In my last blog, I explored the concept of the flow and work coefficient. In this blog, I will explore the practical application of the two parameters in machine selection and optimization.

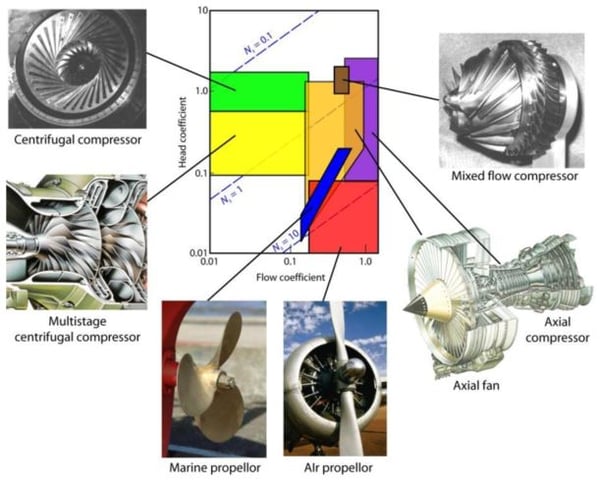

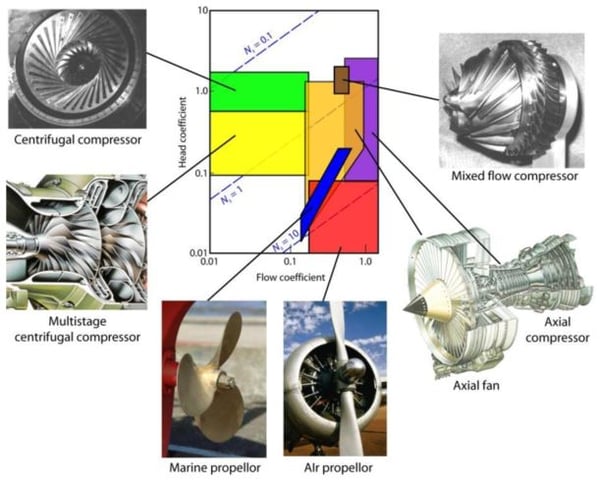

Since there is a wide range of potential flow rates and energy requirements in the numerous turbomachinery applications, different classes of machines must be used, based on the situation. When grouped in terms of flow coefficient and work coefficient, we can see how various machine designs can be applied. The figure below is a plot of energy addition devices (compressors, fans, pumps, propellers, etc.) along with their range of applications.

These radically different design approaches each have their “sweet spot” in terms of where they can be applied for a given flow and work coefficient. It is essential that the right class of machine be selected, since no amount of refinement can make an inappropriate selection perform properly outside its usual range.

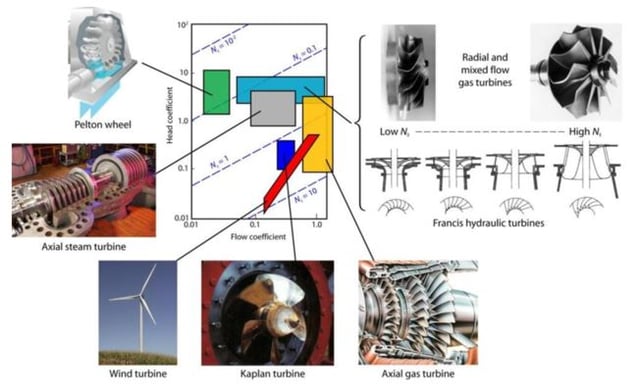

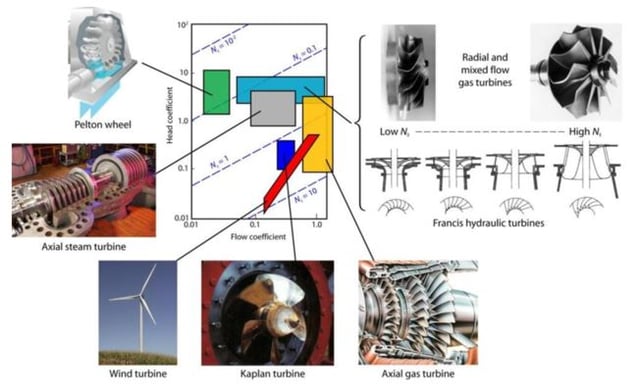

The same principle applies to energy extracting devices, such as the various classes of turbines seen below:

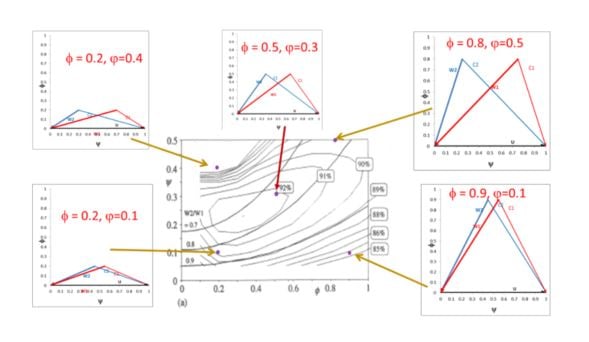

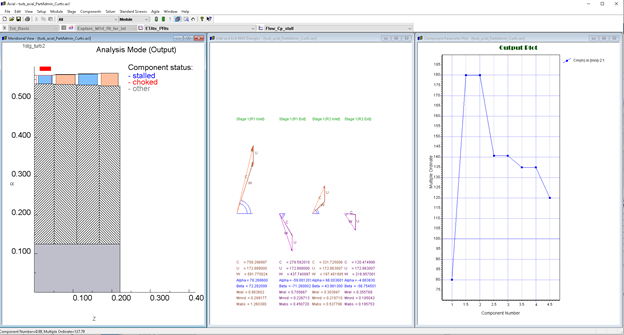

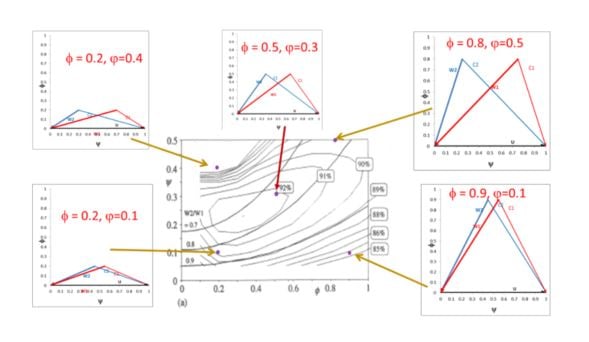

Even within a particular class of machine, there is an optimum region of flow and work coefficient, where performance is generally best. The so-called “Smith Chart” approach has shown this to be the case. By controlling the number of stages, the rotational speed, and machine size, the designer can achieve optimum performance by targeting the ideal location of the coefficients. Below is an example of 2D axial compressor designs and their distribution of efficiency as a function of work and flow coefficient.

Each class of machine has its own sweet spot, in terms of flow and work coefficients, for maximum performance. Because it usually drops off quickly outside this range, it is imperative that the right type of machine is selected to get optimal performance.

Note the actual size of a machine is usually less relevant in terms of performance. It is these dimensionless coefficients that dominate the performance. For this reason, flow and work coefficient are valuable tools in machine selection and optimization.