The great engineer, Dr. Nikola Tesla, is best known for his work with alternating current (AC) electricity, but, did you know that he patented a bladeless type of turbomachinery in 1913? Called the Tesla Turbine, he developed it while trying to make an engine that was light enough to power his ultimate goal of building a “flying machine”. Tesla-type turbines can also be referred to as multiple-disk, friction, shear-force, or boundary layer turbomachinery.

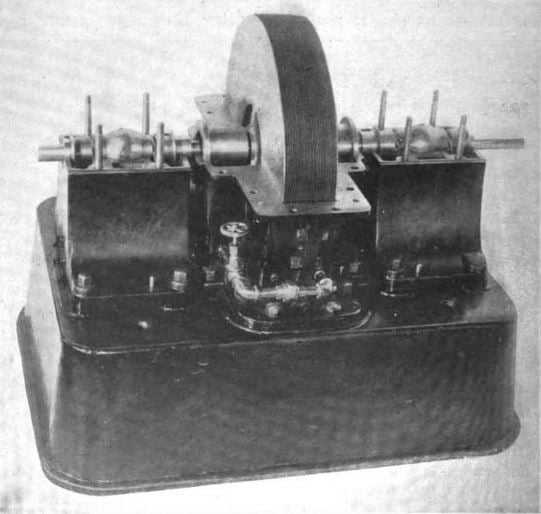

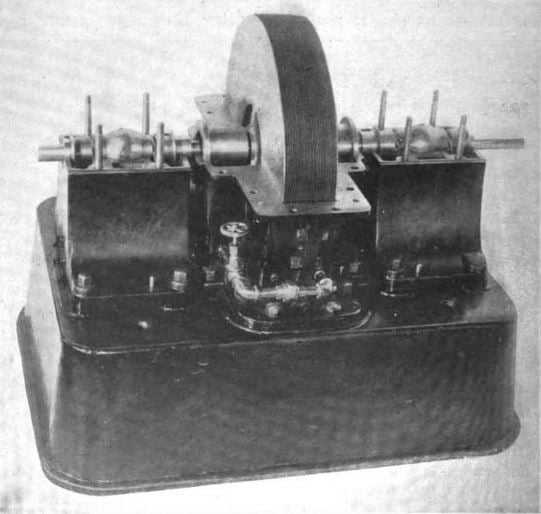

In an article written in 1912, Tesla showed off a small engine that produced 110 hp and was “the size of a derby hat”. The article features the image below to show off how small it was.

It had one stage, ran at 9,000 rpm and had a steam pressure of 125 lbs at the inlet and used 38 lbs of saturated steam per hp hour. Tesla claimed that he could get it down to eight lbs per hp hour with compounding. His novel design used two common fluid properties, viscosity and adhesion, that usually lowered turbine efficiency, to turn multiple flat disks of steel, mounted closely on a shaft.

When used as a turbine, the rotor and disks are enclosed in a housing and the fluid is injected at the edge of the disk through nozzles. The injected fluid spirals inward across the disk, causing it to rotate, thanks to viscosity & adhesion. The fluid then exits out holes near the shaft. If used as a pump or compressor, the fluid is pumped in through the holes near the shaft, spirals outward across the disks. and exits from the rotor into some type of diffuser, like a volute scroll.

Tesla pointed out several advantages of his new design, including simplicity, cost-effectiveness, and serviceability. It could also be run in either direction, pretty cool. During that 1912 interview, Tesla also demonstrated a small pump that was powered by a 1.5 hp electric motor that pumped 40 gallons of water a minute against a 9-foot head.

So, what happened? Why are all the engineers here at Concepts NREC designing pumps and turbines for our customers with blades? Well, the key reason is that the 95% efficiency that Tesla envisioned was never realized. Despite over 100 years of trying, there are relatively few applications for this type of design. Part of the problem is a lack of real data. This makes trying to determine exactly what the efficiency is for a Tesla turbine a bit of a moving target. In 1991, Professor Warren Rice presented a paper on Tesla Turbomachinery at the International Tesla Symposium. His paper explores the research and successful commercial applications of the Tesla Turbine up to that point. Spoiler alert – there aren’t many.

Apparently, despite its relative simplicity, there are some significant engineering issues with the Tesla turbine design. While it works, the efficiencies are not better, and in some cases, significantly worse than bladed designs. The rotor’s efficiency is high, but the losses from the nozzles and diffusers required drops the efficiency significantly. To see it in action, check out this YouTube video. The best applications seem to be with highly viscous or abrasive working fluids. Tesla himself envisioned them being used in capturing geothermal energy. Some interesting observations in Professor Rice’s paper are that this type of design resists cavitation and is very quiet. That made me think of a submarine or aerospace applications, but I could find no references for this type of turbine being used for that. Rice also points out that newer materials, such as ceramics, might make the design more viable in the future.

Well, since I am in the future now, relative to the 1991 paper, I went looking to see if advances in material science, or possibly CFD simulation, has made the design more popular. After some digging, here are the most recent applications that I could find:

Still, that's not a lot of applications. Tesla is quoted as saying that his favorite invention was the Tesla Turbine. So, I throw it out there to all of you engineers – if one of the greatest engineers of all time thought this design was the best thing he ever made, why are there not a lot more applications?

And even though it can be created without the industries #1 design and manufacturing software or manufactured in shops without advanced 5-axis machining capabilities, it seems like there should be more real-world applications. Sounds like a challenge.

For me, Tesla is ensconced in my mind as the person who helped spark my love of science after a field trip in 7th grade to the Boston Museum of Science. It is still the highlight of the museum today, many, many years later.

A presenter at the Boston Museum of Science hosts an educational program called Theater of Electricity which uses Tesla coils and the world's largest air-insulated Van de Graaff generator to demonstrate the power of electricity.