The AS9100 Certification identifies companies who have qualified to manufacture products for the Aerospace Industry. Manufacturers who meet the extensive requirements of the AS9100 Certification have committed to maintaining quality assurances that ensure that their products are engineered, manufactured and maintained to provide the aerospace customer with a quality product.

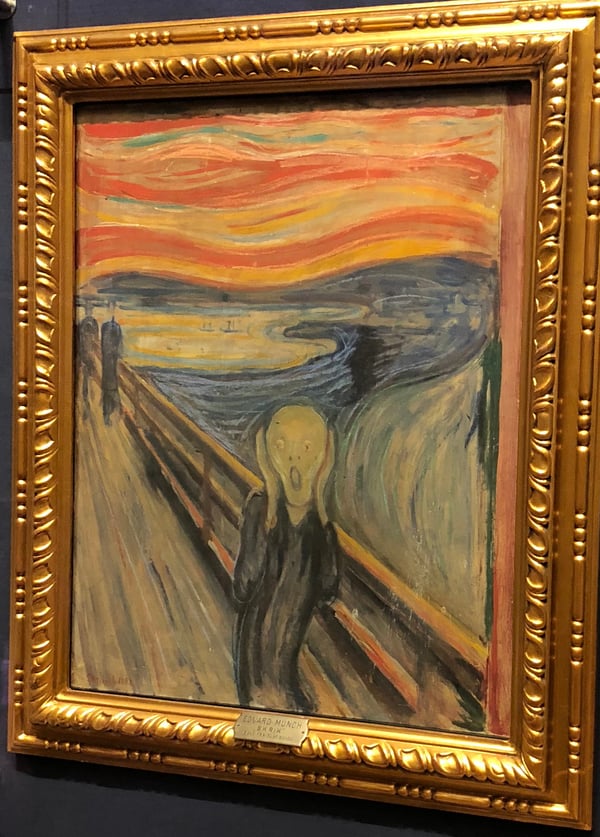

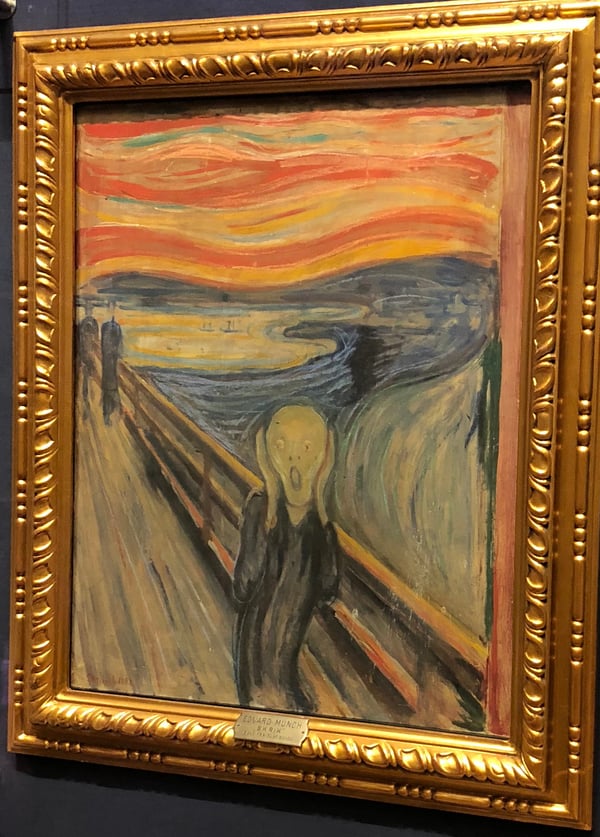

In many ways the AS9100 Certification helps companies in the aerospace industry avoid the feeling that is so aptly depicted in Edvard Munch’s painting “The Scream”. Unfortunately, in the world of engineering an aerospace event could lead to what has been calmly described as a “Bad Day” in a news conference after a catastrophic event.

