Computer-Aided Manufacturing software for turbomachinery generally uses 5-axis milling with some form of collision checking. It is a prerequisite given the expense of the machines, tools and parts involved in the manufacturing process.

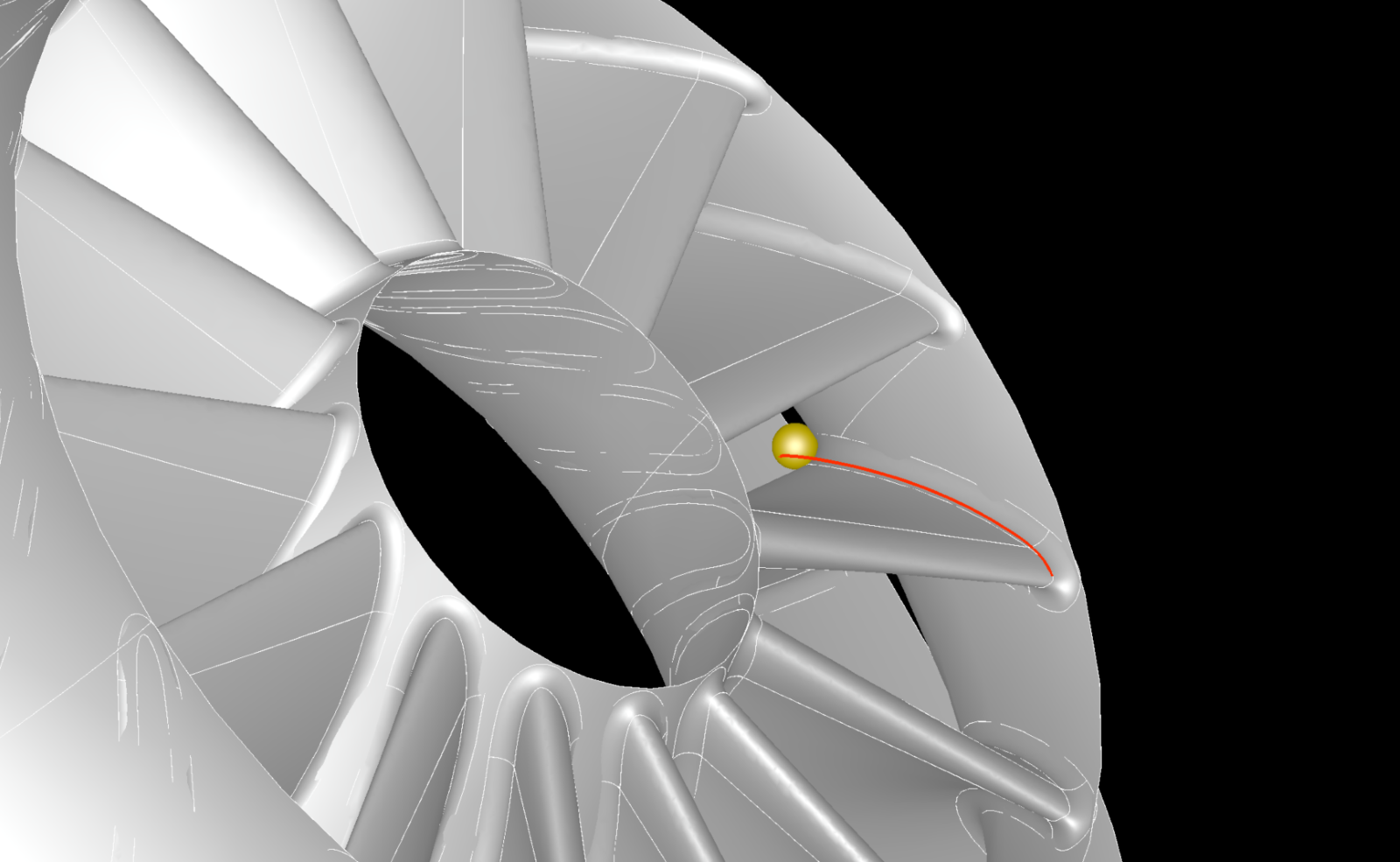

The advantage of 5-axis milling is that the tool orientation can continuously change while cutting, allowing the production of complex shapes in one setup. Many CAM systems drive the tool orientation directly from the part being cut, which seems to make sense, right? For example, to mill a free-form surface you might start with the tool perpendicular to the surface and then tip it a fixed angle. The tool orientation then gradually changes as it moves along the surface. This method works fine with a single well-behaved surface. Unfortunately, if there are any wrinkles in the surface, or if the path traverses multiple surfaces, there is often “jerky” motion during the machining process. Here is a video clip that illustrates that point. Note how the tool flip-flops around the lead and trail edges.

There are many disadvantages to this approach. The unsmooth machine motion gives less accuracy on critical part features such as the lead & trail edges. Often the only way to improve the part quality is to cut slower, adding to the cycle time and cost of the part. The unstable motion also leads to wear & tear on the milling machine. For the toolpath programmer, this approach requires manually checking for collisions and adjusting the tool angle. Finally, the limited ability to avoid collision can make it impossible to cut complex parts.

