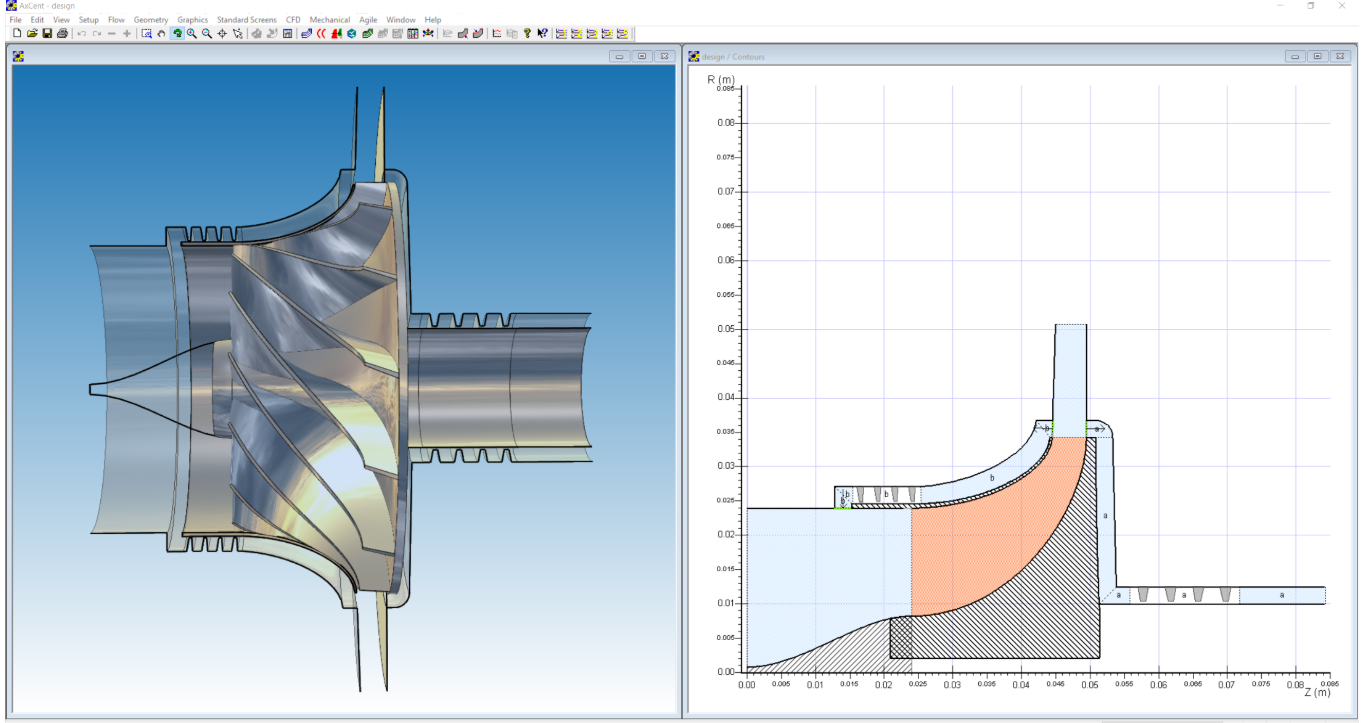

White River Junction, VT, USA – September 2, 2015 — Concepts NREC, the world’s leading turbomachinery design, development, testing, manufacturing and software company, is pleased to announce a major upgrade to its industry-leading MAX-PAC software suite. MAX-PAC CAM tools have long been recognized as the preeminent software for 5-axis milling of turbomachinery impellers, blisks, and rotors. The upgrade features a new user interface and MAX-SB™, a single blade machining module.The new user interface provides an all-in-one view for original CAD model, extracted point grid, tabular data, MAX-PAC milling model, toolpath simulation and post-processing. This new way to visualize the project streamlines and organizes the toolpath programming task which saves time and money.

“Our new user interface was designed to simplify the workflow process. Engineers can slash programming time and eliminate the risk of potential mistakes made while transferring data from one code to another,” said Peter Klein, Director CAM Software and Associate Corporate Fellow at Concepts NREC. “It also provides a lean and clean way for new users to learn the system - reducing training time dramatically.”

“My favorite feature is the new graphical tool library,” said Customer A. “Now I can visualize all of my tools and even build a master library of tools and holders to import for any new part.”

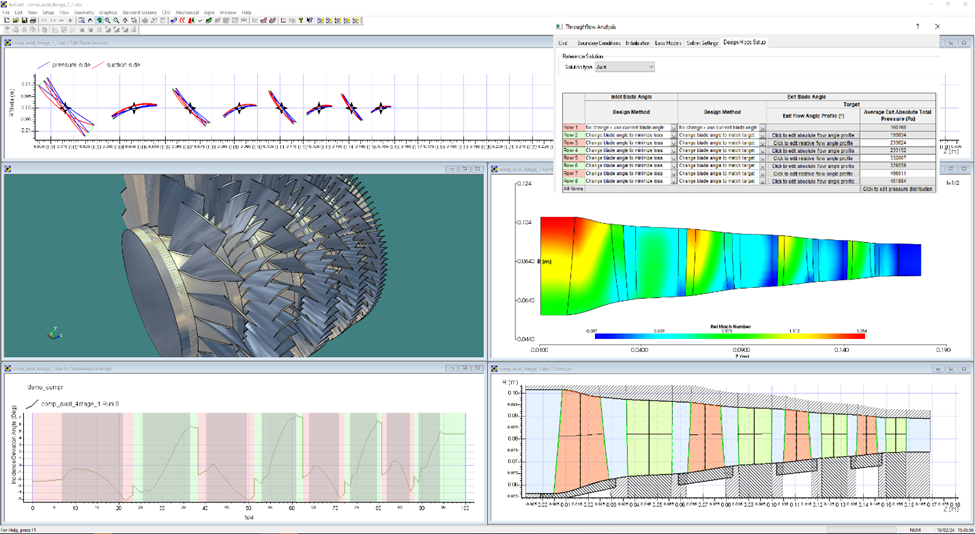

New Single Blade Capability

Max-SB is Concepts NREC’s new product designed for machining single blades. It provides the fastest machining time and smoothest parts with minimal machine accelerations. MAX-SB features a torus cutter for more efficient machining. It has an optimized angle for the smallest cusp and avoids gouging in the concave areas. Both Hub and Shroud platforms are supported.

