At Concepts NREC we do a lot of projects from ‘clean sheet’ all the way through manufacturing of prototype hardware. In fact, these types of projects are among the favorite of the engineering staff – create what never was, and quickly get to see it produced in hardware and often tested. For these types of projects, we strongly suggest that we complete a ‘scoping study’ as the first phase of the project.

What is a scoping study, and why do you need it?

Clean sheet turbomachinery projects usually start with a set of design specifications, sometimes very basic or sometimes very complete and detailed depending on the client. Whether basic or detailed, these specifications alone are usually not sufficient to tell what a piece of turbomachinery will look like, how it will perform, or how much it will cost to design without first doing some basic calculations and initial layout work. For a given set of specs there can be different ways to approach the turbomachinery layout, and the best approach is often not apparent until this initial work is complete. Often our clients have only thought about aerodynamic performance (perhaps to match a cycle assumption) and have not thought about mechanical design or manufacturing considerations which are a major portion of the detailed design effort for a complete component. In addition to the pure turbomachinery component questions, there are usually questions about related components (e.g., Will you need a gearbox? Do you have a drive motor with sufficient speed and power?) that cannot be answered based on a set of design specs without at least some preliminary engineering calculations for the turbomachinery.

Consequently, we start the full design process with a scoping study to do initial sizing, configuration layout, performance estimates, and also to see basically what the ‘scope’ of the project really is (how extensive the design effort will be, and how hard the design effort will be). These ‘scoping study’ projects are also sometimes called ‘feasibility studies’. At Concepts NREC we use these terms somewhat interchangeably to denote an initial exploratory study, but ‘feasibility’ implies more emphasis on the likelihood that a concept may or may not be workable no matter what stage count or rotational speed or layout you choose, and in the initial study we are determining if further work is even justified.

Scoping studies come in a range of sizes and costs. The most fundamental scoping study includes simple hand or meanline calculations to determine the type of turbomachinery (is radial or axial best?), number of stages (are you more worried about performance over cost?), the physical size (I didn’t realize it would be that big!), the optimal operating speed (whoops, I don’t have a drive motor that goes that fast), and the potential performance level (I assumed 95% efficiency in my cycle, is that too high?). Within these fundamental scoping studies, simple tradeoffs can be done that help determine the best configuration to meet design goals (will performance be better with a gearbox to increase speed?).

Our clients find it very useful to have this type of fundamental scoping study for reasons such as:

-

Initial performance estimates used in cycle studies can be verified and the cycle analysis can also be checked for feasibility.

-

The size and configuration (axial, radial, stage count, rotation speed) of the turbomachinery can be identified, which has a whole series of benefits, including:

-

Making sure the turbomachinery meets any size constraints.

-

Knowing if the rotational speed is doable with respect to bearings, the need for gearboxes, matching to existing drive motors, etc.

-

Getting basic understanding and appreciation of the physical size/configuration of the turbomachinery.

-

Initial insight into design and manufacturing challenges.

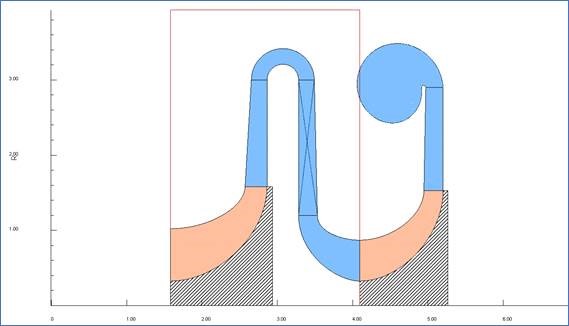

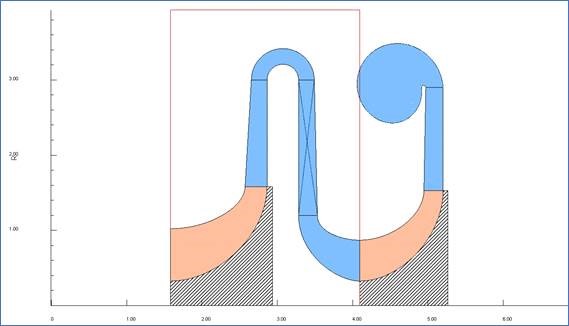

At the end of a very basic scoping study a graphic representation of the resulting aerodynamic flowpath is usually available, and might look like the following example (which shows a two-stage centrifugal compressor, with an inter-stage return channel, and an exit volute):

