The Concepts NREC design software solutions are industry-focused, customized bundles of our CAE design products. Unlike general purpose software products, the Agile design suite has been developed by turbomachinery experts, for the turbomachinery industry. Our solutions provide the designer an experience of faster, cheaper, and better turbomachinery design.

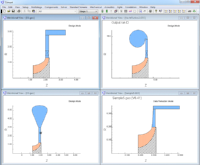

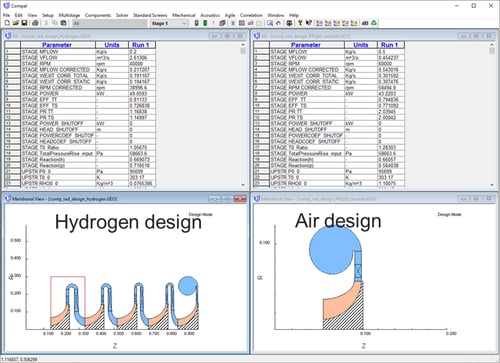

At the meanline level, the wizard-based inputs and rapid 1D solvers simplify the process for achieving an initial sizing of the machine. Performance maps leverage these same solvers through multi-point analysis to investigate the full range of operation rather than just a single design point. The seamless vertical integration between 1D and 3D design through the Agile link eliminates unnecessary solid model manipulation in the design workflow.

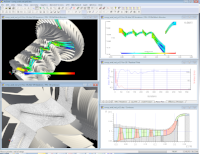

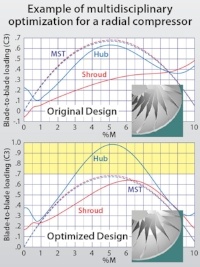

Once in our flagship AxCent® 3D design product, the design can be quickly fine-tuned using pre-defined blade parameterizations and distributions. 2D analysis tools such as multi-stream tube (MST) and throughflow allow real-time visualization of the impact of each geometry modification.

Pre-processing of the 3D CFD analysis is completed without leaving the comfort of the AxCent® design interface. Once ready, the CFD analysis can be directly initiated to run using pbCFDTM, ADS Code LEO, Ansys Fluids and the Cadence CFD product(s). Post-processing of those results can be completed within the AxCent® interface, leveraging custom turbomachinery-specific visualization.

For those looking to truly push the boundaries, optimization solutions are available. Here, a designer can provide design input parameters, objectives, and constraints and leverage the power of an optimization engine. This technique can also be used in a more comprehensive approach to achieve better overall performance for multiple objectives (design points) as well as across multiple disciplines (i.e. CFD + FEA for each design).