PUMPAL™

CAE Software for Axial and Radial Pumps

A meanline approach is used to design centrifugal pumps and mixed-flow pumps with single and multiple stages. PUMPAL is used to design the stage, analyze performance, refine the parameters with data reduction, and model the machine according to several performance models. PUMPAL's unique Design Wizard leads the user through all the necessary steps for design, analysis, and data reduction. The meanline pump design can easily be sent to the AxCent®program for further blade design and fluid dynamic analysis.

Components Supported by PUMPAL:

- Inlet guide vanes

- Open or closed impellers

- 2D or 3D impellers

- Front and rear seals (multiple)

- Diffuser types, including…

- Arbitrary vaned

- Vaneless

- Wedge/channel

- Cascade

- Conical

- 90/180 degree bends

- Exit elements, including…

- Collector

- Volute

- Return channel

- Various leakage paths

- Multistage pumps

Modeling

PUMPAL supports two-elements-in-series (TEIS) rotor diffusion modeling, two-zone loss modeling, radial and axial stator diffusion/losses, volutes, inlet cavitation, disk friction, exit mixing, cavity leakage, and more. PUMPAL uses the same consistent model of the stage performance for design, analysis, and data reduction modes.

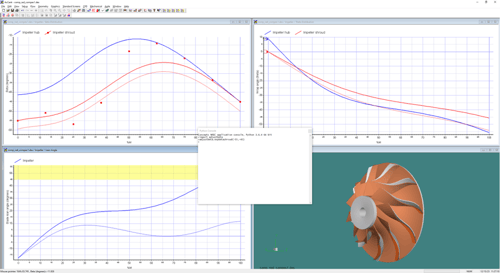

Integrated Performance Map Plotting

Review design performance, analysis, and test data with flexibly plotted performance maps, updated automatically with each geometric change.

Easy Editing

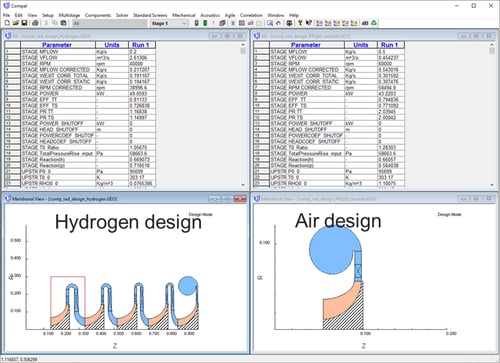

View the pump stage in an active, true-scale meridional view. Edit the parameters by double clicking on the component in the meridional view. Parameters can also be edited using a single text input/output file, a feature especially useful for optimization.

Tabular View of Results

View the results in a flexible, spreadsheet-like table format, customizable through separate filters. Create any number of filters, select what to display, and customize the labels as well.

Axial View with Inlet and Exit Velocity Triangles

Using the window view, view blades and velocity triangles at the impeller inlet and exit. View inlet velocity triangles for the hub, tip, or RMS radius, and exit velocity triangles for the primary and secondary zones, and mixed-out state.

A Real Fluid Program

PUMPAL calculates Real Fluid properties using a variety of equations of state options.

Direct Integration with AxCent®

Start AxCent automatically from PUMPAL, with the initial meanline geometry transferred automatically to AxCent. Changes in AxCent that affect the meanline analysis will cause the meanline analysis to be rerun and all performance maps to be regenerated.

Software Highlights

2020 Release Features

Components Supported by PUMPAL

- Inlet guide vanes

- Open or closed impellers

- 2D or 3D impellers

- Front and rear seals (multiple)

- Diffuser types, including…

- Arbitrary vaned

- Vaneless

- Wedge/channel

- Cascade

- Conical

- 90/180 degree bends

- Exit elements, including…

- Collector

- Volute

- Return channel

- Various leakage paths

- Multistage pumps

Modeling

PUMPAL supports two-elements-in-series (TEIS) rotor diffusion modeling, two-zone loss modeling, radial and axial stator diffusion/losses, volutes, inlet cavitation, disk friction, exit mixing, cavity leakage, and more. PUMPAL uses the same consistent model of the stage performance for design, analysis, and data reduction modes.

Integrated Performance Map Plotting

Review design performance, analysis, and test data with flexibly plotted performance maps, updated automatically with each geometric change.

Easy Editing

View the pump stage in an active, true-scale meridional view. Edit the parameters by double clicking on the component in the meridional view. Parameters can also be edited using a single text input/output file, a feature especially useful for optimization.

Tabular View of Results

View the results in a flexible, spreadsheet-like table format, customizable through separate filters. Create any number of filters, select what to display, and customize the labels as well.

Axial View with Inlet and Exit Velocity Triangles

Using the window view, view blades and velocity triangles at the impeller inlet and exit. View inlet velocity triangles for the hub, tip, or RMS radius, and exit velocity triangles for the primary and secondary zones, and mixed-out state.

A Real Fluid Program

PUMPAL calculates Real Fluid properties using a variety of equations of state options.

Direct Integration with AxCent

Start AxCent automatically from PUMPAL, with the initial meanline geometry transferred automatically to AxCent. Changes in AxCent that affect the meanline analysis will cause the meanline analysis to be rerun and all performance maps to be regenerated.

Product Support

Customer-driven Improvement

Technical Support

Documentation

PUMPAL Brochure

Perform meanline design optimization for centrifugal, mixed-flow, and axial pumps with

single or multiple stages. PUMPAL can be used to design the stage, analyze performance, refine the parameters with data reduction, and model the machine according to several performance

models.

Find Your Rep

Our Sales Offices are strategically located around the globe to service all your turbomachinery needs.

Corporate Headquarters

217 Billings Farm Road

White River Junction, VT 05001-9486

Phone: 802-296-2321

Fax: 802-296-2325

Email: sales@conceptsnrec.com

North America Software Sales

Phone: 802-280-6181

Fax: 802-296-2325

Email: droberson@conceptsnrec.com

Upcoming Events

Tradeshows, Workshops, Webinars and more.

2021 Online Centrifugal and Axial Pumps Course - Modern Design, Performance, and Problem Solving

Application-Based Learning

Date: October 18 - 29, 2021

Time: 9:30 am - 1:00 pm EDT

Course Fee: $3500 USD

This course is designed to help engineers design, test, and run pumps and systems that are more efficient, more economical, and more reliable. Engineers will come to understand the best state-of-the-art design practices and learn the latest theories on performance, cavitation, dynamic forces, and noise. The course will review the latest advances in design tools and will provide expert and relevant instruction to designers on pump design optimization. Nearly half of all the teaching is focused on actual commercial design cases with measured data for confirmation.

2021 Trade Show: ComVac Asia

Visit Concepts NREC China at the ComVac Asia

Date: October 26-29, 2021

Location: Shanghai, China

To learn more, visit https://www.comvac-asia.com/index.php?lang=en

I came to the realization that we needed some objective insight.

We were working well with the OEM but even with our combined efforts, we were struggling to get a critical compressor to pass performance on their test stand. Although I'd never directly done business with Concepts NREC I was familiar with them and their capability so I chose to contact them when I came to the realization that we needed some objective insight. Concepts NREC fielded my cold call and immediately engaged their expertise in a complex problem that was also challenged by schedule constraints. They provided increased understanding of an already complex CFD which resulted in increased confidence that the proposed solution would succeed on the next test stand attempt (which it did!). We are pleased to have had the help of Concepts NREC and now have a well-performing compressor in our process.”

Bryan Barrington

Senior Advisor - Machinery Engineering