The global health crisis has presented business and industry with uncertainties we could not have anticipated. Here at Concepts NREC, we've worked hard to adapt for the health and safety of our colleagues and for our business. That means, among other things, that I and the majority of my colleagues have been physically separated since early March. I miss them. I miss seeing their faces and those brief hallway conversations-in-passing that later prove to be invaluable learning moments.

So now, more than ever, I wonder what kind of person accelerates their career mid-pandemic and moves directly into a virtual office with fewer opportunities for learning tribal knowledge. Our CAM solutions group recently hired a Product Manager into that situation, so I asked what made him comfortable managing our CAM products for turbomachinery. Meet Jonathan Bicknell.

Jonathan and his Old English Sheepdog Francis at the peak of Mount Moosilauke in the White Mountains of New Hampshire, elevation 4,802 ft.

It is certainly a new experience to start a new job remotely and to meet and work with the team remotely. I believe we all hold a measure of tribal knowledge to give or receive and it simply comes down to being intentional and creative in ways to connect. Whether in the office together or being remote, the one common thread is the intentional work of discovery.

Networking has changed as well, but globally we are all experiencing the same challenges which leads to a natural connection upfront. We are learning new ways to connect, which I know we can build upon into the future. So rather than fewer opportunities I see them as different. We have an opportunity to create and expand our methods of communication and ways to retain tribal knowledge in order to keep pushing forward and build on a strong foundation.

Tell us a bit about your background/education/employment history

While studying mechanical engineering at UVM I had internships at both Concepts NREC and PTC in Boston. I stayed on at Concepts NREC as an Aerodynamic and Hydrodynamic Engineer utilizing the in-house CAE tools to design a wide-range of customer products. This enabled a pathway to relocate to Europe with my family to help grow the business there and advance the technical use of the CAE and CAM Products. I also had the privilege to help launch initiatives in India as well.

In my next career transition I had the opportunity to start a new business called Turbocam Energy Solutions focused on metal treatment for turbine side components in heavy duty turbochargers as well as plasma spray for aeroengine components. This allowed for further development in new technology areas of additive manufacturing in high temperature materials, Industrial IOT, automation and reliability engineering. My recent work included working at a Boston based start-up MachineMetrics where I shaped Industrial IOT products for manufacturers looking to connect directly to machine controllers such as in 5-axis mills for real time visibility, machine health and deep manufacturing analytics.

What made you want to return to work with Concepts NREC and our clients?

CN has been partnering with OEMs to improve the performance and manufacturability of turbomachines for over 60 years. It is unique to see a company with such a history and I am impressed with the longevity in serving their clients. I am grateful to contribute to a strong team as we closely partner with customers in diverse markets.

What will your role be at CN?

I am a Product Manager on the software side of the company and focused on our CAM Products as well as the integration with our CAE Products. I am grateful for the opportunity to split my time between learning about the needs of our customers and working closely with engineers to build the solutions.

What do you see as the strengths of our CAM products?