One goal of the AS9100 Certification is to eliminate, reduce (and certainly trace, and never repeat), any engineering failure during the design, manufacturing, assembly, or maintenance of a product. Fortunately, most engineers are well trained and know how to avoid a major engineering failure by properly completing FEA, or CFD, and/or mechanical design analysis. These analyzes allow the design engineer to avoid selecting the wrong material for the rotational speed, pressure, temperature or corrosive environment in which the manufactured part is expected to operate. Considerable engineering time is expended avoiding these major pitfalls during the engineering design phase of the product. In fact, the attention of the engineer is so incredibly focused on avoiding significant failures that sometimes, small details “slip through the cracks”. This is when the “The Scream” becomes the loudest and this is when the procedures instituted by the AS9100 Certification becomes the most useful.

It is just as important for the engineer to turn their attention on the smallest details because these details can become significant when least expected. These “small” details must be carefully considered by the Program Manager during the internal “Kick-Off Meeting” for any project. After many years of managing projects, I have compiled list of “seemingly” minor details that deserve attention at the start of a new project. These items include the confirmed, correct rotation of the direction of a component such as a compressor or turbine, to the proper use of the gravitational constant, gc not to be confused with gravitation acceleration gg . In between these items are the seemingly simple and straightforward units such as: psi vs psia vs. psig , radians/second vs. hz and of course acfm vs scfm and Tn or tonne vs tons.

What could be simpler than knowing the rotation of the turbomachinery that you are designing? It is because of this seemingly triviality in the design that errors are made. For example, a simple hand sketch of a clockwise oriented rotation made quickly by an engineer in a kick-off meeting to simply indicated that the hand sketch drawn on the white board is a shaft and not a structural member gets taken by the client as the final direction of rotation and used as such for designing their gearbox. The error is not discovered until both machines are ready for their Critical Design Review.

The use of psia by the aerodynamic design group who reads the client’s specification to be only given as “psi” to indicate the inlet and discharge pressures of a turbine to be 73.5 psi and 14.7 psi, respectively. The pressure ratio of 5:1 is then discovered to be actually too large when it was discovered that the client intended to have the inlet pressure be 147 psig and the outlet 14.7 psig.

The natural frequency of the shaft is given by the client as 2000 Hz and yet this value is given with the typical parameter, ω, which is most often given in textbooks as representing natural frequency but has units of radians per second. In fact, radians per second is actually: 1/2π Hz. Engineering trivia question: What is the only engineering unit that comes and goes, like a ghost, in an engineering equation?” Ans.: Radians as in: Tip Velocity, V [m/s] = ω [radians/s] x radius [m].

The client’s flowrate into the compressor is given as 4,000 cfm. The absolute first question to the client should be: “Is this actual cfm (acfm) or standard cfm (scfm)?” The amount of mass flowrate through the compressor can be very different if the value is acfm vs. scfm depending on the temperature and pressure at the inlet of the compressor.

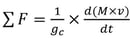

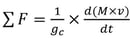

And here is my personal favorite: the use (or nonuse) of gc as the gravitational constant, not to be confused with gg, acceleration of a mass by the gravity attraction of the earth and the mass. Newton’s Law is best defined in equation form as::  or for the purist in all of us:

or for the purist in all of us:  . The parameter, gc is needed to keep the calculation of the force (F) correct. If you work in the Imperial unit system (lbf, ft, lbm) rather than metric units (N, m, kg) the value of gc= 32.19 lbm-ft/lbf-s2 as compared to 1 kg-m/N-s2. Forgetting to use gc when working in the Imperial unit system can cause serious miscalculation of forces.

. The parameter, gc is needed to keep the calculation of the force (F) correct. If you work in the Imperial unit system (lbf, ft, lbm) rather than metric units (N, m, kg) the value of gc= 32.19 lbm-ft/lbf-s2 as compared to 1 kg-m/N-s2. Forgetting to use gc when working in the Imperial unit system can cause serious miscalculation of forces.

Just ask the NASA engineers who used both metric and imperial unit systems when designing the Mars Climate Orbiter that crashed upon trying to enter Mars orbit in 1999. Imagine “The Scream” on 200 NASA faces.

Concepts NREC is ISO 9001:2008 and AS9100C certified and committed to providing our customers with products and services. If you need any help with your aerospace projects, contact us.