“While other platforms have had single blade capabilities for a while, we believe our approach to be a major improvement,” said Mark Anderson, Concepts NREC’s Chief Technology Officer. We went out and asked our global customers what was most important to them for their single-blade requirements and then built MAX-SB based on our proven MAX-PAC technology.”

About Concepts NREC

For over 50 years Concepts NREC has been a strategic partner to many of the world’s leading turbomachinery companies. We are the only company in the world that offers a complete in-house solution from initial concept through design, manufacturing, testing and installation.

About MAX-PAC

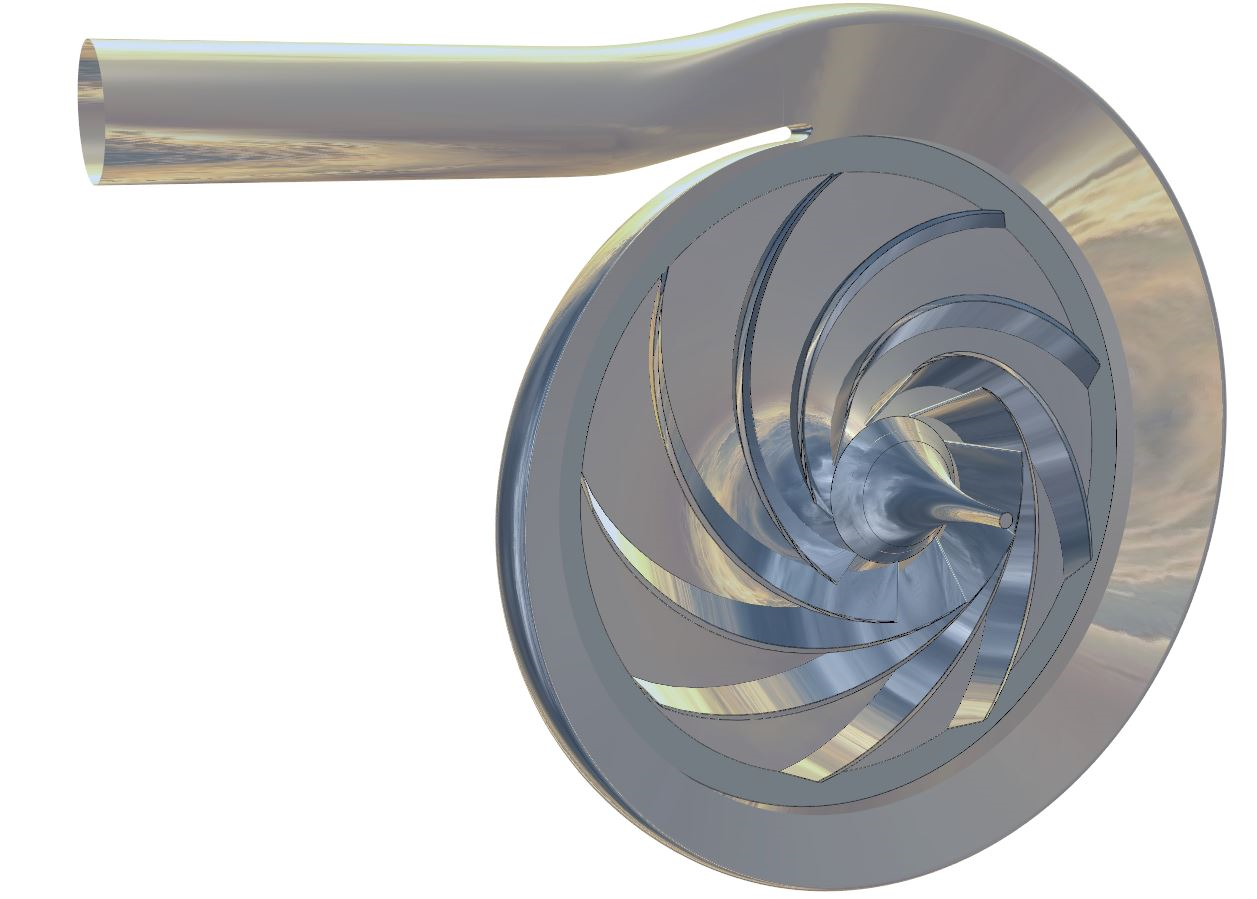

Concepts NREC’s MAX-PAC™ family of CAM software provides optimal cutter-path solutions for turbomachinery components by offering users many cutting strategies that can reduce engineering costs as well as production costs. MAX-PAC addresses only turbomachinery, and as a result, it is faster to learn, easier to use, and requires less programming and machining time. However, its most important attribute is that MAX-PAC produces higher quality parts than its competition.

MAX-PAC is available in any combination of modules to suit part geometry requirements for flank milling of ruled-surface blading, point milling of arbitrary-surface blading, point milling of integrally shrouded impellers or machining single blade parts.

To learn more visit our website at www.conceptsnrec.com