Thanks to early pioneering efforts by Dr. David Japikse and his team, Concepts NREC has been at the forefront of turbomachinery design optimization for the past 15 years.

Designing turbomachinery can be a tedious, repetitive process, in which an engineer clicks and drags Bezier points to alter contours or blade angles, hoping, by trial and error, to reach the client design goals.

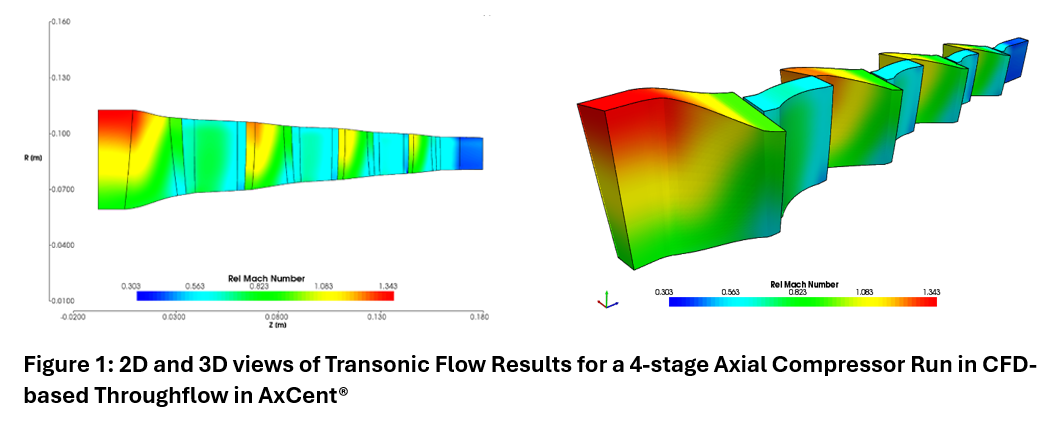

Sometimes the feedback to the engineer can be immediate (seconds), if the streamline curvature analysis tools in a software program such as AxCent® are used. For the best design, however, CFD, FEA, and modal analysis, to name a few, must be used to verify performance and structural integrity. The analyses can take hours to run, requiring the manual designer to configure a new design candidate, and then come back later to see how the new design compares with existing candidates.

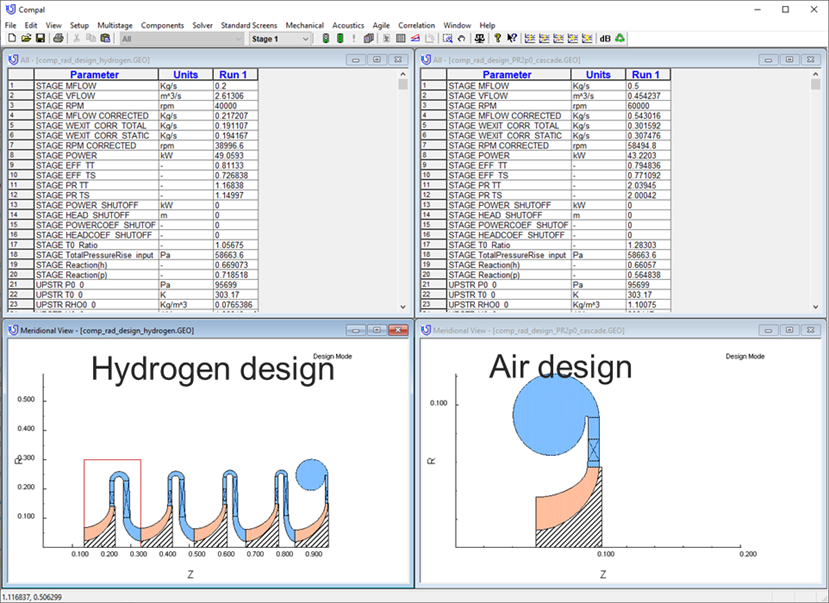

The good news is that much of the design process can be completely automated, running on multiple workstations in parallel or even on the cloud 24/7. The engineer just needs to determine what inputs to the design can be changed and over what range, determine the constraints for performance and manufacturability, and finally the objectives of the optimization, such as improve efficiency.

Once the engineer sets the inputs, goals, and constraints, the execution is completely automatic. Unacceptable designs are eliminated from consideration as the optimizer homes in on an improved design that meets all of the specs. All of this runs 24/7, allowing many hundreds of designs to be analyzed.

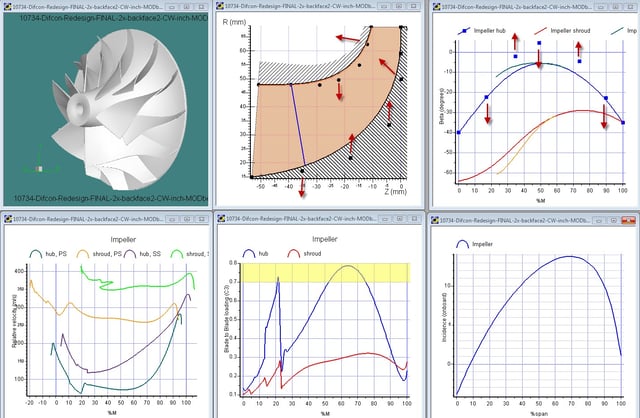

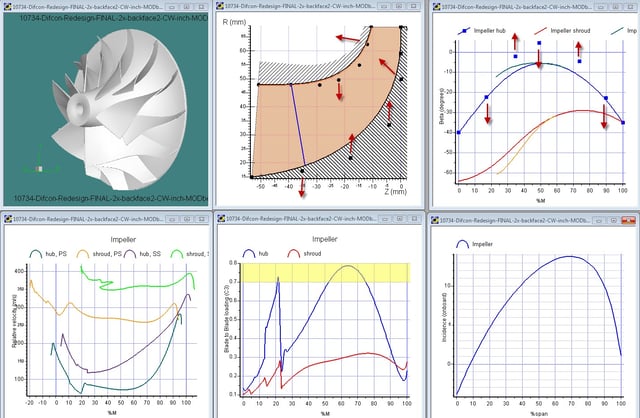

In a recent example, a turbocharger compressor was optimized to improve aerodynamic efficiency, while at the same time, maintaining a design pressure ratio, reducing stress, keeping blade tip vibration within safe limits, and achieving hub separation large enough to accommodate the machining tool used in manufacture. The initial design had unacceptable stress levels and the minimum hub separation was too small. The efficiency was not great. The optimized design increased efficiency by 3 points while maintaining the desired pressure ratio and satisfying all stress and vibration targets. The optimization ran automatically over the weekend on an optimization cluster.

For many years, Concepts NREC has been working with the industry leaders in optimization (Isight, modeFRONTIER, IOSO) to drive Concepts NREC software in multi-disciplinary optimization (MDO). These optimization packages provide access to the latest techniques, including Multi-Objective Genetic Algorithms and neural networks, which can be trained in a manner analogous to artificial intelligence.

Concepts NREC has also partnered with NUMECA International to offer one-click access from AxCent to FINE™/Turbo for the fastest and most accurate CFD for turbomachinery design optimization.