Custom Turbine Generators

Waste Heat Recovery

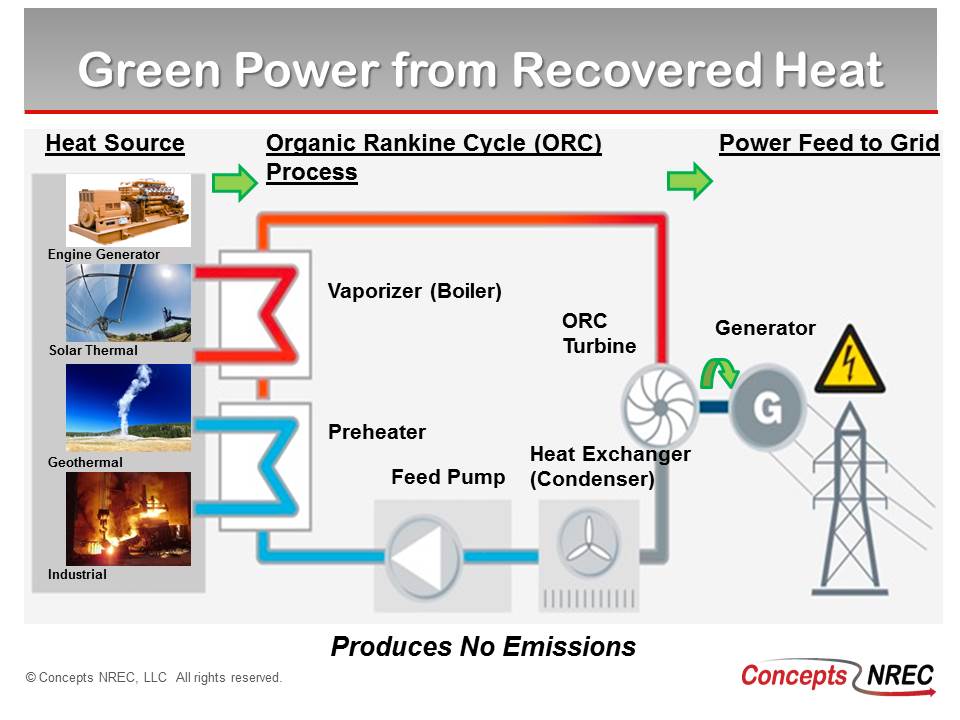

Concepts NREC, with over 60 years of turbomachinery expertise, can create custom compact, high-speed, hermetically-sealed turbogenerators based on customer-specific needs. These turbogenerators are designed for converting low temperature heat to electric power using an Organic Rankine Cycle (ORC) process.

Concepts NREC offers design plans and the intellectual property needed to manufacture your own turbogenerator. To find out more about licensing options, please contact info@conceptsnrec.com.

Increasing concerns for protecting the environment and the escalating cost of energy itself have raised interest in energy conservation to an all-time high. This interest extends to waste heat recovery systems. These systems produce electric power by converting thermal energy to electrical energy. And, when site conditions involve temperatures too low for conventional heat recovery systems, ORC processes become the best solution. These are typically defined as any heat source at temperatures below 800oF. In fact, according to one U.S. Department of Energy report, there could be as much as 1.5 to 2.0 quadrillion BTU/year of heat with temperatures below 500oF available from exhaust gas streams in the industrial sector alone. Naturally occurring heat sources may be just as plentiful.

