In my last blog I wrote about visiting a local middle school to give a talk on ‘What is Turbomachinery, and How Does It Work?’ The quiz at the end of the talk was for the students to list all the turbomachinery in their home. I had a few examples in mind to get the list started but was impressed with how long of a list we were able to generate after the students thought about it for a while. Since then the list has grown to include 40 items. I will present those 40 below, but first let me repeat the assignment and the ground rules to see if you can think of more:

- List every piece of turbomachinery in your home.

- Inside and outside (in your yard is OK).

- Positive displacement equipment is OK to list.

- Don’t include turbomachinery in your cars or any vehicle or wheeled yard equipment (that’s another list…)

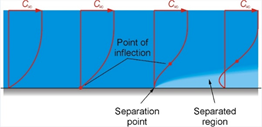

It’s worth repeating the distinction about positive displacement equipment. Here at Concepts NREC we deal with what we consider to be traditional turbomachinery – rotating equipment that imparts or extracts energy to/from a fluid by energy transfer in the tangential or rotational frame via the dynamic action of moving blade rows. Think classical bladed turbomachinery impellers. There is another class of fluid machinery, typically seen in smaller fixed flow rate compressors or pumps – positive displacement equipment– which depends on a change in volume for operation as opposed to the dynamic transfer of energy in turbomachinery. While the operating principle is different, these machines still impart pressure to a fluid and effectively cause fluid to move, so when my middle school students were brainstorming their lists of pumps, turbines, fans, and compressors in their home, I did not exclude or separate out positive displacement equipment.

Without further ado, here is the list with some comments for each entry to briefly explain what it is. If you can think of additional items, please add them in the comment section below and we will append your suggestions to the list.

- Kitchen refrigerator compressor (circulates refrigerant)

- Kitchen refrigerator fan (circulates air in the fridge)

- Kitchen dishwasher pump (pumps water through the dishwasher system)

- Kitchen dishwasher dryer fan (circulates air in the dishwasher during the drying cycle)

- Kitchen oven fan (convection fan – circulates air in the oven for even heat distribution)

- Kitchen range hood exhaust fan (pulls air/smoke away from cooking surfaces)

- Furnace blower (for forced hot air systems, circulates hot air through your house)

- Furnace pumps (for forced hot water systems, circulates hot water through your house)

- Air conditioner compressor (circulates refrigerant)

- Air conditioner fan (blows air over the refrigeration coils)

- Microwave fan (circulates air to cool internal electronic components)

- Outdoor water well pump (pumps water from your well to your house)

- Swimming pool filter pump (circulates pool water through your filter)

- Swimming pool aerator pump (in hot climates sprays water into air to cool the pool water)

- Outdoor hot tub pump (circulates water)

- Indoor whirlpool tub pump (circulates water in a whirlpool/jacuzzi type tub in your bathroom)

- Clothes washer pump (circulates water in your washing machine)

- Clothes dryer fan (circulates air in your dryer)

- Bathroom exhaust fan (exhausts air from your bathroom to outside)

- Air circulation fan (like you might have in your living room in the summer to keep cool, perhaps a pedestal mounted oscillating fan or a window fan)

- Whole house exhaust fan (a favorite here in Vermont, pulls cool evening air in through windows, exhausts into your attic and then through vents outside, cooling the house/attic after hot summer days)

- Ceiling fan (like the ‘Casablanca’ fan you might have in your living room or bedroom for those hot summer days)

- Radon exhaust fan (not uncommon to many of us in New Hampshire that have home radon mitigation systems that pull radon ladened air from below the house foundation and exhausts the air above the house)

- Vacuum cleaner (whether you have an upright, canister, or robot to clean your house, they all use a suction blower of some type to create a vacuum and move air though a filter)

- Air purifier fan (fan that blows air over filters, often HEPA filters)

- Shop/work bench air compressor (used to supply pressurized air to shop tools)

- Tire air compressor (variation on the shop compressor, used to pump up the pressure in your tires)

- Fish tank filter pump (circulates tank water through a filter)

- Fish tank aerator/bubbler compressor (bubbles air through your fish tank to oxygenate the water)

- Electric heater fan (fan to circulate air through small electric heaters to heat a room in your home)

- Hair dryer fan (fan in a blow dryer for drying hair)

- Fireplace insert circulation fan (another favorite here in Vermont – circulates air through your fireplace insert or stove to increase the heat transferred to the room)

- Basement sump pump (pumps unwanted water from your foundation/basement to outside)

- Computer fan (fan in computers to cool the electronics and power supply)

- Leaf blower fan (fan that blows air to move yard debris)

- Chain saw fan (if you live in Vermont you need a chain saw, and most have fans that cool the engine)

- Yard oscillating sprinkler turbine (some sprinklers have a water supply driven turbine that causes the sprinkler to oscillate)

- Yard rotating sprinkler (some whirling or rotating sprinklers have arms that discharge water tangentially to make the arms rotate and spray the water over a circular area)

- Fountain pump (water pump for your outdoor fountain/display)

- Lawn irrigation pump (in some areas of the US separate pumps are used for watering grass or plantings)

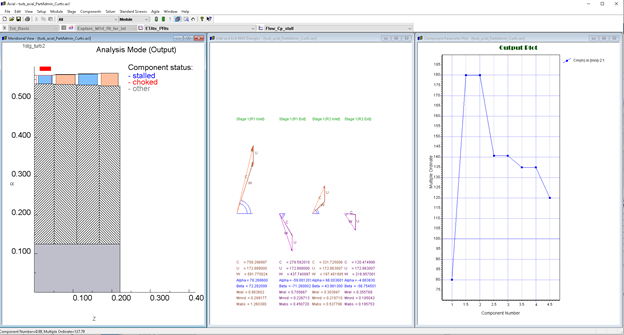

Here at Concepts NREC we have a wide range of experience in turbomachinery design and have worked on projects to design several of these various types of turbomachinery. The fundamental principles of turbomachinery design apply to each and every one of these examples, but different industries often have their own approach to design/optimize the specific components and their installation. If you want to understand more about the basic thermodynamic and fluid dynamic principles that apply to designing any of these turbomachinery examples, considering attending one of our ‘Turbomachinery Core Fundamentals’ courses offered twice a year. If you want to better understand how specific components are designed, we have several appropriate courses including ‘Centrifugal Compressors’ and ‘Centrifugal and Axial Pumps’. Click here to see our full course lineup or contact us to develop a custom course for your company. And if you need assistance with any turbomachinery project there are a variety of ways we can help, providing you with the tools and training to do the design work, to completing design and manufacturing projects for you. Please don’t hesitate to contact us to see how we can help.

#turbomachinery #engineering #compressor #turbine #pump #fan #blower