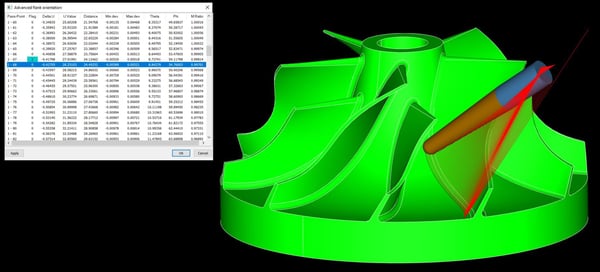

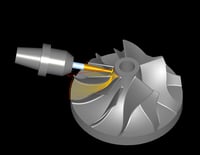

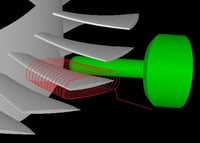

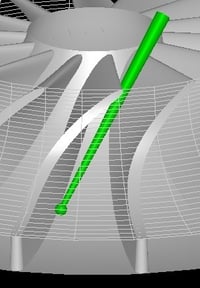

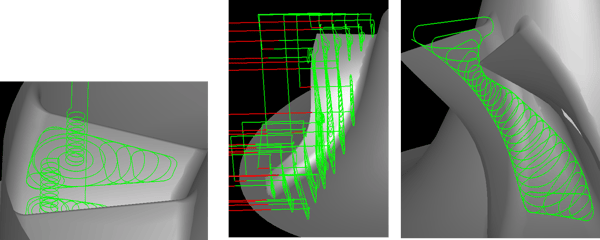

- Achieve faster roughing using 3-axis toolpaths at an arbitrary angle (3+2)

Inbound Strategy

Meet all of your inbound goals and objectives.

Unlimited Power

Build as many pages as you need for your high-conversion website.

Built for Everyone

Easy-of-use ensures new users learn to use prototyping tools.

White-Glove Service

The design sprints are a white glove service.

Quick Prototyping

Choose from a vast selection of modules and drag-and-drop.