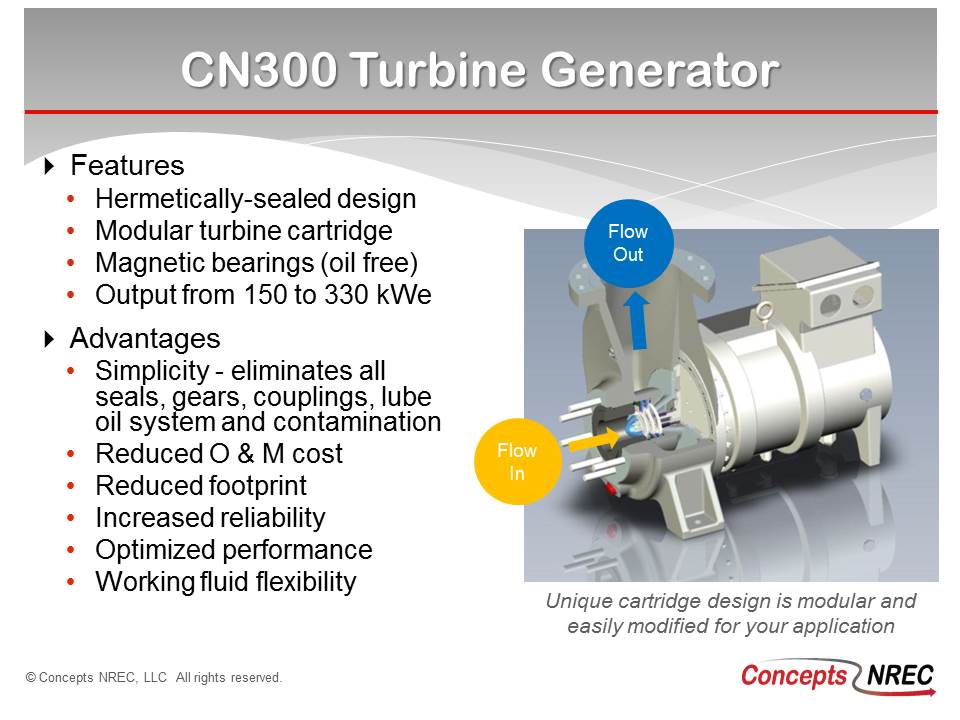

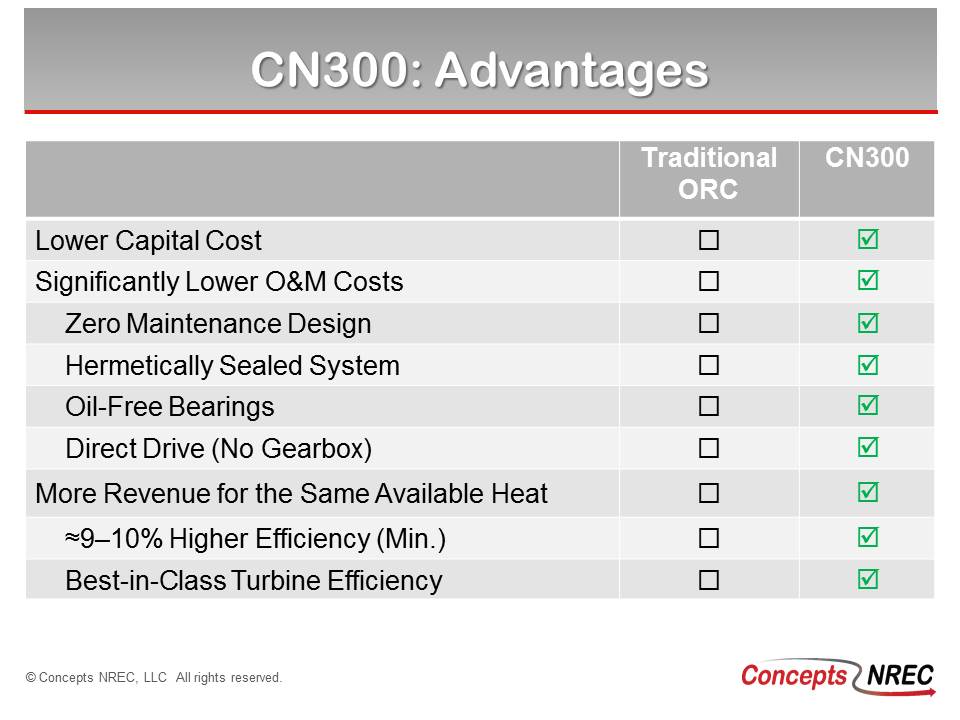

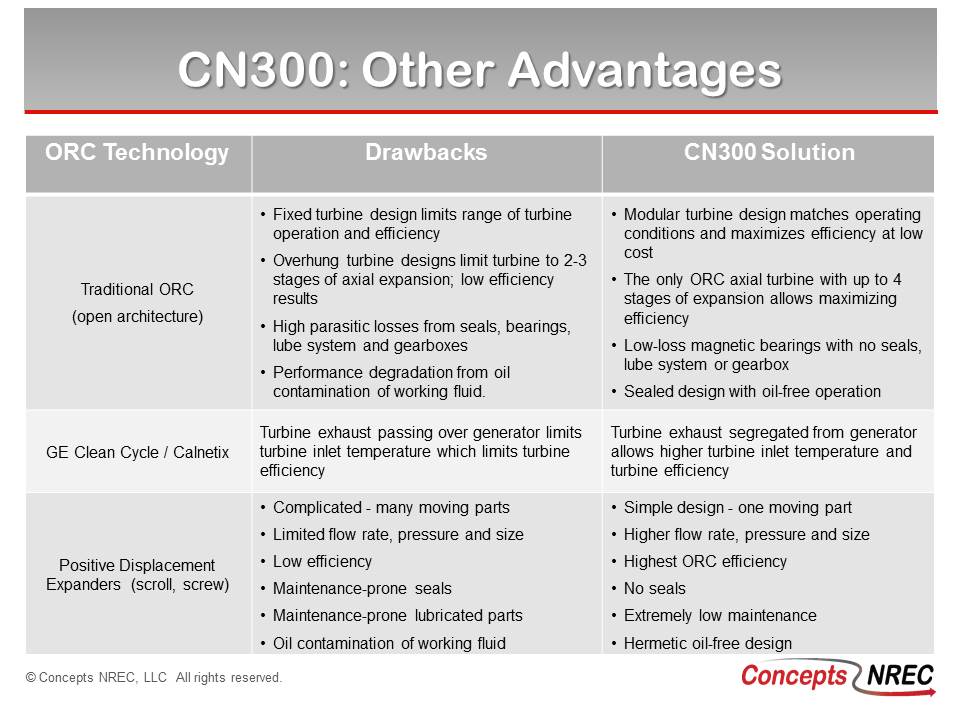

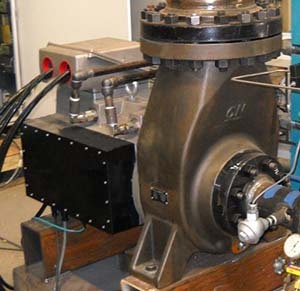

Concepts NREC has developed several ORC energy recovery machines for customers, similar to the one below. The design is a patent-pending, hermetically-sealed design, with an ORC turbine and permanent magnet generator directly coupled that improves mechanical efficiency by up to 10 percentage points over conventional designs.

