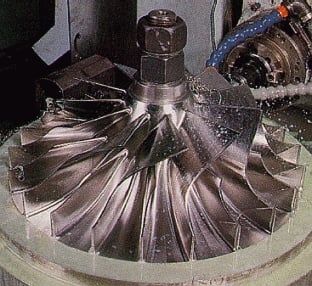

Solving the Tool Orientation Problem for Machining Turbopumps

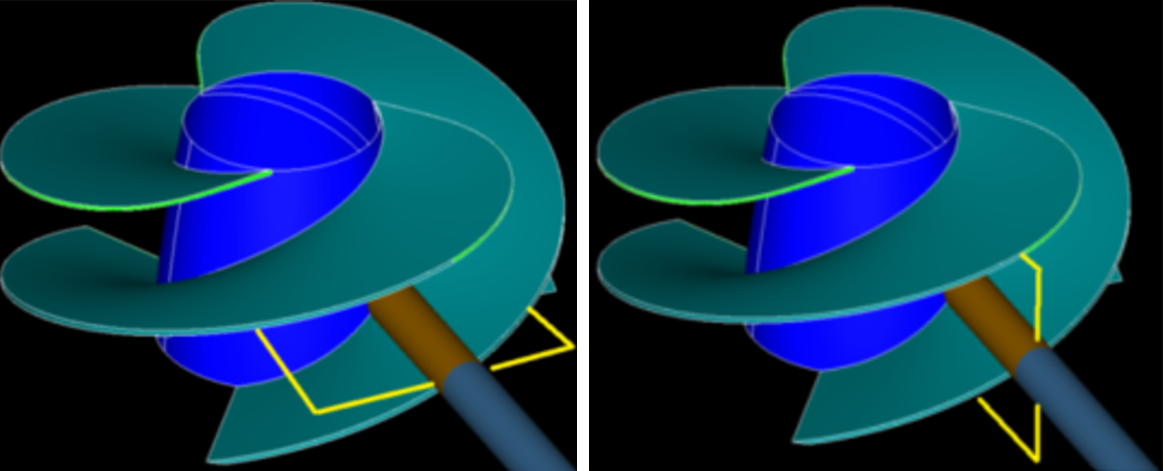

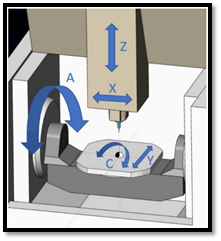

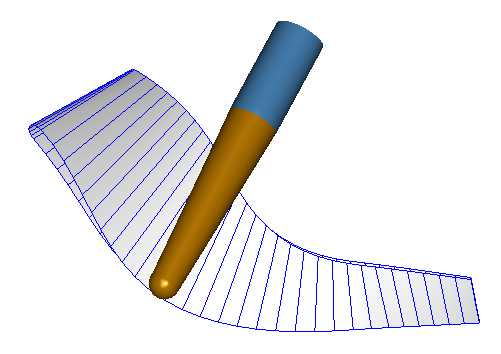

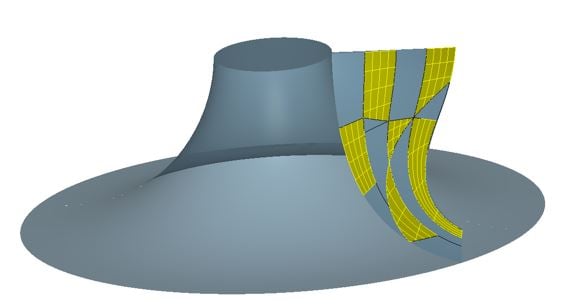

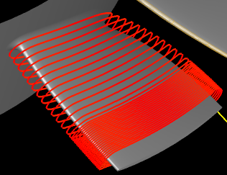

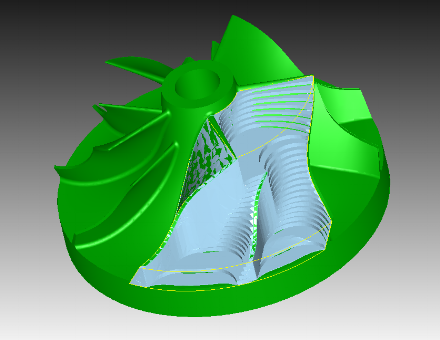

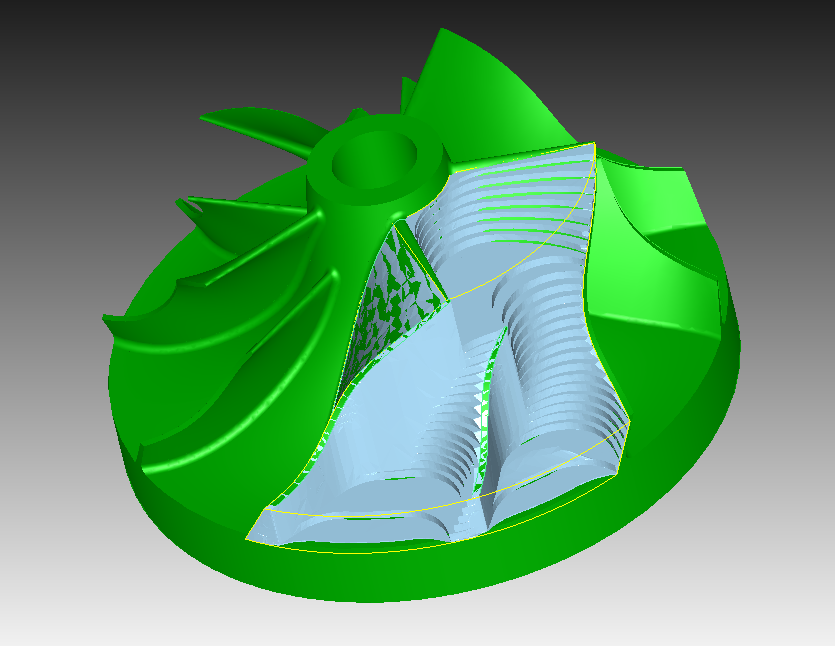

Turbopumps pose many challenges when trying to manufacture high quality CNC toolpaths. They are often made of difficult to machine materials such as Inconel, have sharp leading edges, demanding...