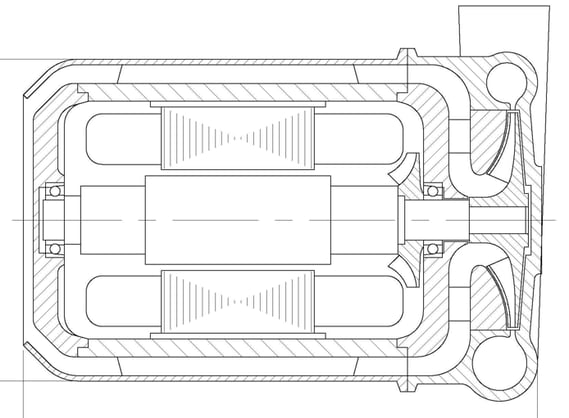

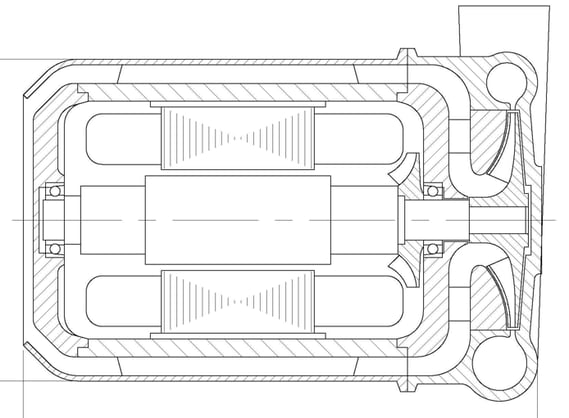

If the initial scoping work shows acceptable results, the next level of scoping study involves preliminary mechanical layout and sometimes preliminary mechanical design analysis. Knowing the general configuration of the turbomachinery from a meanline study, some of the mechanical/structural components can now start to be defined, with the result being a simple 2D cross-section layout of the component, such as the example given below (this graphic shows a centrifugal compressor with exit volute drawing air over an embedded motor, as well as a smaller fan used for additional motor cooling) :

These preliminary cross-sections include at least the major subcomponents (inlets, wheels, diffusers, volutes, return channels, shafting/bearings/seals, and housings). The configuration is preliminary and subject to change as extensive analysis has not been done. In fact, many initial layouts are created from experience and rules of thumb but are still good enough to give the client a sense of what the unit might look like. Critical elements are sometimes analyzed for feasibility in a more involved scoping study. For instance, if the bearing span looks unacceptable, a preliminary rotordynamics analysis might be done to ensure the bearing configuration is workable. The advantages of having such a layout are many and include:

-

Being able to see and appreciate the physical size and layout of the component.

-

Being able to see the complexity of the component, often giving our clients a better understanding of what they are asking for, especially if they do not have a turbomachinery background.

-

Being able to identify areas of risk, from design to manufacturing to operation, which helps in estimating how much work will be needed in detailed design to address these risk areas.

-

Having at least a preliminary sense of the number and type of required parts (and often initial determination of the material choice), which can help when estimating design and even preliminary manufacturing cost and complexity.

-

We have heard several times from our clients that having a tangible, physical representation of the component helps with internal discussions about the project and project planning, and even helps when going to their internal or external funding sources, giving everyone a physical sense of what their money will pay for.

A final and very important outcome from a complete scoping study is having enough detail and understanding of the design and design complexity so that we can accurately cost out the next phase of the design work, providing our clients an accurate quote for the detailed design, and sometimes preliminary estimates of manufacturing cost. Without this level of information, we can only give budgetary estimates for detailed design work or perform the work on a time and materials basis.

We would be glad to complete a scoping study for your project, from a simple study to determine size, stage count, rotational speed and performance, to a more involved scoping study with 2D cross-section showing major components. If you have a project that you would like to get started, please contact us at info@conceptsnrec.com. #turbomachinery #engineering #compressor #turbine #pump