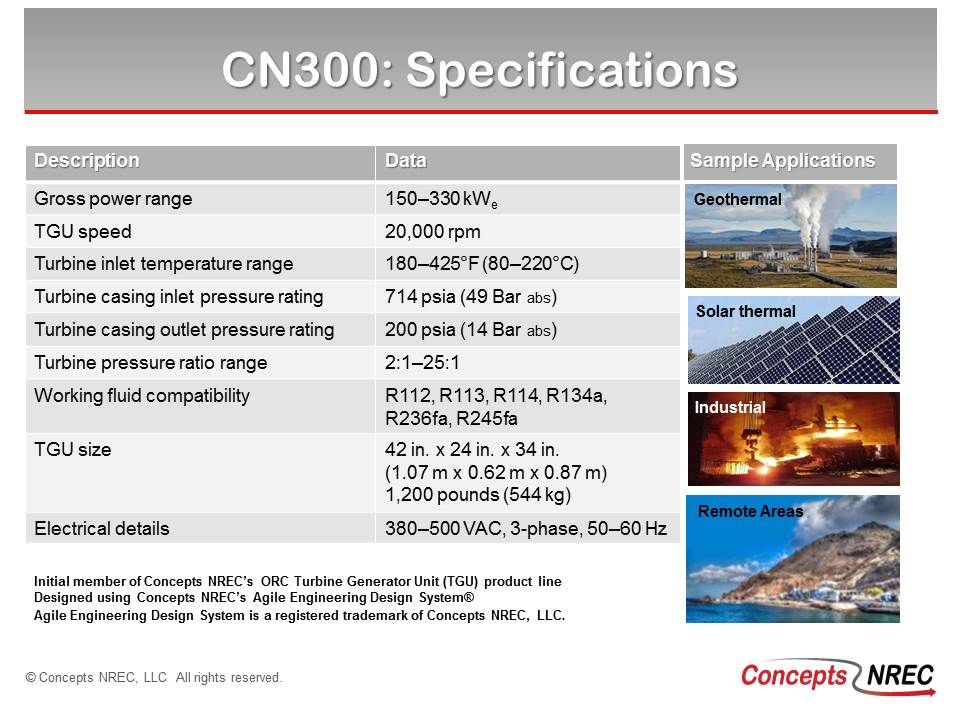

Our turbogenerator is a one-to-four stage, axial, impulse rotor-nozzle design configured in a subassembly cartridge arrangement. With its flexible flow path design, the turbogenerator can generate up to 330 kWe over a wide range of inlet conditions. It can also be customized by changing the aerodynamic shape of the turbine’s stages of rotors and nozzle stators. The basic design can accommodate a wide range of turbine rotor and nozzle cartridges.

By using magnetic bearings, all of the cost, weight, space, interconnecting controls, and general complexity of an auxiliary bearing lube oil system are eliminated. The use of active magnetic bearings also means that the separate vibration probes and/or proximity sensors that would normally be required to monitor gearbox shaft vibration levels are also eliminated.

Our design for a turbogenerator also has state-of-the-art electric generator drive controls. As a result, it doesn’t require an independent, electro-mechanical speed governor to safeguard against turbine over speeding.

This hermetically-sealed turbogenerator also eliminates the need for any shaft seals that keep the organic fluid within the ORC system’s closed loop piping.

With its inherent flexibility, our design offers more power and revenue for a given heat source, greatly reduced operating and maintenance costs, increased reliability, and a significantly smaller footprint than any other ORC turbogenerator available in the world today. To consider anything else for low temperature waste heat recovery systems could be an expensive mistake.

Concepts NREC offers design plans and the intellectual property needed to manufacture your own CN300 turbogenerator. To find out more about licensing options, please contact info@conceptsnrec.com.

Add/replace with shop tour video hosted on Youtube

Capabilities

Concepts NREC’s manufacturing capabilities extend far beyond simply cutting metal. Our highly skilled machinists are backed by experienced design engineers with diverse technical backgrounds and software engineers who have produced industry-leading CAE and CAM programs. This broad expertise enables us to suggest more efficient manufacturing methods, materials, processes, and designs that meet customer needs while lowering their production costs.

![]()

State-of-the-Art Machine Tools and Technologies

Concepts NREC operates a state-of-the-art product center capable of producing the highest-quality, precision-machined turbomachinery components and assemblies. Drawing on extensive experience and expertise with materials, industries, and technologies, Concepts NREC succeeds at complex component challenges that typically have been problematic for others.

This knowledge is supported by the latest manufacturing technologies that, combined, provide Concepts NREC with the credentials to meet the most exacting customer requirements across many industries including aerospace, energy, and industrial processing.

Capabilities

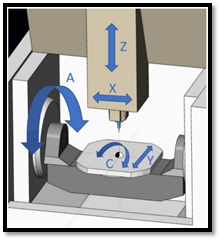

- 5-axis machining of blades, blisks, inducers, propellers, impellers, and other turbomachinery parts

- Component assembly

- Concurrent manufacturing/engineering

- Coordinate Measuring Machine (CMM) inspection

- Dynamic balancing and modal analysis

- Inspection and testing to validate integrity and performance

- Machining complex shrouded (enclosed) impellers for pumps and compressors

- Prototypes and shorter production runs

- Reverse engineering of obsolete parts

Your Trusted Partner

Our design and manufacturing capabilities make us the first choice for many of the world’s leading manufacturers.

