Welcome Thomas Kudla, Senior Software Engineer at Concepts NREC read more Kudla will develop and maintain AxCent®, the company’s flagship software product used for detailed 3D geometric design and...

A blog on what's new, notable, and next in turbomachinery

By Concepts NREC

Feb 17, 2026

Welcome Thomas Kudla, Senior Software Engineer at Concepts NREC read more Kudla will develop and maintain AxCent®, the company’s flagship software product used for detailed 3D geometric design and...

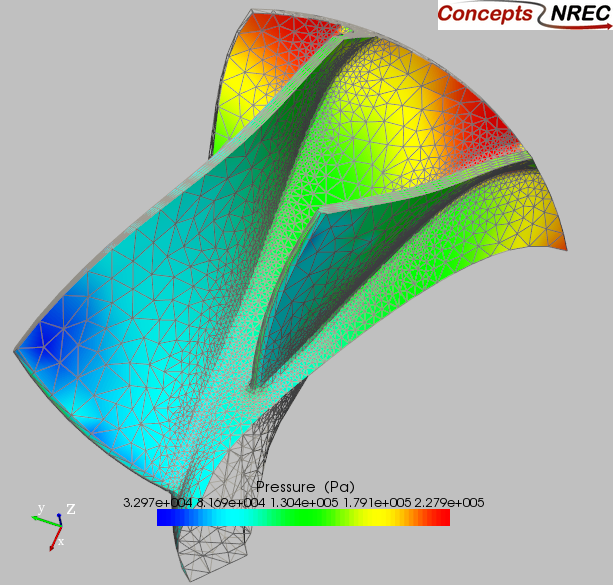

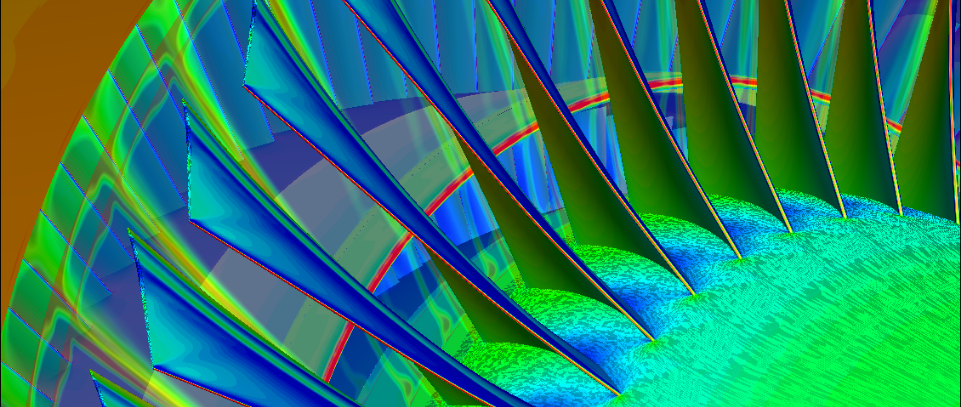

B.Eng in Mechanical Engineering from Huddersfield Polytechnic [now University] in the UK. Worked for many years applying robust Engineering solutions to the problems experienced by highly loaded gas and steam turbine components for companies such as GEC Asthom and GE Energy. Gained much experience applying tools such as CFD and FEA analyses to estimate, understand, and subsequently extend, the life of components exposed to the extremely hostile conditions found both within low NOx combustors and the gas turbine hot gas path. Some of the projects he was involved in included the optimization of gas fuel pre-mixing to ensure stable combustion, developing combustor liner and turbine blade film cooling strategies in order to make component life requirements, the thermo-mechanical design of fir-tree roots and the aero/thermo/mechanical design of multi-pass internal cooling passage turbine blades. Aero, thermal and mechanical analysis methods development. He now manages and participates in the development of our fully integrated structural design and analysis software, Pushbutton FEA.

By John Keeling

May 3, 2017

The biggest reason to use an integrated turbomachinery design and analysis environment is speed. Basically, having everything you need in one place makes a big difference!