Years ago, I got a pocketknife as a gift, and I absolutely loved it, still do. It came in handy during my college years, when I was really into camping and trekking. As the years went by, it stayed relevant to my new interests, such as motorcycle trips and surfing. It has helped me open cans, remove sea urchin spurs, and install shelves in my apartment. It has also saved me time and money on several occasions by fixing my bike. It is incredible how tightening some screws and pulling some wires can save towing costs – and a sunny day.

The Bike in Question

Man, that pocketknife has some great history. Years ago, I was traveling in Australia with a friend when, after surfing the whole day, we were looking for a place to camp. It was already completely dark and as we drove down this small country road, we passed a van with two guys looking under the hood with their cellphones. We decided to stop and try to help. It was easy to see that the problem was the accelerator wire (which pulls the engine throttle) had broken. I took out my trusty “jack of all trades” pocketknife and after pulling out the rest of the wire, improvising a hook, and reassembling it, those guys were on their way. Another instance when I felt like MacGyver, thanks to my pocketknife.

But, there have been times when my trusty pocketknife has failed me. I remember trying to assemble a whole wardrobe with it. I could have done it, but when I went and got a proper screwdriver, the whole process became much faster and more efficient. The most memorable time was when I tried to use it to make sushi to impress a friend while we were camping. It didn't go well. The salmon pieces looked terrible, like they were ripped apart rather than cut. While my hacked up salmon sitting on top of rice was sushi, it wasn’t very good sushi.

My Pocketknife

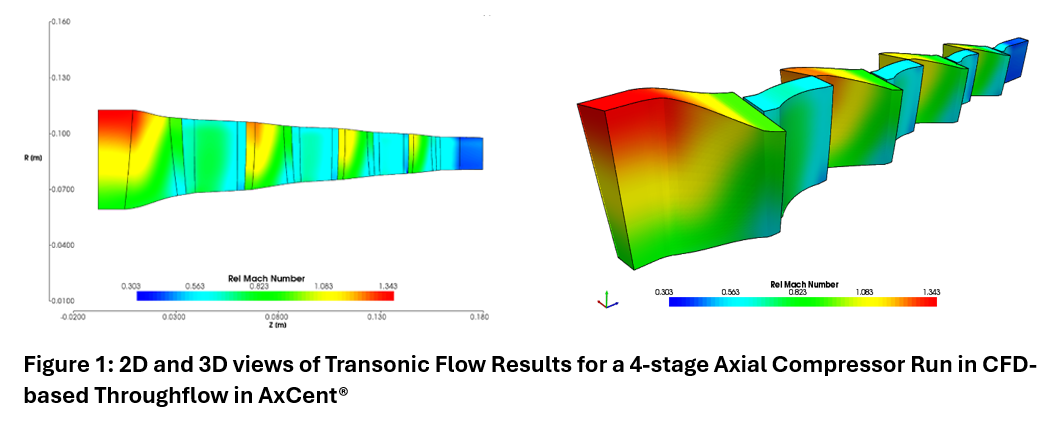

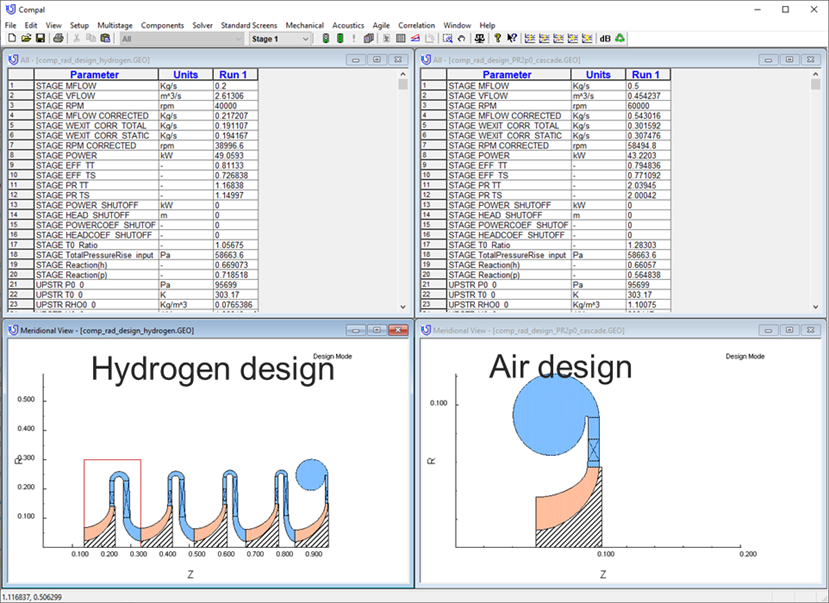

It was another example that specific applications need specific and optimized tools to get the best results. It is not that different in the turbomachinery world. You can do a decent job, designing a part with a multipurpose CAD tool and spreadsheet to calculate initial diameters, throat and other parameters – but it is like trying to assemble the wardrobe; it’s slow going and you might not get the optimal results (I think the scratches on the wardrobe add character).