- Large OEMs trust us to concurrently engineer/manufacture the blisks and vanes for their newest product designs.

- International pump companies rely on us for our consistent quality and timeliness with their shrouded (enclosed) impellers.

- Users across a broad spectrum of industries leverage our expertise to reverse engineer obsolete turbomachinery parts.

- Early-stage start-ups work with us to build and improve their prototypes.

What We Offer

Capabilities

- Simultaneous 5-Axis up to 39 in (99.06 cm) diameter

- Turning up to 39 in (99.06 cm) diameter

- CMM Inspection with Zeiss Blade Pro for in-depth dimensional analysis of turbine blades

- Assembly & Testing

Services

- Heat Treat

- Wire/Sinker EDM

- Spline/V-tooth/Drive Pins/Polygon

- Grinding

- Abradable Coating

- Brazing

- Polishing

- Shot Peening

- Paint

- Passivation

- Electroplating

- Welding

- Dynamic Balancing

- Overspeed Testing

- Liquid Penetrant Testing

- Ultrasonic Testing

- Laser Scanning

- Additive Manufacturing

Materials

- Aluminum

- Stainless Steel

- Inconel

- Titanium

Part Types

- Pump Impellers (open & integrally shrouded)

- Compressor impellers (open & integrally shrouded)

- Turbines rotors/impellers

- Blisks

- Housings/Volutes

- Bladed stators/guide vanes (IGVs)

- Diffusers

- Shrouds

Tolerances

- Dimensional to +/- 0.0001”

- Surface finishes to 8 µ in Ra

Trust the Experts in Turbomachinery

For over 60 years, we have helped leading global OEMs to improve the performance and manufacturability of their turbomachines.

This is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient.

Below is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient

Below is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient.

Below is a video of Concepts NREC's optional 3+2 Roughing Module that enables roughing out of impellers using 3-axis algorithms, keeping a constant tool vector. This strategy optimizes the toolpath to provide constant cutting load, making it suitable for high speed machining. This is extremely helpful for large (>0.5 m) diameter impellers and/or hard materials where roughing using the 5-axis strategies is less efficient.

Here are some quotes from our Customer Satisfaction Survey sent out after every job:

- "Customer service is really good - they answer questions and concerns in a timely manner."

- "High performance from quote to delivery"

- "Concepts' decision to stock material that is qualified to our specifications is a great competitive advantage. Their willingness to provide technical / commercial informational support makes them my "go-to" supplier for milled impellers."

Agile Products Support (APS)

APS is Concepts NREC’s software maintenance and support program that elevates us from just a software provider to a valued partner.

An APS subscription is included with all annual licenses and is a highly-recommended option for perpetual software licenses. Every software customer is supported for one month following purchase for any installation questions that may arise. Learn more on the Agile Products Support Membership Benefits Datasheet.

- Free software updates

- One business day response times

- Expert technical assistance

- Major discounts on software workshops

- Discounted professional development course

- Annual balloting system for development planning

- Annual Meetings

VAROC® Air Dynamometers

For reliable, low-maintenance load testing of gas turbine engines

Concepts NREC ORC Technical Papers

Development And Testing Of A 250 kWe ORC System Using An Integrated Axial Turbine And High-Speed Generator For 3.7 Bar, A Condensing Steam

Presented At: ASME ORC 2015

Gas Turbine Waste Heat Recovery Using A 20,000 RPM, Sealless, Turbine Generator/ORC System

Presented At: Symposium of the Industrial Application of Gas Turbines 2015

Development Of A 300 kWe Integrated Axial Turbine And Generator For ORC Applications- (Presentation Slides)

Presented At: ASME ORC 2013