With so many papers out there, I like to pass the word along when a particularly good one comes my way. My favorite paper for 2021 was titled “SELECTING A COMPRESSOR MERIDIONAL TOPOLOGY: AXIAL, MIXED, RADIAL”. A good paper doesn’t just show how clever the authors are (though they clearly are) but it teaches the reader something that they can use in their trade. The lead authors of the paper were appropriately named Smyth and Miller. Not the Smith of the acclaimed Smith chart but clearly inspired by his similar namesake. The two hail from the Whittle Lab at the University of Cambridge.

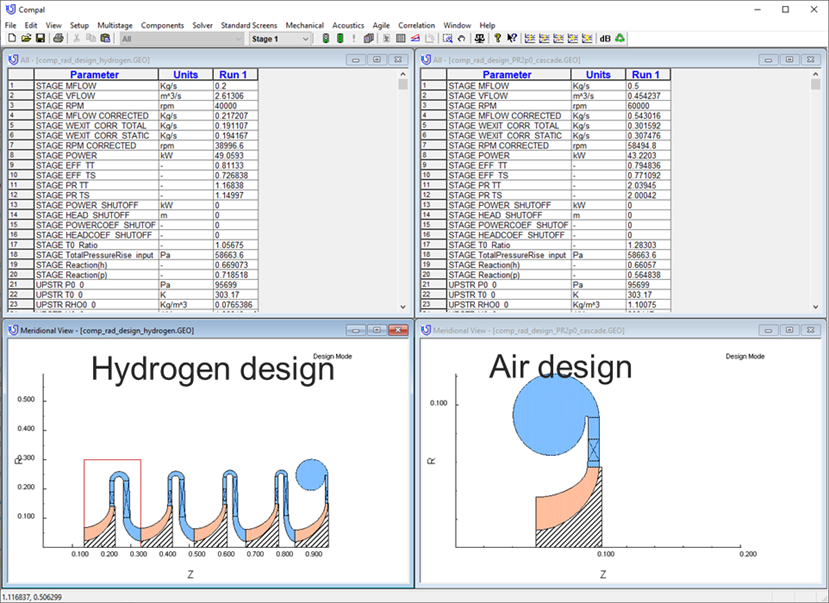

The basic premise of the paper is about finding the design sweet spot in terms of radial, mixed, or axial compressor layout as a function of a flow “duty”. Many papers have been written along similar lines over the years. Different methods have been developed for various types of turbomachinery (pumps, compressors, turbines) and for different classes of design (radial, mixed, axial). They are incredibly useful in getting a starting point for a design, and as such, they are widely used. Useful certainly, but how good these methods really are can be open to question. Some are certainly better than others, but all tend to suffer from three basic weaknesses in my mind:

- Proper selection of correlating design parameters

- Limited datasets the collations are built on

- No consideration of range for the design starting point

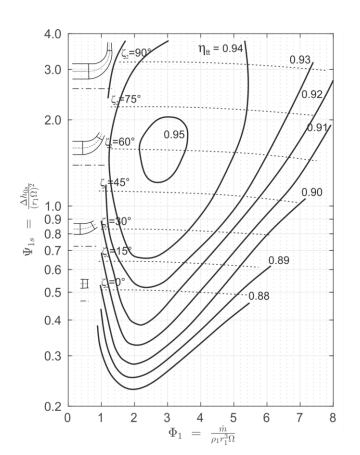

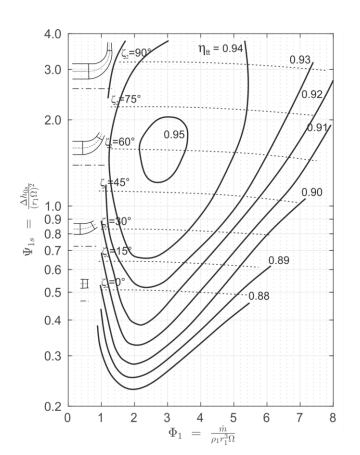

The authors pooh-poohed the usual Specific Speed criteria for radial design claiming it has no physical meaning and is therefore inappropriate to use as a selection criteria. Instead, they refer to a “duty” defined as m1/r1 r3 W , which makes it roughly equivalent to an inlet flow coefficient. I’m not convinced this is the ultimate correlating design parameter (if indeed there is one) but I agree it’s a good one and far more worthy than specific speed. The other correlating parameter is the traditional work coefficient Dh/U22.

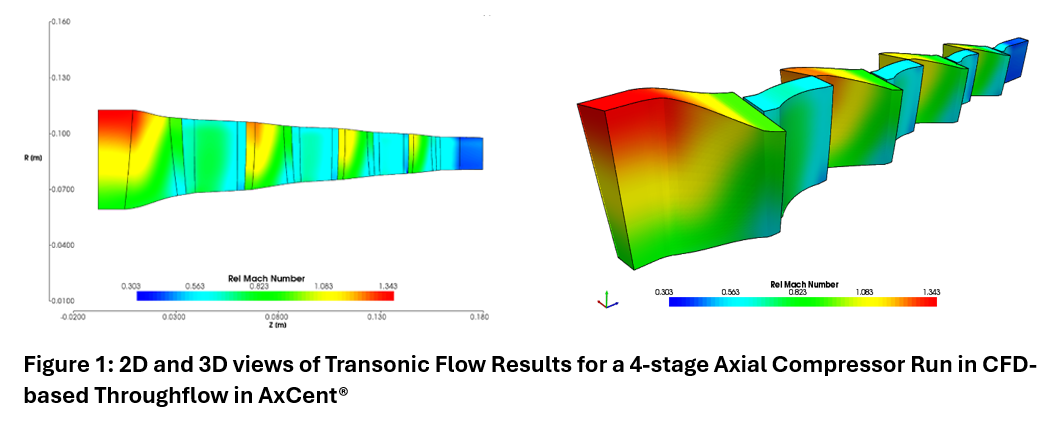

The second potential weakness that was overcome in this paper was the ambitious utilization of CFD to bring statical significance to the conclusions. The authors claim to have made use of more than 6000 CFD solutions. CFD has it limits but these tend to be minimal near the design point and 6000 cases is certainly a significant sampling. This is import, because what works like this (and other Smith chart inspired publications) tell you, is the potential for your design and not what you’re necessarily going to realize. To do that, you need a lot of data to say something conclusive.

Finally, the range question is addressed by finding a balance between highest efficiency and maximum pressure raise by searching a prescribed blade number range. Since the tradeoff between maximum performance and range is a rather subjective criteria anyway, the authors method is as good as any in this regard.

The ideas all culminate in the following figure below representing the maximum possible efficiency at the design point.

Figure from SELECTING A COMPRESSOR MERIDIONAL TOPOLOGY: AXIAL, MIXED, RADIAL, Smyth, Miller, GT2021-59121.

The astonishing thing about the chart is the suggestion that a mixed flow design is the ultimate design choice. Mixed flow designs are not unknown, but they are rare birds in the environment of turbomachinery. I’ve often thought there was a bigger place for mixed flow designs in the world and that they remained rare for no other reason than the fact that so few people know how do them. Still, I never stopped to consider that this class of design might actually be the preferred method. It’s probably premature to throw away all our existing radial and axial compressor designs just yet, but this work certainly makes me want to consider the mixed flow design option in the future.

We welcome your questions and comments here or contact us at info@conceptsnrec.com for further dialogue.