Manufacturing Software Solutions

We provide the tools to take your design from digital to physical

Concepts NREC’s machining software solutions are industry-focused. By focusing our CAM software tools on specific challenges, we streamline the programming process so that you can spend less time behind a computer and start cutting metal sooner than you thought possible.

Turbomachinery Manufacturing Solutions

Tap into 60+ years of turbomachinery experience with MAX-PAC™.

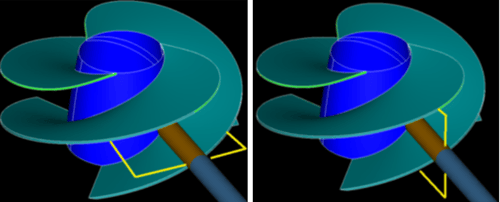

Manufacturing turbomachinery can be a challenging endeavor. Whether you want to flank mill a ruled blade to a mirror finish or use toroidal and barrel cutters to efficiently finish a turbine blade, we have a module to solve the challenges that are unique to these applications. These geometry-specific products allow you to configure your CAM system for any type of turbomachinery.

Input geometry is critical for producing high-quality toolpaths. That’s why our workflow starts with using CAD tools to prepare geometry and build a reliable and repeatable configuration.

From there it only takes a few clicks to generate an initial toolpath. Our collision avoidance algorithms do the hard work of orienting the tool so that you can focus on fine tuning to produce a toolpath that looks exactly the way you want it to.

As you build your operations, our integrated material removal and machine tool simulation tools enable you to further optimize your toolpaths so that you don’t waste valuable time on your machine.

Application Support Solutions

New to turbomachinery? Stuck on a challenging part?

With Agile Product Support we will be right by your side teaching you the basics and helping you push boundaries with more advanced techniques. And we’ll always make sure you have access to the latest tools and features.

Agile Products Support (APS)

APS is Concepts NREC’s software maintenance and support program that elevates us from just a software provider to a valued partner.

An APS subscription is included with all annual licenses and is a highly-recommended option for perpetual software licenses. Every software customer is supported for one month following purchase for any installation questions that may arise. Learn more on the Agile Products Support Membership Benefits Datasheet.

- Free software updates

- One business day response times

- Expert technical assistance

- Discounted professional development course

- Annual balloting system for development planning

- Annual Meetings

CAM Software Brochure

Our integrated design and manufacturing software tools provide designers with a cost-effective, concurrent development approach that balances issues of performance, reliability, cost-effectiveness, and manufacturability.