Concepts NREC just had its most successful year ever in software sales. Why? It really comes down to two things, the first is our team, we have some incredibly talented people developing our software and then training, supporting and selling it. The second, is our singular focus on turbomachinery. We are the only company in the world that offers turbomachinery specific CAM and CAE software. We do not try to be everything to everyone and produce machining toolpaths for any product or the ability to analyze anything. We focus on turbomachinery.

Our laser focus on turbomachinery provides many benefits to you. Our software speaks the language of turbomachinery. You do not need to take the time to specify a cylindrical coordinate system, blade and hub surfaces, leading and training edges, etc. The geometrical parameterizations of turbomachinery are already part of our DNA. When you contact us for training or support, you don’t need to explain to us what you are trying to design and how it works. Our experts have decades of experience machining and designing it, so we are ready to step right in and help.

The big players in CAE and CAM are billion-dollar companies who try to solve all problems for all industries. This means that in many cases, a user of these products who is trying to manufacture or design turbomachinery, will need to spend time educating their software supplier on turbomachinery before they can get to a solution to their problem. Not at Concepts NREC.

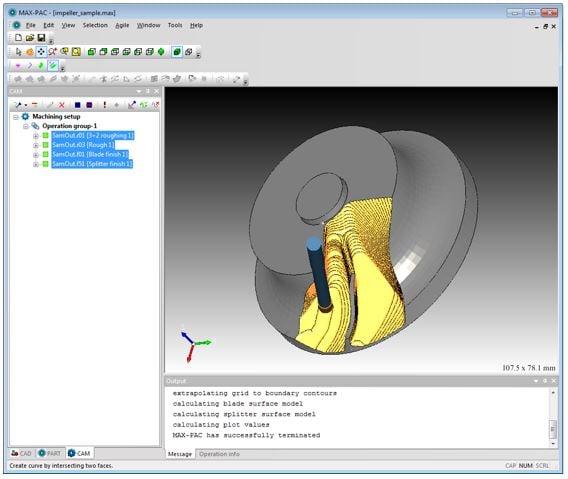

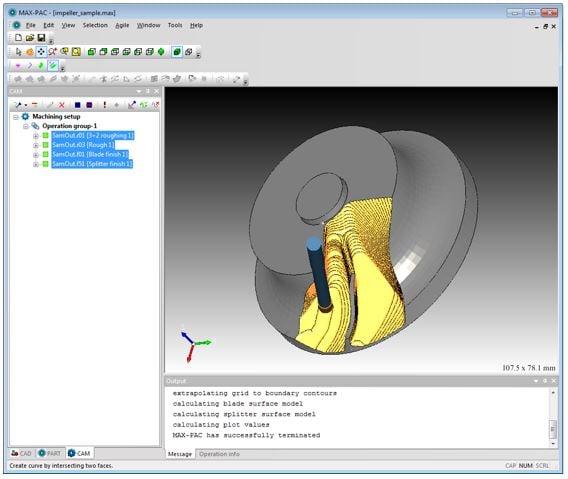

Take for example our recently introduced 3+2 roughing capability for our MAX-PAC family of CAM software. The 3+2 stands for 3-axis roughing at any fixed orientation (the +2). These 3-axis roughing algorithms have been available in general purpose CAM packages for years, so why is it helpful to our customers that we introduced essentially the same thing into MAX-PAC?

The reason is that MAX-PAC already speaks the language of turbomachinery. Our customers already know how to bring impellers and blisks from CAD, or turbomachinery specific design tools like AxCent into MAX-PAC. Now they can add 3-axis roughing without having to bring the same geometry into another system and make sure all the orientation, offset, unit system, rotational direction, etc. are matched up. This is a huge time saver, and also helps to avoid costly errors.

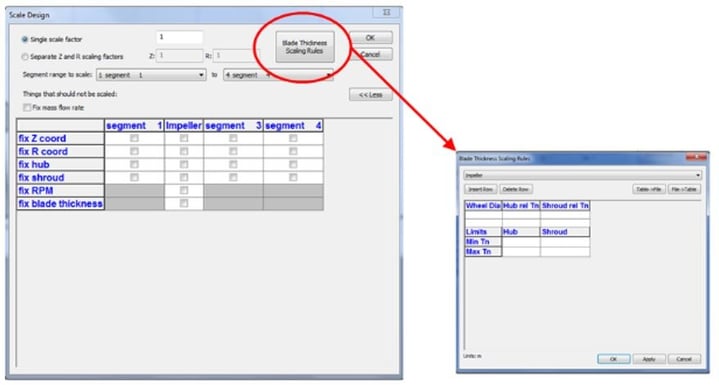

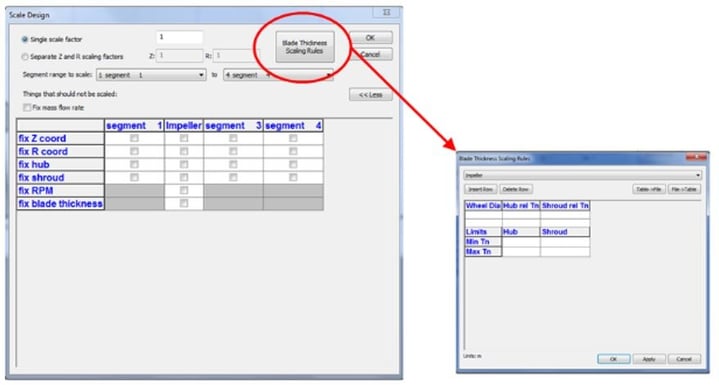

Another example is the intelligent scaling capability in our CAE system. Very often our customers will get a new requirement for a turbomachine that can be met by scaling an existing design. Sure, all of the general purpose CAD tools allow you to scale, but in the Agile Engineering Design System, we know that what you are scaling is an impeller, and oftentimes you do not want to scale the blade thickness in the same way that you scale all of the other dimensions. This is because blade thickness directly effects stress levels, vibration frequencies and manufacturability. By adding some intelligence to allow the designer to scale the thickness with different rules from the other dimensions, we save a lot of time that would be spent doing that with a general-purpose CAD system.

These are just two of examples of how turbomachinery specific manufacturing and design software saves our customers time and helps them to design better products. There are many more.

At Concepts NREC, we have been working in the turbomachinery industry for over 60 years. We listen to our customers and carefully monitor trends in the industry to improve our software every year. Our goal is to make life easier for our customers. Our record-breaking year indicates that we are on the right track. We appreciate our customers business and hope that this year is even better! We have big plans.