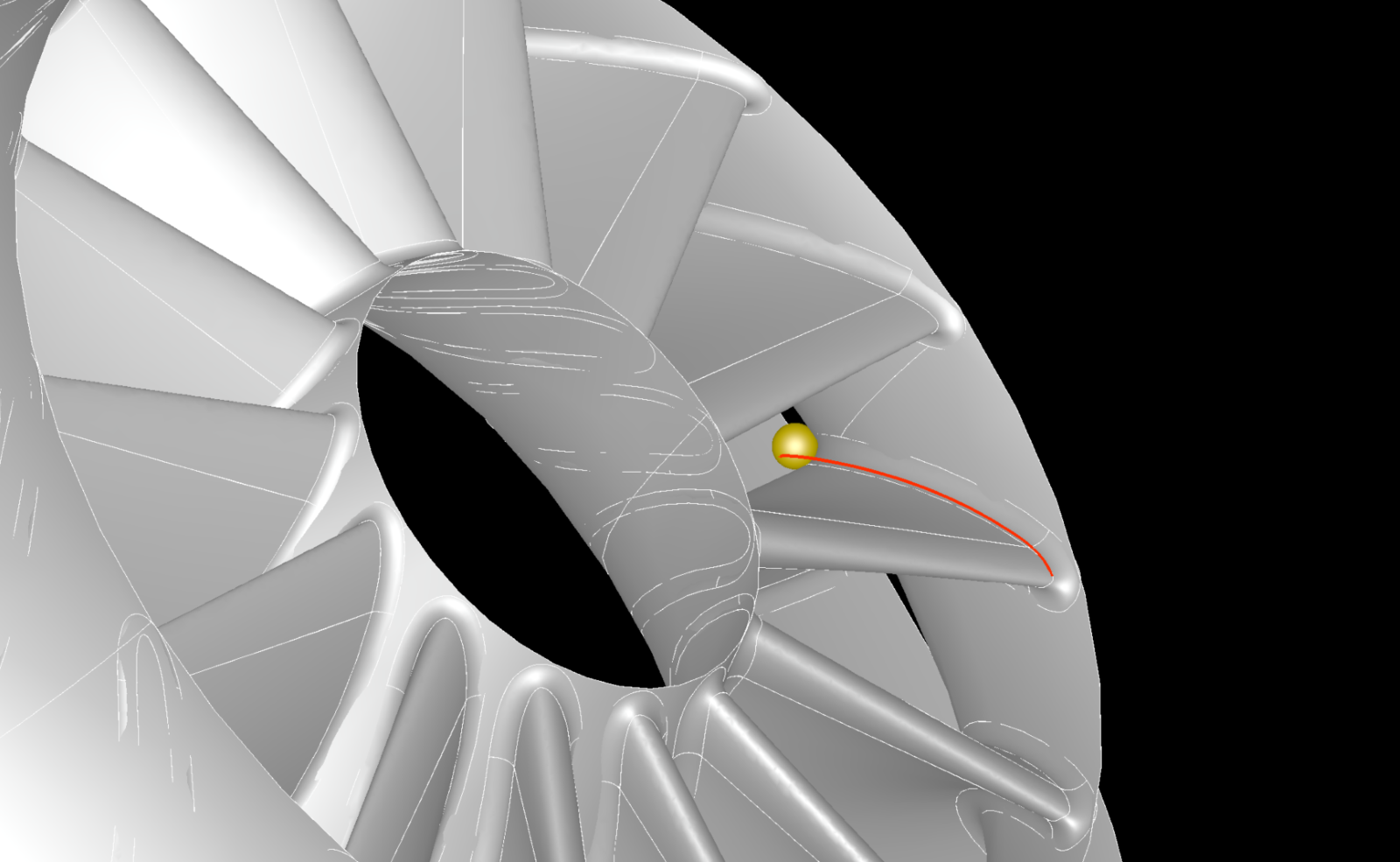

- 5-axis flow line finish

Feature Highlights:

- Safe and fast retract transition within shrouded cavity reduce cycle time

- Collision avoidance includes tool holders, enabling you to safely access positions that you couldn’t otherwise

- Blends between inducer/exducer side yield better part quality

- 3+2 roughing maximizes rigidity for faster roughing

- Part accessibility, A-axis can flip upside-down

- Modular tooling reduces tooling cost

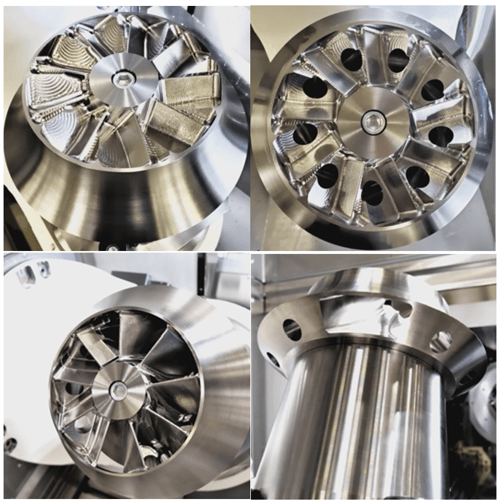

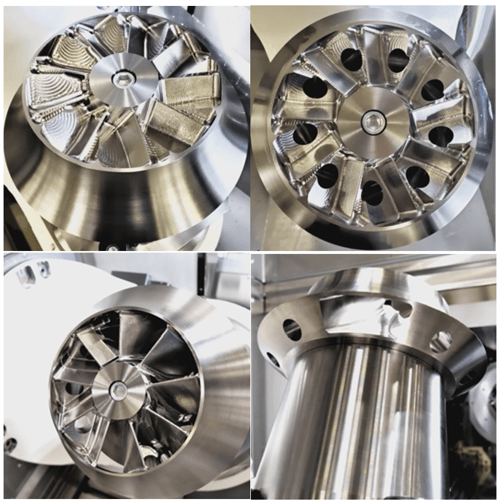

Clockwise from top left: 3+2 roughing at LE, drill through for chip evacuation, view through a finished cavity, multiple cavities in various states of completion

We welcome your questions and comments below, or email info@conceptsnrec.com for further dialogue.