To The Question of sCO2 Compressor Upstream Conditions Selection

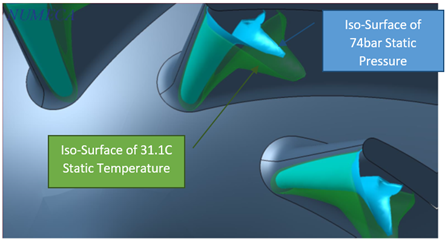

The compressor is generally one of the most sensitive components of an sCO2 cycle. This makes it a challenge to design a robust compressor while keeping the thermodynamic cycle close to optimal.