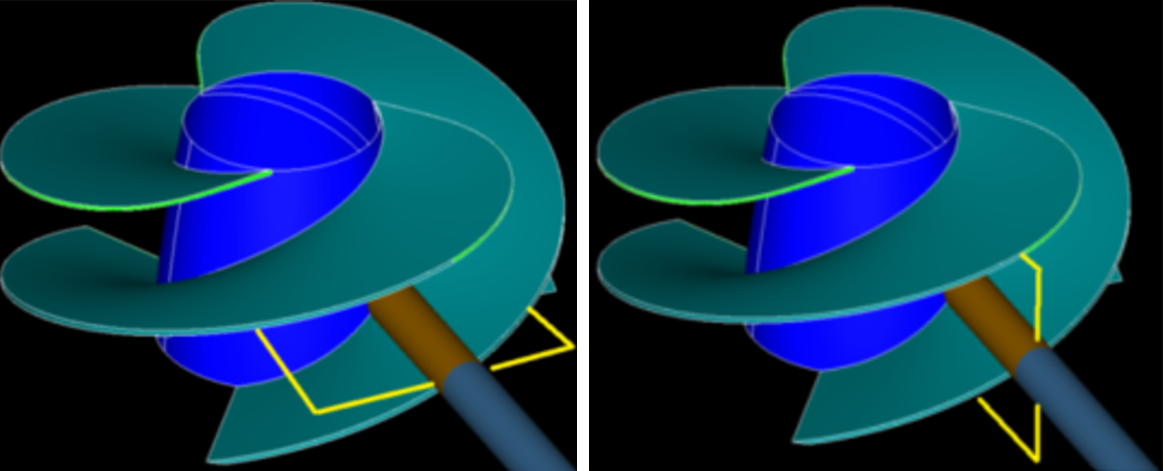

The MAX-PAC CAM system begins with a similar approach, but then uses a patented algorithm that tries various tool orientations to calculate a collision free zone that the tool can maneuver within. The algorithm then determines the smoothest trajectory through that zone. The result is much smoother machine motion, especially as the tool goes around the lead and trail edges. Here is a video that illustrates MAX-PAC’s smooth toolpath on the same part as above.

With smoother 5-axis motion you can cut faster without loss in quality or damage to the machine. MAX-PAC also lowers your overall programming time because it automatically checks everything, such as the tool/holder, and whether or not there is a viable toolpath at all. This means that you don’t have to do a lot of simulations or test cuts. And, you’ll be able to cut more complex parts that are impossible in other CAM systems.

Watching your 5-axis paths run should be mesmerizing, not nauseating. Just like the lyric’s from Sade’s big 1984 hit Smooth Operator, MAX-PAC delivers a toolpath that “moves in space with minimum waste and maximum joy”.

Contact us if you want to learn more. Oh – and sorry for getting that song stuck in your head.