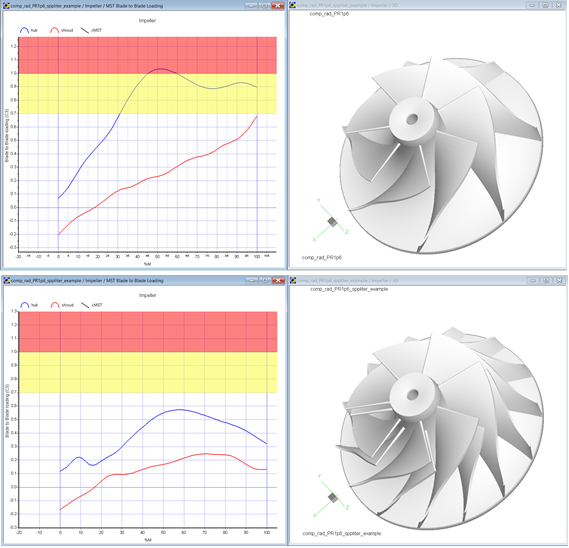

Say you have an initial design for your centrifugal compressor, but your calculations indicate that the blade loadings are too high. What do you do? A typical fix would be to add some splitter blades to your impeller. With the “pocketknife approach” you use your CAD software to try to draw a mini-blade in between the existing ones. Once that is done, it will probably take several attempts to get a perfect axisymmetric copy of it around the impeller. Then you have to rerun your analysis tool. If the analysis tool is a multipurpose CFD, then you will need to re-mesh to run the simulation. We are talking about a 1-day process, at least, just for this one design iteration. And what are the chances that you hit the optimized design on your first try? Zero!

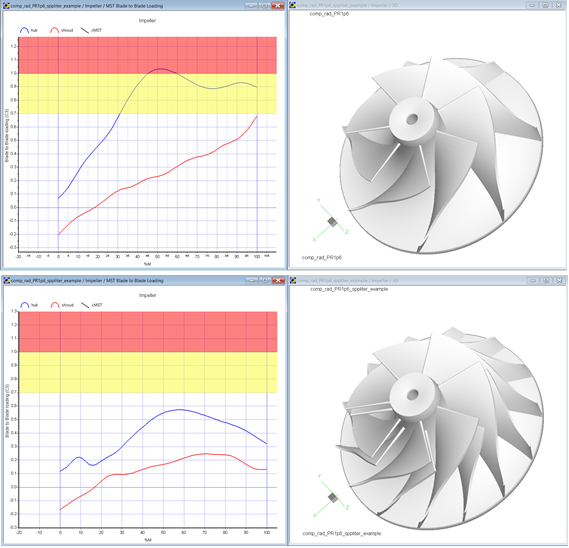

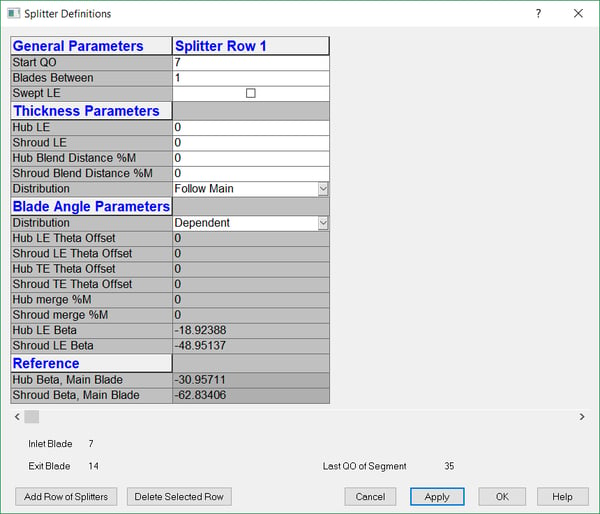

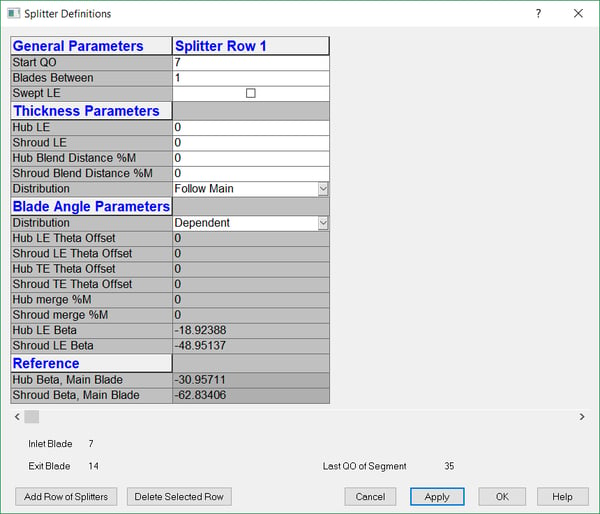

Now, if you are using a software tool that is specifically designed for this operation, like AxCent (our sushi knife for turbomachinery design), you are just 2 clicks away from adding splitter blades. In addition, if you turn on the MST solver, you have a preliminary result of the efficiency of your design iteration within seconds:

Before (above) and after (below) adding Splitter Blades.

Results for the MST analysis for Blade Loading in the left.

Window to easily define and add Splitter Blades

While I still love my pocketknife, I know that this all-purpose tool is best suited for general applications. If I want to get the best results and the highest efficiency, I am going to have to use something specialized for the task at hand. So, whether you are designing a cutting-edge transonic compressor or trying to make a perfect sushi, you should use a specialized tool. That’s how you take your project, and your cooking, to the next level.