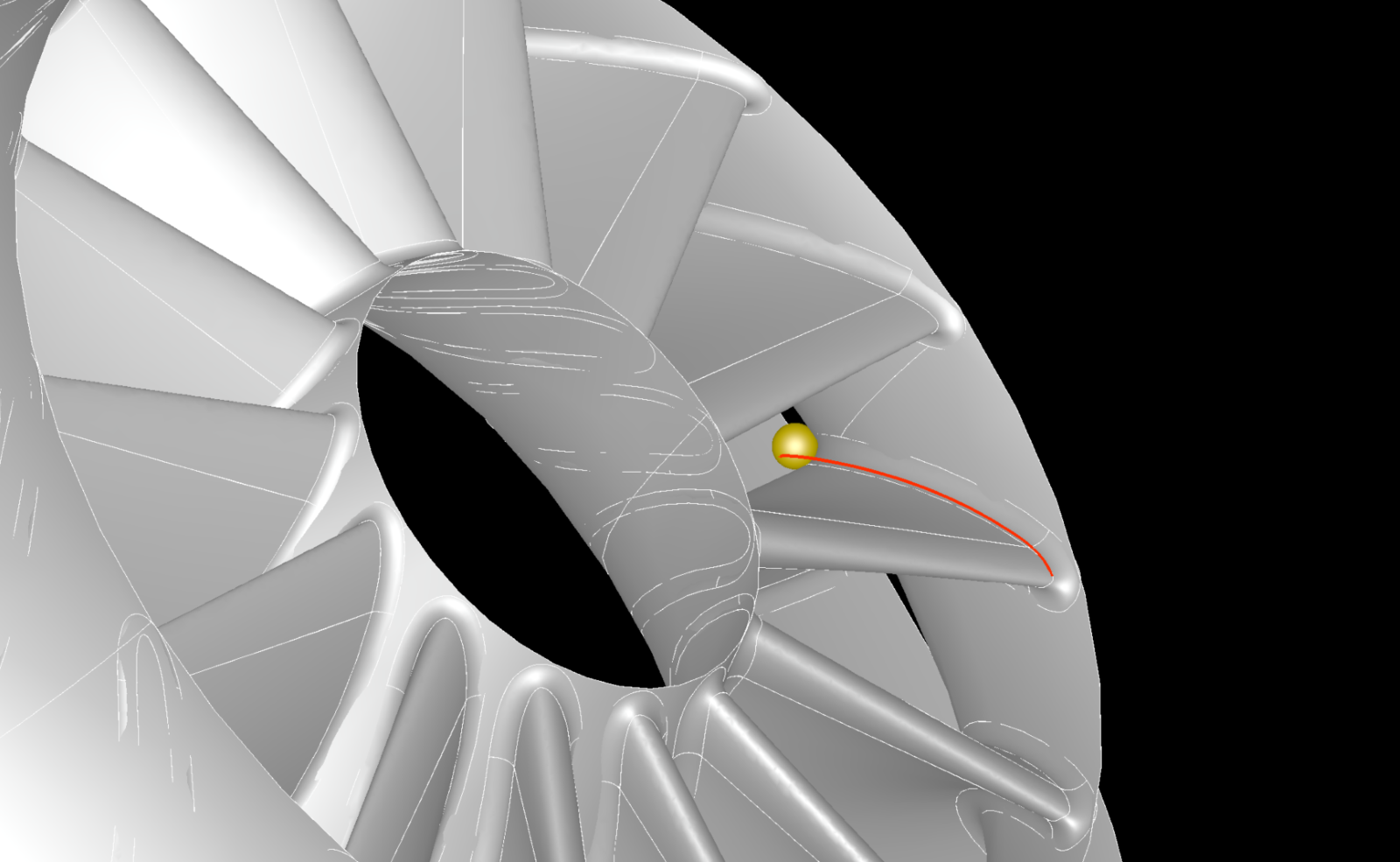

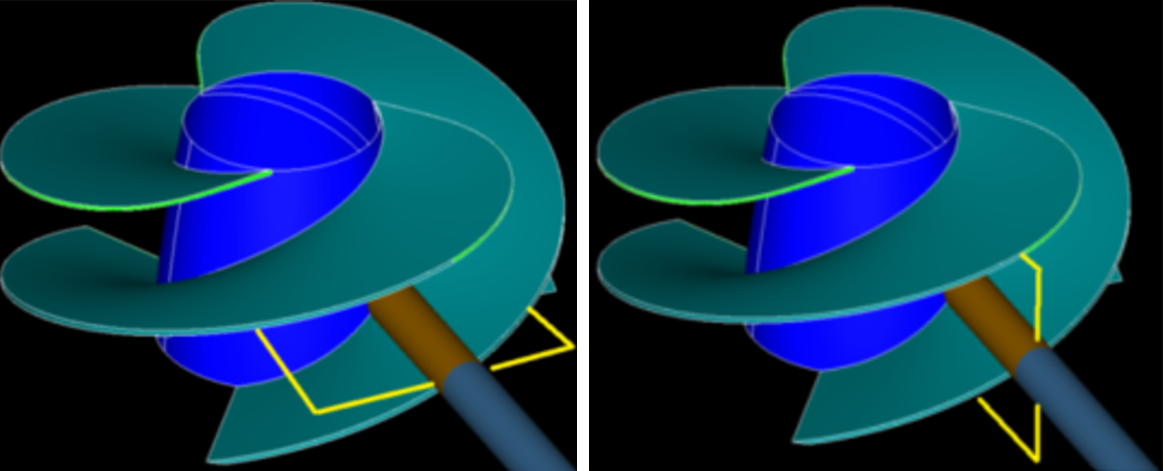

Our CAM products are specialized in handling turbomachinery geometries. This starts with accurate CAD modeling of complex designs and leads to trusted toolpaths aimed to provide the balance of reduced cycle times, tool life and smooth machine motion.

What are your goals and expectations in the role?

Kudos to the CAM team for building a CAM product with a strong foundation and reputation in the market. My hope is that we will continue to serve our customer base well and continue to lead with our CAM products enabling word class machining of turbomachinery components. I also expect to extend our integration with our CAE tools to give quick manufacturability feedback during the design optimization process.